Preparation method of plate out-free external lubricant

An external lubricant and pressure analysis technology, which is applied in the field of polymer material processing, can solve the problems of labor and time consumption, product scrapping, product surface defects, etc., reduce the number of cleaning and filter replacement, and the structure of the external lubrication film is firm , Good effect of external lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

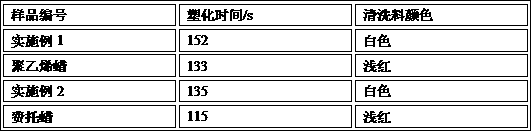

Examples

Embodiment 1

[0018] A preparation method of a pressure-separation-free external lubricant, the method comprising the steps of:

[0019] (1) Dissolve 3.5kg of allyl urea and 0.3kg of a 1:1 mixture of lauryl peroxide and dicumyl peroxide in a small amount of acetone solution, and then mix the two evenly before use;

[0020] (2) Add 100kg of polyethylene wax to the reactor, melt it and keep it at 140°C, then start to blow nitrogen into the reactor, and after the air in the reactor is completely driven out, start to drop the mixed solution;

[0021] (3) After the dropwise addition, react at 140°C for one hour. Continue to protect with nitrogen during this process. Stop heating after the reaction is over. When the temperature drops to about 100°C, pour the product into a container filled with cold water. And vigorously stirred, filtered to get the crude product;

[0022] (4) Take the crude product, add xylene, heat to dissolve, then add acetone to it to form a white precipitate, wash the filte...

Embodiment 2

[0024] A preparation method of a pressure-separation-free external lubricant, the method comprising the steps of:

[0025] (1) Dissolve 4.5kg of allyl urea and 0.35kg of benzoyl peroxide in a small amount of acetone solution, then mix the two evenly before use;

[0026] (2) Add 100kg of Fischer-Tropsch wax into the reactor, keep it at 120°C after melting, and then start to blow nitrogen into the reactor, and after the air in the reactor is completely driven out, start to drop the mixed solution;

[0027] (3) After the dropwise addition, react at 120°C for one hour. Continue to protect with nitrogen during this process. After the reaction, stop heating. When the temperature drops to about 100°C, pour the product into a container filled with cold water. And vigorously stirred, filtered to get the crude product;

[0028] (4) Take the crude product, add xylene, heat to dissolve, then add acetone to it to form a white precipitate, wash the filter cake with acetone for 3 times afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com