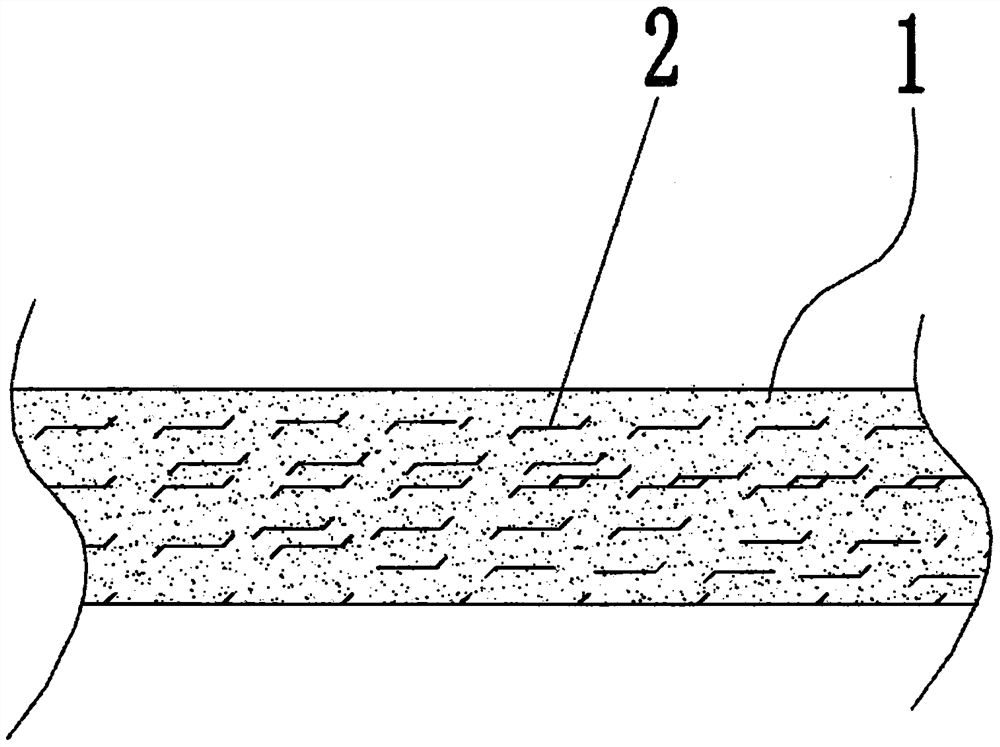

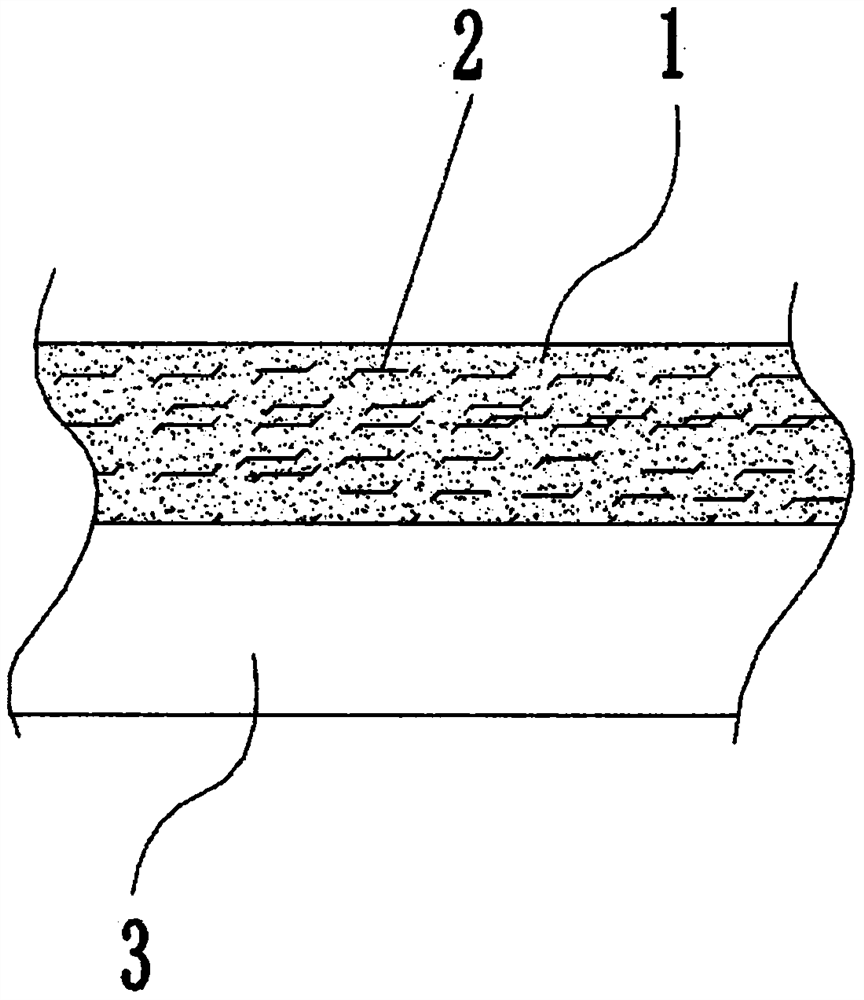

A kind of fiber modified board and its application

A fiber modification, board technology, applied in the direction of fiber chemical characteristics, monocomponent polyester rayon, textiles and papermaking, etc., can solve problems such as low surface, scratch marks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of fiber modified plate, it comprises the steps:

[0029] (1) Dry the polyester chips at 170°C for 4 hours. During the drying process, inert gas is continuously introduced, so that the polyester chips are dried in an inert gas atmosphere. The moisture content of the dried polyester chips is low at 300ppm;

[0030] (2) According to chemical composition (Pt 24 Al 34 Fe 37 P 24 ) Put Pt, Al, Fe and P raw materials into a vacuum melting furnace, melt at a temperature of 1000°C, fill in argon during the melting process and melt under an argon atmosphere, wherein the components are melted and mixed After that, keep the constant temperature for 1.5 hours, then cool it down to below 400°C with the furnace, then raise the temperature to 1000°C to continue the smelting process, repeat 3 times, cool the smelted product to room temperature with the furnace, and then grind it into a particle size less than 0.1 mm to obtain alloy powder, wherein the ...

Embodiment 2

[0035] A kind of preparation method of fiber modified plate, it comprises the steps:

[0036] (1) Dry the polyester chips at 160°C for 4.5 hours. During the drying process, inert gas is continuously introduced to dry the polyester chips in an inert gas atmosphere. The moisture content of the dried polyester chips is less than 300ppm;

