End cover and compressor

An end cover and compression device technology, applied in the field of compression, can solve the problems of large oil output of the compressor, unstable oil level, low airflow velocity, etc., to reduce pressure drop loss, improve oil and gas separation efficiency, and reduce resistance to resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the purpose, structure and function of the present invention, an end cover and a compressor of the present invention will be further described in detail below in conjunction with the accompanying drawings.

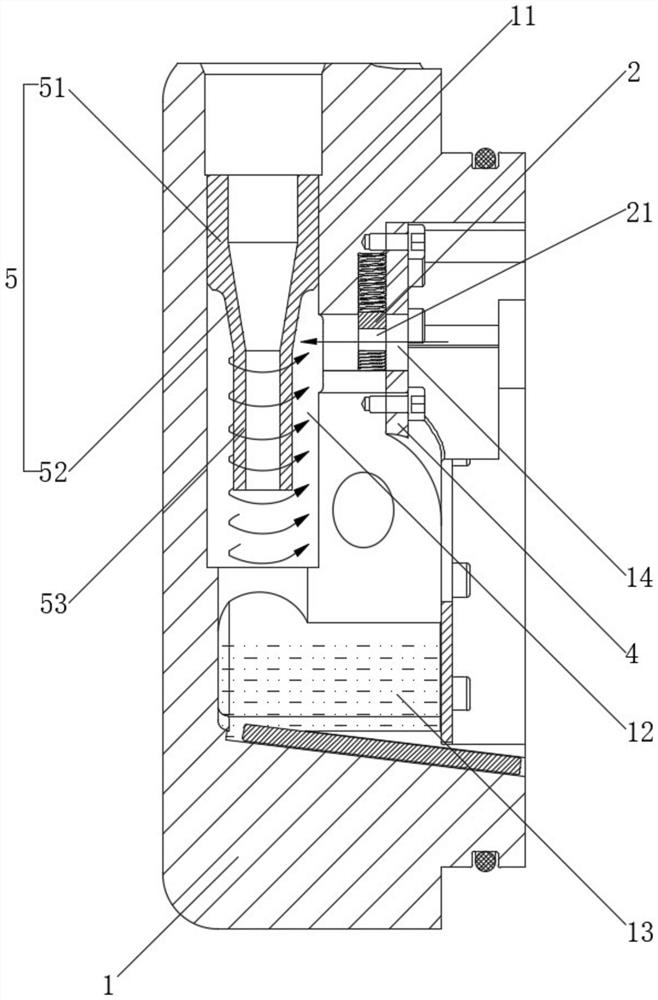

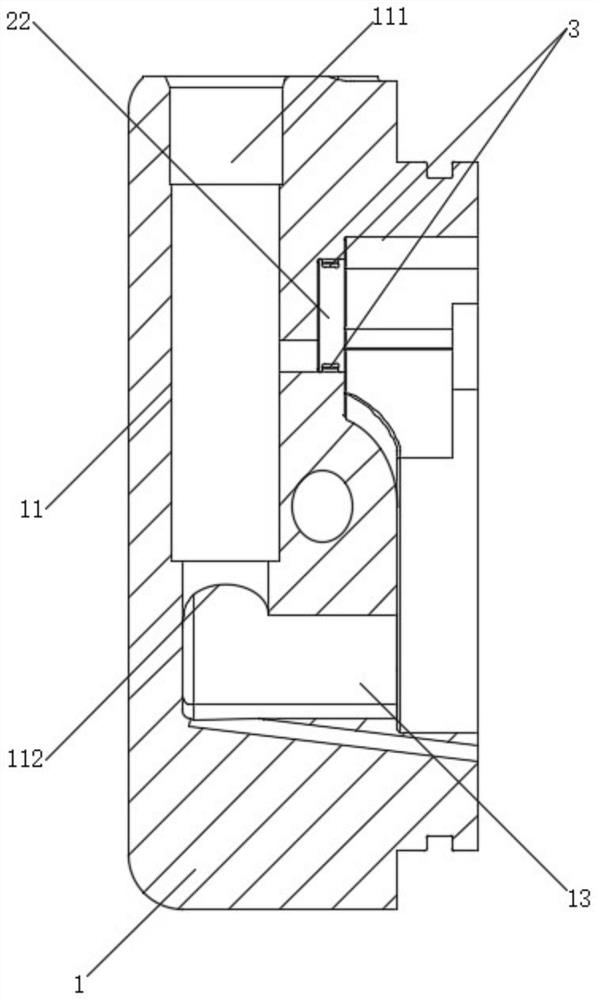

