Circulating heat and power cogeneration system for stair type heat supplying supercritical carbon dioxide used for sodium-cooled fast reactor

A carbon dioxide, sodium-cooled fast reactor technology, applied in the direction of reactors, nuclear power generation, cooling devices, etc., can solve the problems of low thermal cycle efficiency, inability to achieve cascade heating, and safety hazards in sodium-water working medium heat transfer, etc. The effect of improving safety, avoiding technical difficulties, and slow contact response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

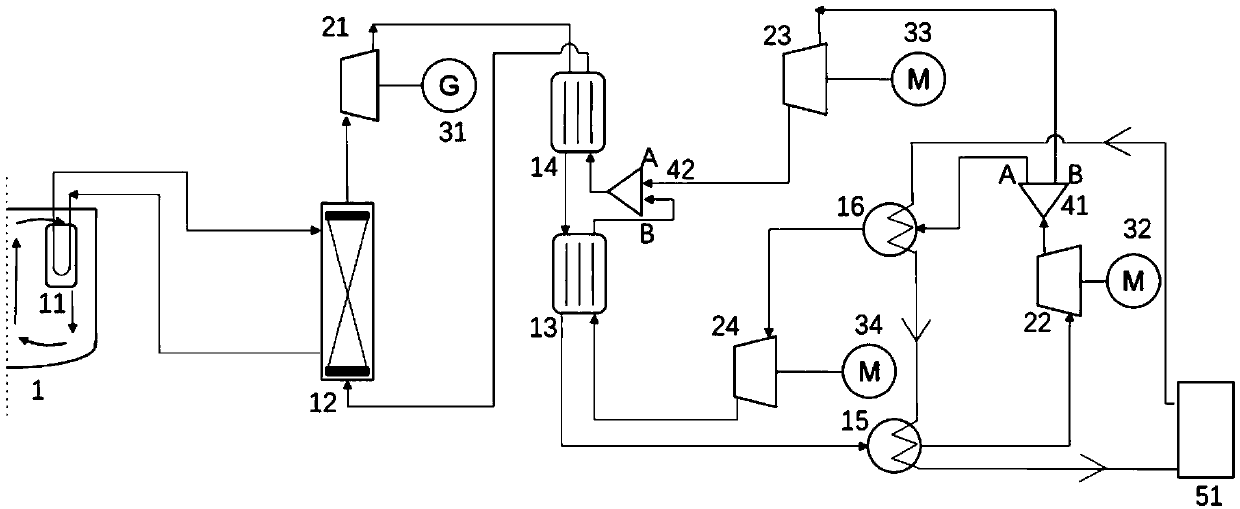

[0021] Specific implementation mode 1, such as figure 1 As shown, the cascade heating supercritical carbon dioxide cycle combined heat and power system for sodium-cooled fast reactors in this embodiment includes a heat source, a first loop, a second loop, a cascade heating loop, a sodium-sodium heat exchanger 11, a sodium - carbon dioxide heat exchanger 12, main cooler 15, intercooler 16 and heat supply pipe network interface 51;

[0022] The first loop absorbs the heat from the heat source through the sodium-sodium heat exchanger 11, and then exchanges the heat to the second loop through the sodium-carbon dioxide heat exchanger 12. The second loop uses the heat to generate power, and the remaining heat after power generation passes through the main cooler. 15 and the intercooling air 16 are exchanged to the cascade heating circuit, and the cascade heating circuit is communicated with the heating pipe network interface 51.

[0023] Further: the heat source includes a sodium-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com