A device for gas impact coupling porous roof stamping

A technology of gas pressure stabilization and top plate, which is applied in the direction of measuring devices, instruments, particle and settlement analysis, etc., can solve the problems of long vibration time, waste of product quality, impact, etc., and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

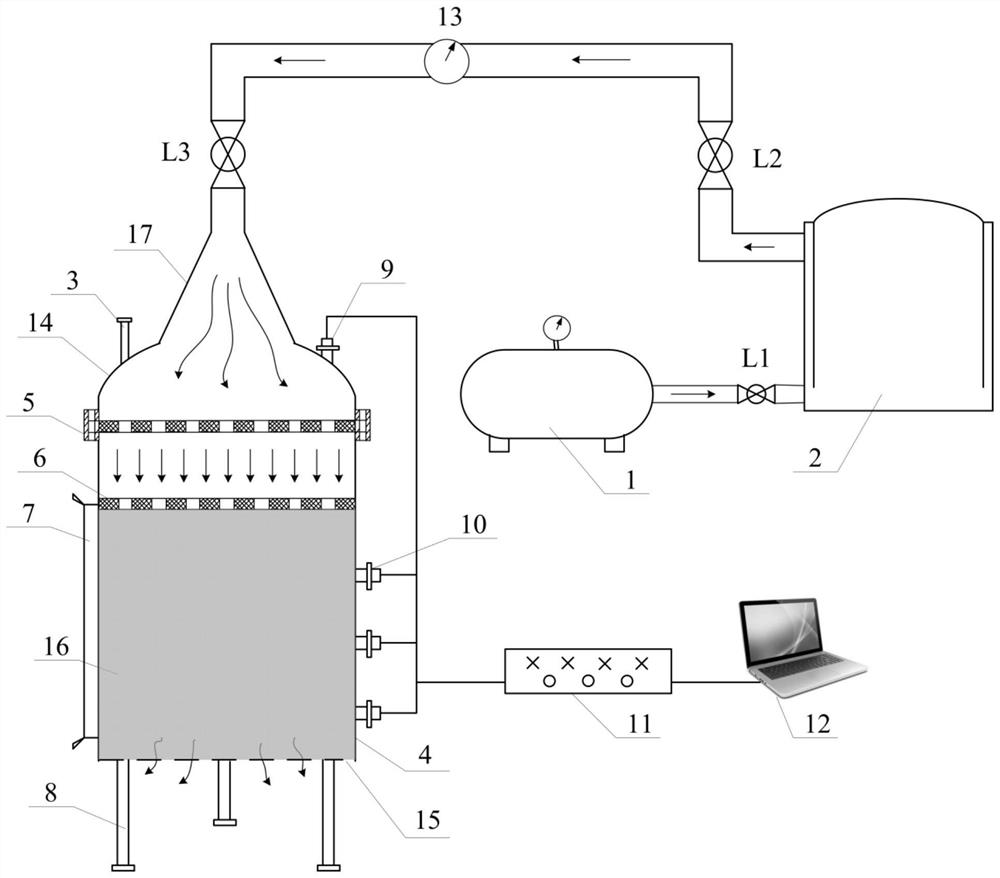

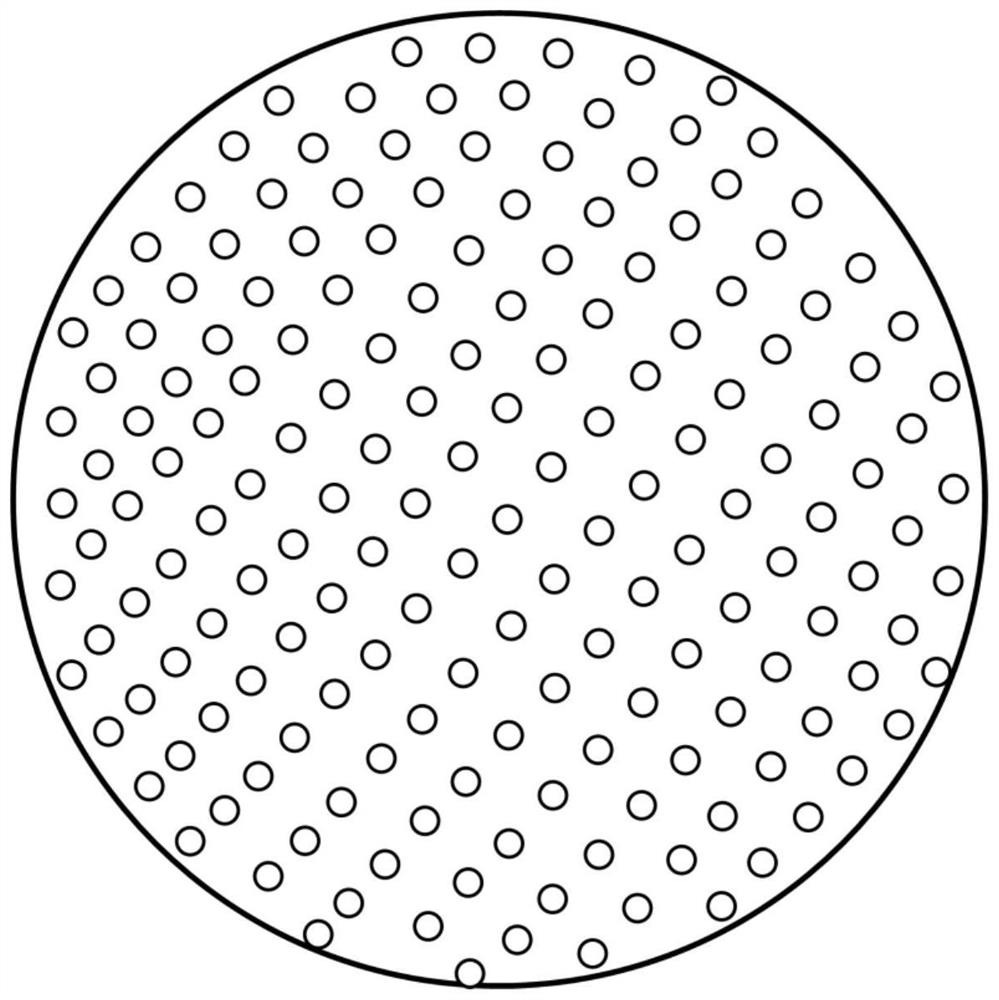

[0055] A gas impact coupled porous top plate stamping device to achieve particle packing densification, such as figure 1 As shown, it mainly includes an air compressor 1, a gas storage tank 2, a cylinder body 4, legs 8, an upper head 14, a movable porous top plate 6, an air pressure sensor and a pressure sensor. The air compressor 1 is connected to the gas stabilizing storage tank 2 through pipelines, and the gas stabilizing storage tank 2 is connected to the cylinder body 4 through pipelines. The inside of the cylinder body 4 is used to place particles that need to be Into the inside of the cylinder 4, the size of the movable porous top plate 6 is as large as the cross-sectional area of the cylinder body. The movable porous top plate 6 is provided with a plurality of through holes, and the upper end of the cylinder 4 passes through the flange 5 and the upper head 14. Sealed connection, an air inlet 17 is provided in the center of the top of the upper head 14, the gas storag...

