Hollow fiber permeating and vaporizing film and preparation method

A pervaporation membrane, hollow technology, used in chemical instruments and methods, semi-permeable membrane separation, membranes, etc., can solve the problems of long cycle, easy swelling of membranes, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

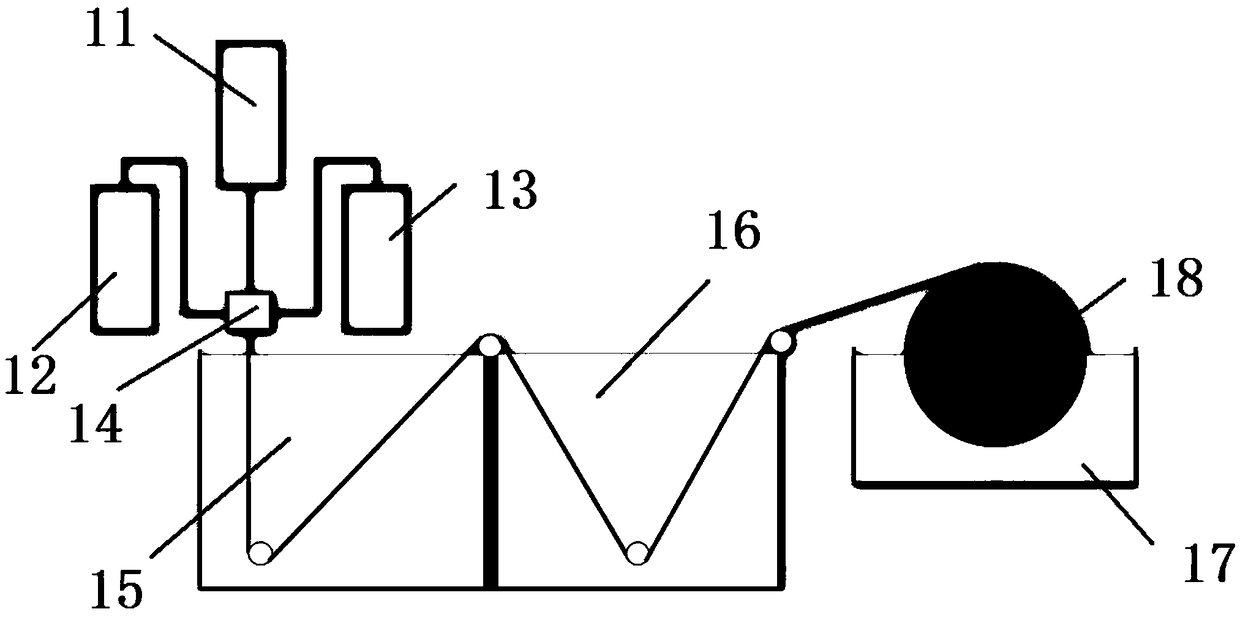

Method used

Image

Examples

Embodiment 1

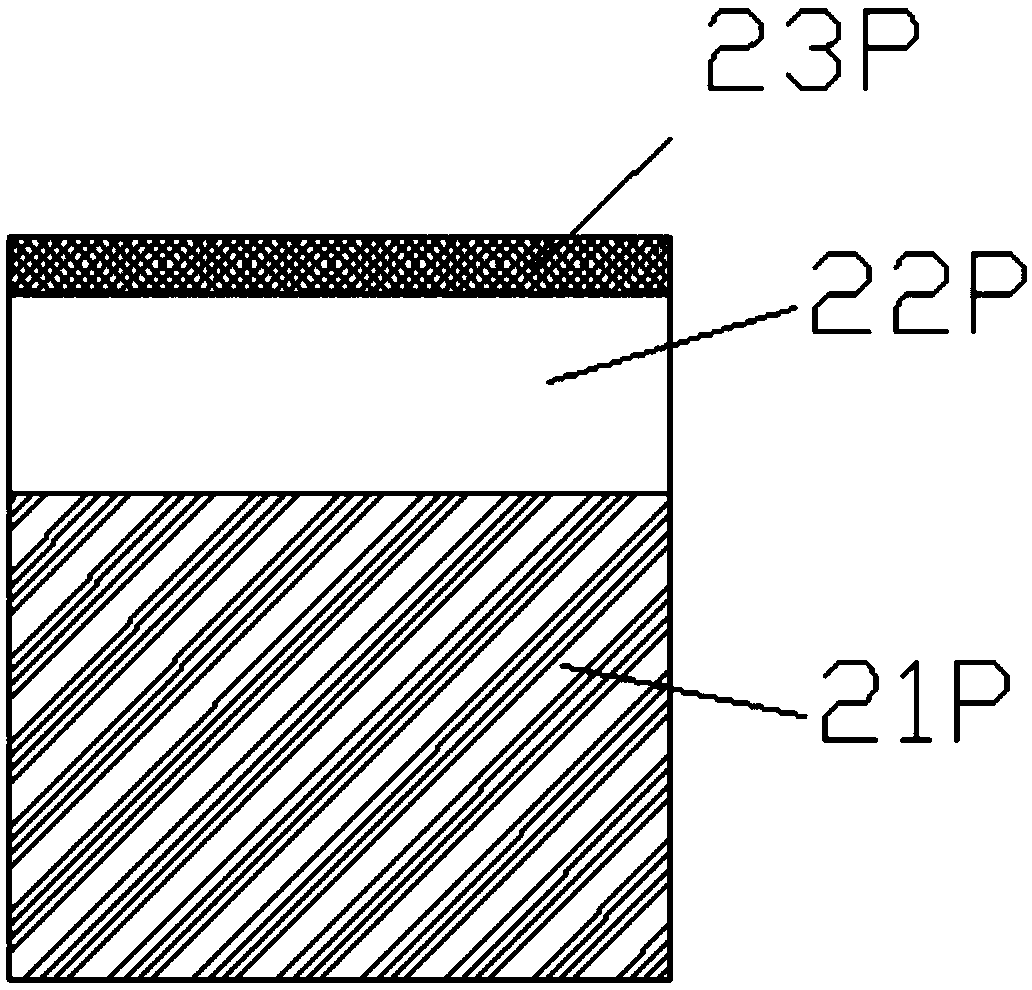

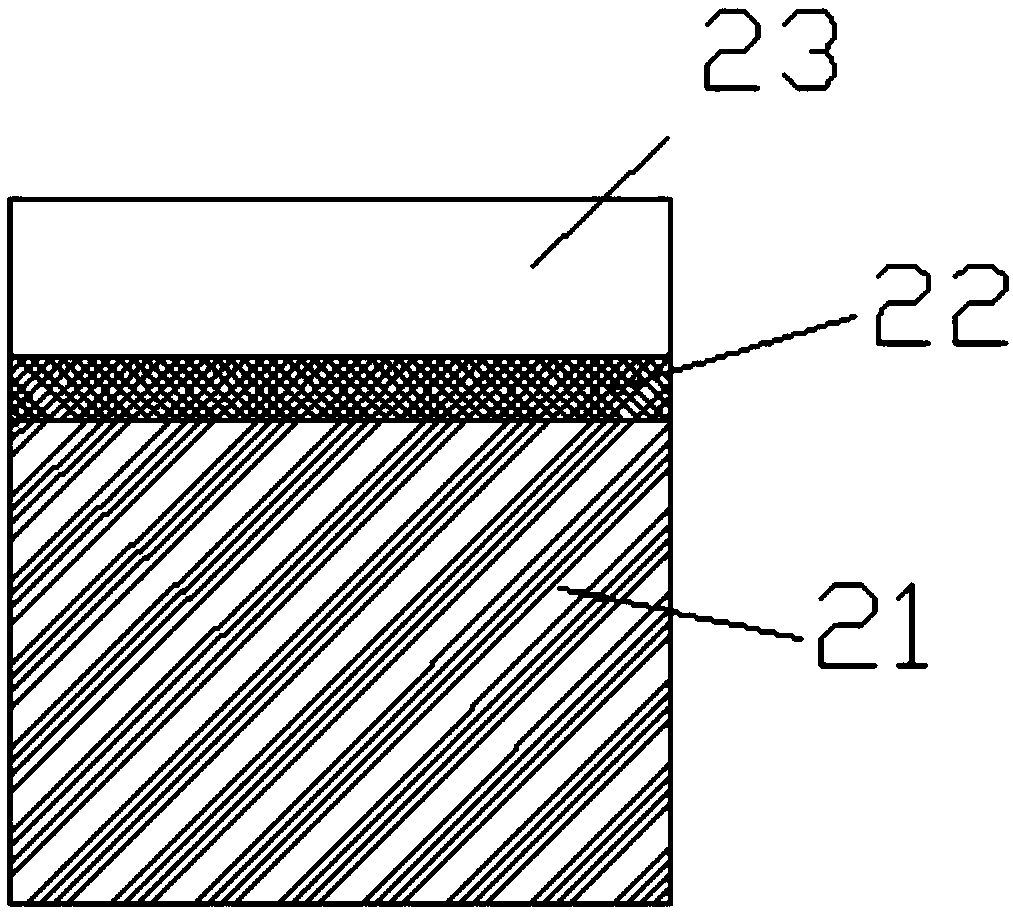

[0062] The chosen formula is:

[0063] Outer layer casting solution formula: a mixed solution of sulfonated polyphenylsulfone and n-methyl-2-pyrrolidone, wherein the mass ratio of the sulfonated polyphenylsulfone is 30%, and the n-methyl-2-pyrrolidone The mass ratio is 69%;

[0064] Inner layer casting solution formula: a mixed solution of polyphenylsulfone, ethylene glycol and n-methyl-2-pyrrolidone, wherein the mass ratio of polyphenylsulfone is 20%, and the mass ratio of ethylene glycol is 15% , the mass ratio of the n-methyl-2-pyrrolidone is 65%;

[0065] Core liquid formula: n-methyl-2-pyrrolidone, water and ethylene glycol, wherein the mass ratio of the n-methyl-2-pyrrolidone is 90%, the mass ratio of the water is 5%, the ethyl alcohol The mass ratio of glycol is at 5%;

Embodiment 2

[0067] The difference from Example 1 is that the mass ratio of the sulfonated polyphenylsulfone to n-methyl-2-pyrrolidone is 32:68.

Embodiment 3

[0069] The difference from Example 1 is that the mass ratio of the polyphenylsulfone, the ethylene glycol and the n-methyl-2-pyrrolidone is 22:15:63.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com