[0037] (2) According to chemical composition (Pt 23 Al 37 Fe 42 P 26 ) Put Pt, Al, Fe and P raw materials into a vacuum melting furnace, melt at a temperature of 1100°C, fill in argon during the melting process and melt under an argon atmosphere, wherein the components are melted and mixed After that, keep the constant temperature for 1.5 hours, then cool it down to below 400°C with the furnace, then raise the temperature to 1100°C to continue the smelting process, repeat 2 times, cool the smelted product to room temperature with the furnace, and then grind it into a particle size less than 0.1 mm to obtain alloy powder, wherein the purity ...

Embodiment 3

[0042] A kind of preparation method of fiber modified plate, it comprises the steps:

[0043] (1) Dry the polyester chips at 150°C for 5 hours. During the drying process, inert gas is continuously introduced to make the polyester chips dry in an inert gas atmosphere. The moisture content of the dried polyester chips is low at 300ppm;

[0044] (2) According to chemical composition (Pt 27 al 32 Fe 34 P 23 ) Put Pt, Al, Fe and P raw materials into a vacuum melting furnace, melt at a temperature of 900°C, fill in argon during the melting process and melt under an argon atmosphere, wherein the components are melted and mixed After that, keep the constant temperature for 1.5 hours, then cool it down to below 400°C with the furnace, then raise the temperature to 900°C to continue the smelting process, repeat 4 times, cool the smelted product to room temperature with the furnace, and then grind it into a particle size less than 0.1 mm to obtain alloy powder, wherein the purity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com