Device and method for preparing ordered mesoporous carbon-metal composite material and co-producing biological carbon from solid waste biomass

A metal composite material, ordered mesoporous technology, applied in the fields of biofuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of difficult to achieve integrated continuous operation, high production costs, workers and environmental hazards, and promote industrialization. Promotion and application to achieve the effect of secondary utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

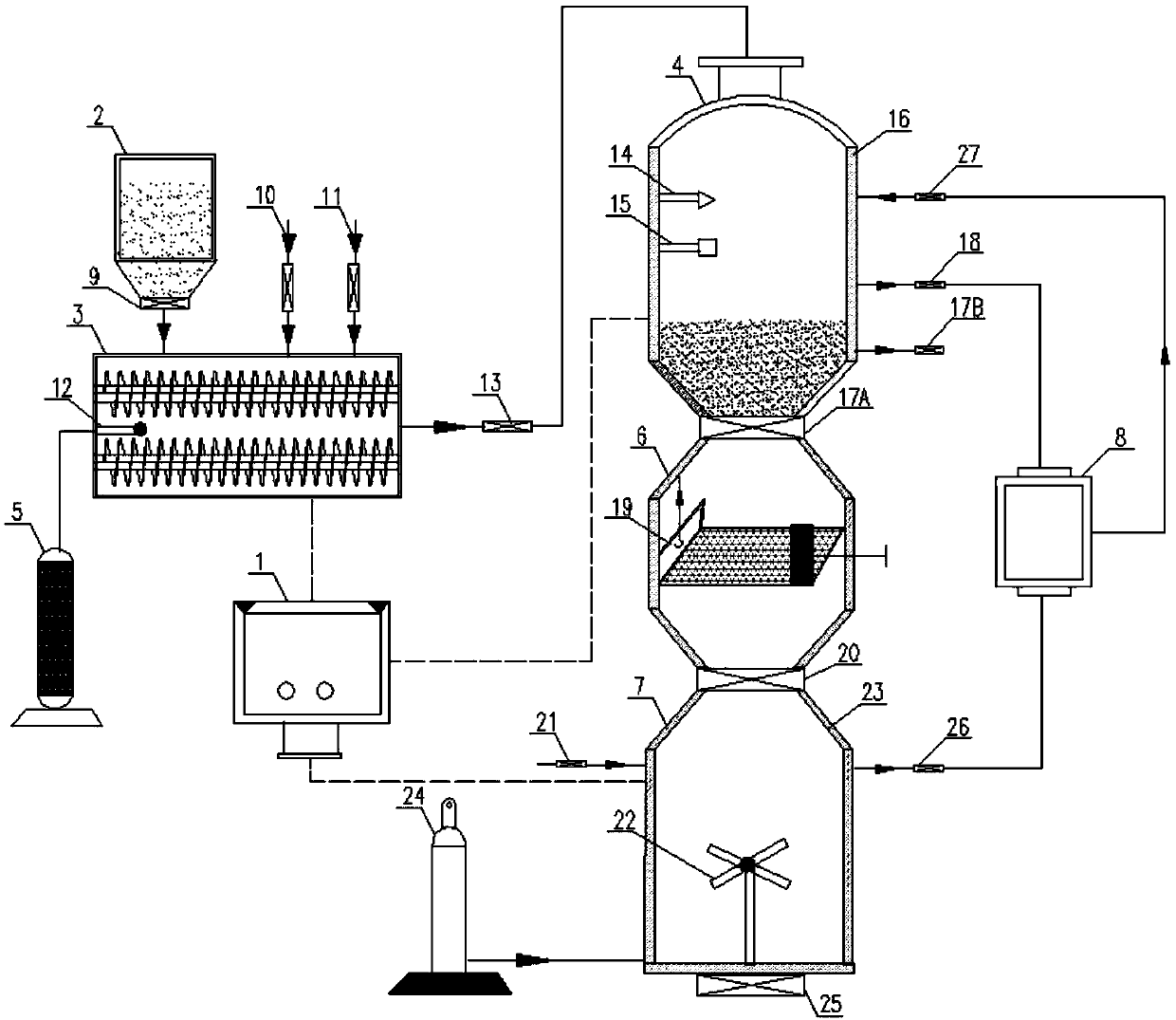

[0041] 100 g of agricultural solid waste corncob powder with a particle size of 40 meshes is transported to the double-screw mixing conveying device 3 through the raw material discharge valve 9 of the feeding unit 2 . Open metal salt feed valve 10 and add 5g CoCl 2 and 5g FeCl 3 Metal salt, and synchronously open the dilute acid feed valve 11, according to the dilute acid of 10:1 and the liquid-solid ratio of corncob, add concentration and be 3% H 2 SO 4 . Start the double-helix stirring paddle to fully stir the corncob powder, dilute H 2 SO 4 、CoCl 2 and FeCl 3 metal salts. Synchronously turn on the pH sensor 12 and the pH regulator 5 to regulate the pH of the mixed solution in real time. After fully mixing, open the mixing discharge valve 13 and transport the solid-liquid mixture to the multifunctional reactor 4, and open the pressure sensor 14, the temperature sensor 15 and the high temperature pressurization-microwave heating device 16 of the multifunctional reacto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com