[0025] Such as figure 1 As shown, the compressor of the present invention, the scroll compressor, includes a movable disk and a static disk that are meshed with each other. Compression is performed, and the oil-air mixture enters the separation chamber 12 from the air inlet 14 on the end cover 1 . In the separation chamber 12, the oil and gas separation device separates the oil and gas, and the separated gas is discharged from the exhaust port 111 at one end of the exhaust channel 11, and the separated oil passes through the oil storage tank through the oil return port 112 at the other end of the exhaust channel 11. 13 flows back to the pump body for lubrication.

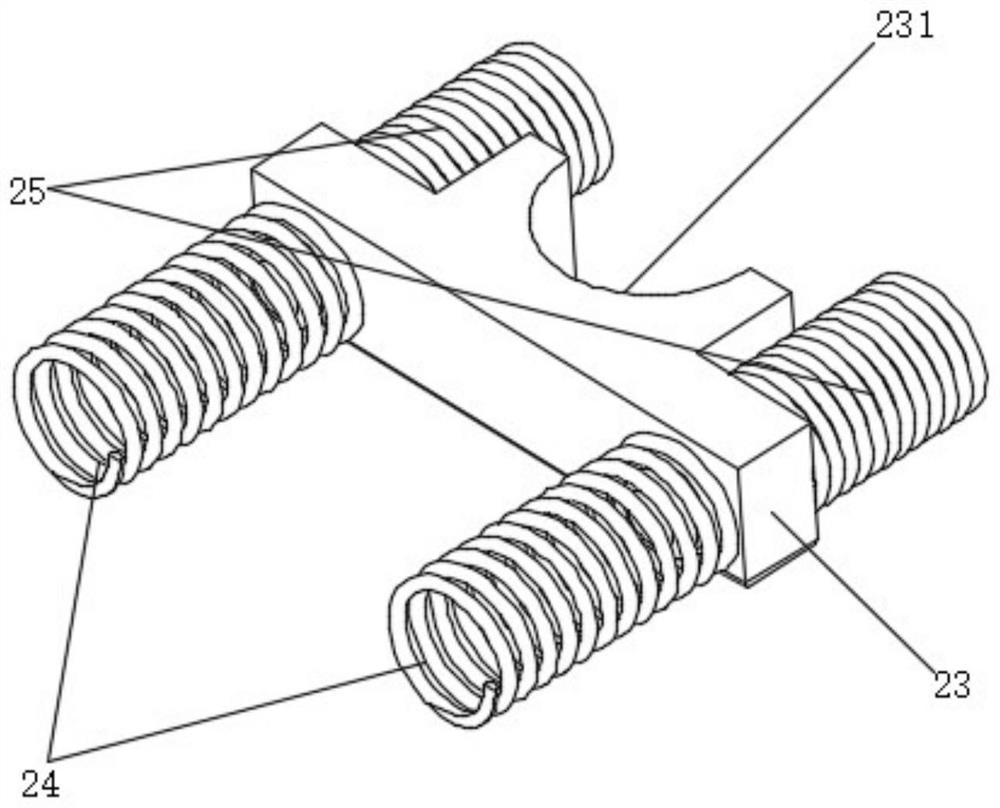

[0026] In order to adjust the flow rate of the air inlet 14 according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com