A kind of sheath material for underground communication cable and preparation method thereof

A sheath material and underground communication technology, applied in the direction of building insulation materials, circuits, electrical components, etc., can solve the problems that the softness and corrosion resistance cannot be improved at the same time, so as to improve the volume resistivity performance and the fracture tensile strain Performance, the effect of improving soft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The sheath material for underground communication cables includes raw materials in the following proportions by weight: 40 parts of polyvinyl chloride, 10 parts of carbon fiber, 23 parts of moisture-proof filler, 16 parts of acid and alkali corrosion-resistant filler, and 17 parts of flexible filler;

[0054] Wherein, the above-mentioned moisture-proof filler is composed of 10 mass parts of petroleum asphalt, 5 mass parts of natural asphalt and 8 mass parts of butyl rubber;

[0055] The above-mentioned acid and alkali corrosion-resistant filler is composed of 5 parts by mass of epoxy-phenolic paint, 3 parts by mass of polyurethane paint, 5 parts by mass of epoxy resin coating and 3 parts by mass of three polyethylene anticorrosive coatings;

[0056] The above-mentioned flexible filler consists of 2 mass parts of epoxy soybean oil, 3 mass parts of epoxy fatty acid octyl ester, 4 mass parts of tricresyl phosphate, 3 mass parts of triphenyl phosphate and 5 mass parts of tri...

Embodiment 2

[0064] The sheath material for underground communication cables includes raw materials in the following proportions by weight: 50 parts of polyvinyl chloride, 15 parts of carbon fiber, 33 parts of moisture-proof filler, 23 parts of acid and alkali corrosion-resistant filler, and 24 parts of flexible filler;

[0065] Wherein, the above-mentioned moisture-proof filler is composed of 15 parts by mass of petroleum pitch, 6 parts by mass of natural pitch and 12 parts by mass of butyl rubber;

[0066] The above-mentioned acid and alkali corrosion-resistant filler is composed of 6 mass parts of epoxy-phenolic paint, 4 mass parts of polyurethane paint, 8 mass parts of epoxy resin coating and 5 mass parts of three polyethylene anticorrosive coatings;

[0067] Above-mentioned flexible filler is made of the epoxy soybean oil of 3 mass parts, the octyl epoxy fatty acid of 4 mass parts, the tricresyl phosphate of 7 mass parts, the triphenyl phosphate of 4 mass parts and the trimellitic acid...

Embodiment 3

[0075] The sheath material for underground communication cables includes raw materials in the following proportions by weight: 80 parts of polyvinyl chloride, 20 parts of carbon fiber, 43 parts of moisture-proof filler, 31 parts of acid and alkali corrosion-resistant filler, and 28 parts of flexible filler;

[0076] Wherein, the above-mentioned moisture-proof filler is composed of 20 mass parts of petroleum asphalt, 8 mass parts of natural asphalt and 15 mass parts of butyl rubber;

[0077] The above-mentioned acid and alkali corrosion-resistant filler is composed of 8 mass parts of epoxy-phenolic paint, 5 mass parts of polyurethane paint, 10 mass parts of epoxy resin coating and 8 mass parts of three polyethylene anticorrosive coatings;

[0078] Above-mentioned flexible filler is made of the epoxy soybean oil of 5 mass parts, the epoxy fatty acid octyl ester of 5 mass parts, the tricresyl phosphate of 7 mass parts, the triphenyl phosphate of 5 mass parts and the trimellitic ac...

PUM

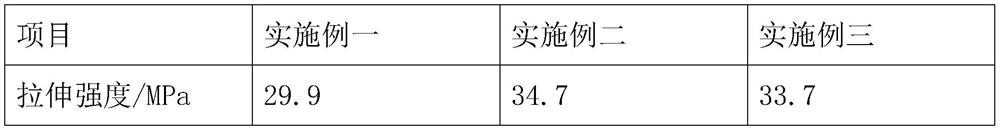

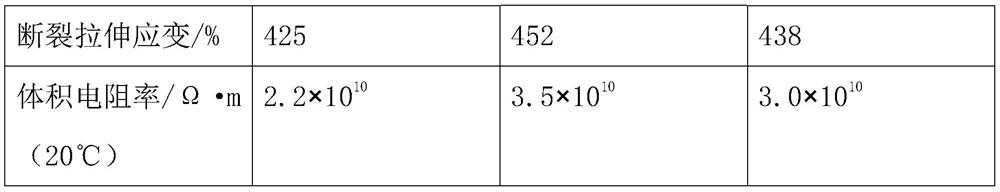

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com