Embodiment 2

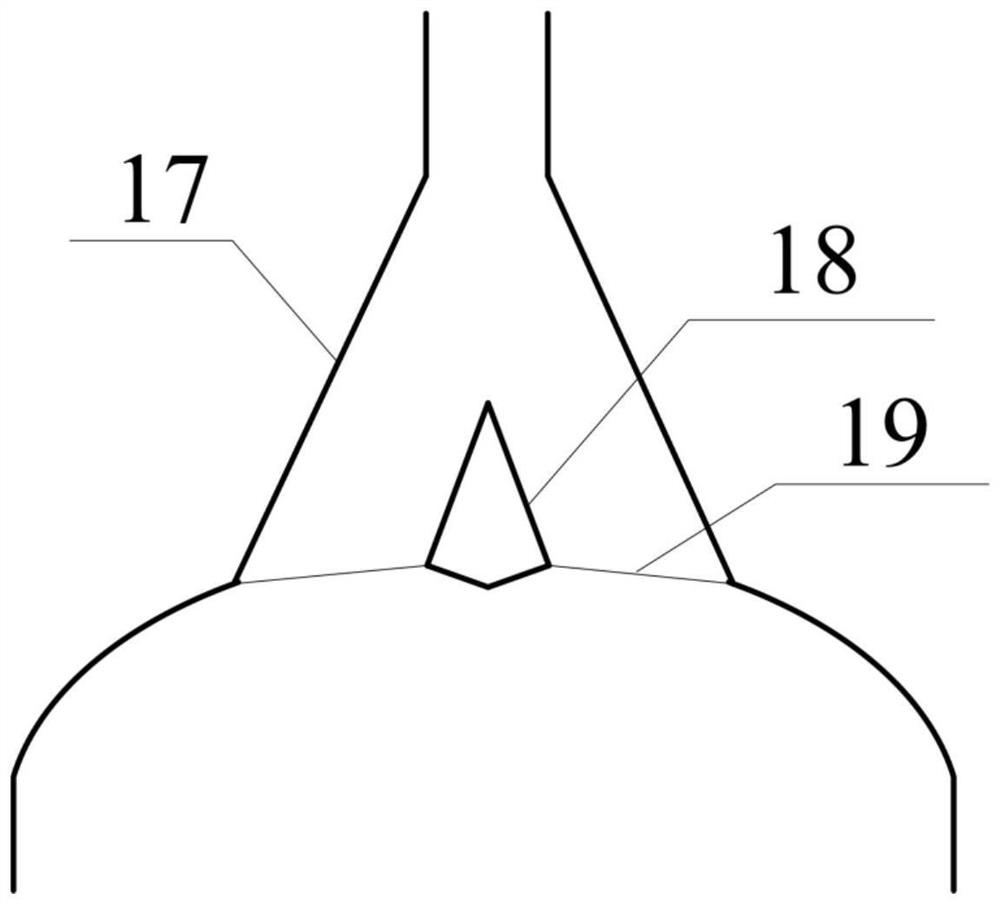

[0069] This embodiment is based on Embodiment 1, and a gas diversion cone 18 is fixedly installed directly below the air inlet in the air inlet 17, and the diversion cone is fixed by a diversion cone bracket 19. The schematic diagram is as follows image 3 As shown, the guide cone bracket 19 is fixed inside the upper head 14 .

[0070] When the high-pressure gas flows through the diversion cone 18 for diversion, it acts on the movable porous roof and quickly flows through the impacting particle medium. Various particles are piled up and densified under the impact of the high-pressure gas, and finally the gas is discharged through the openings at the bottom. Further avoiding the formation of pits on the surface of the particle densification layer due to excessive local pressure caused by uneven gas distribution.

[0071] The movable porous roof of the present invention not only provides a certain gravity for pressing the particles, but also provides mechanical pressure under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com