Ionic polymer metal complex base film surface directionally coarsening device

A metal composite, ionic polymer technology, used in grinding devices, metal processing equipment, grinding machine tools, etc., can solve many uncontrollable factors, it is difficult to ensure the directionality and uniformity of the surface morphology of the base film, and limit IPMC materials. performance and other issues, to achieve the effect of simple device structure, mechanization and standardization, and uniform distribution of abrasives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

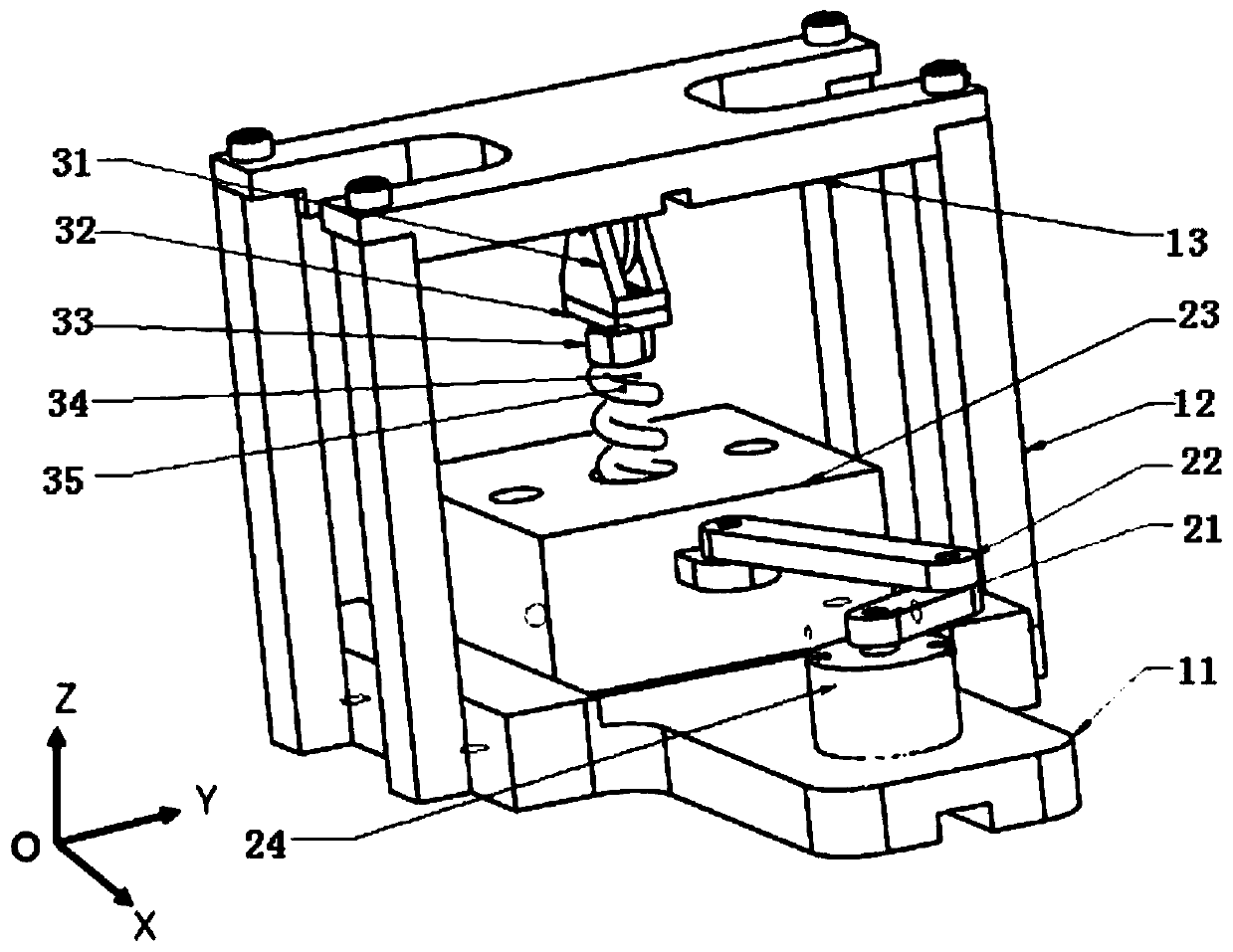

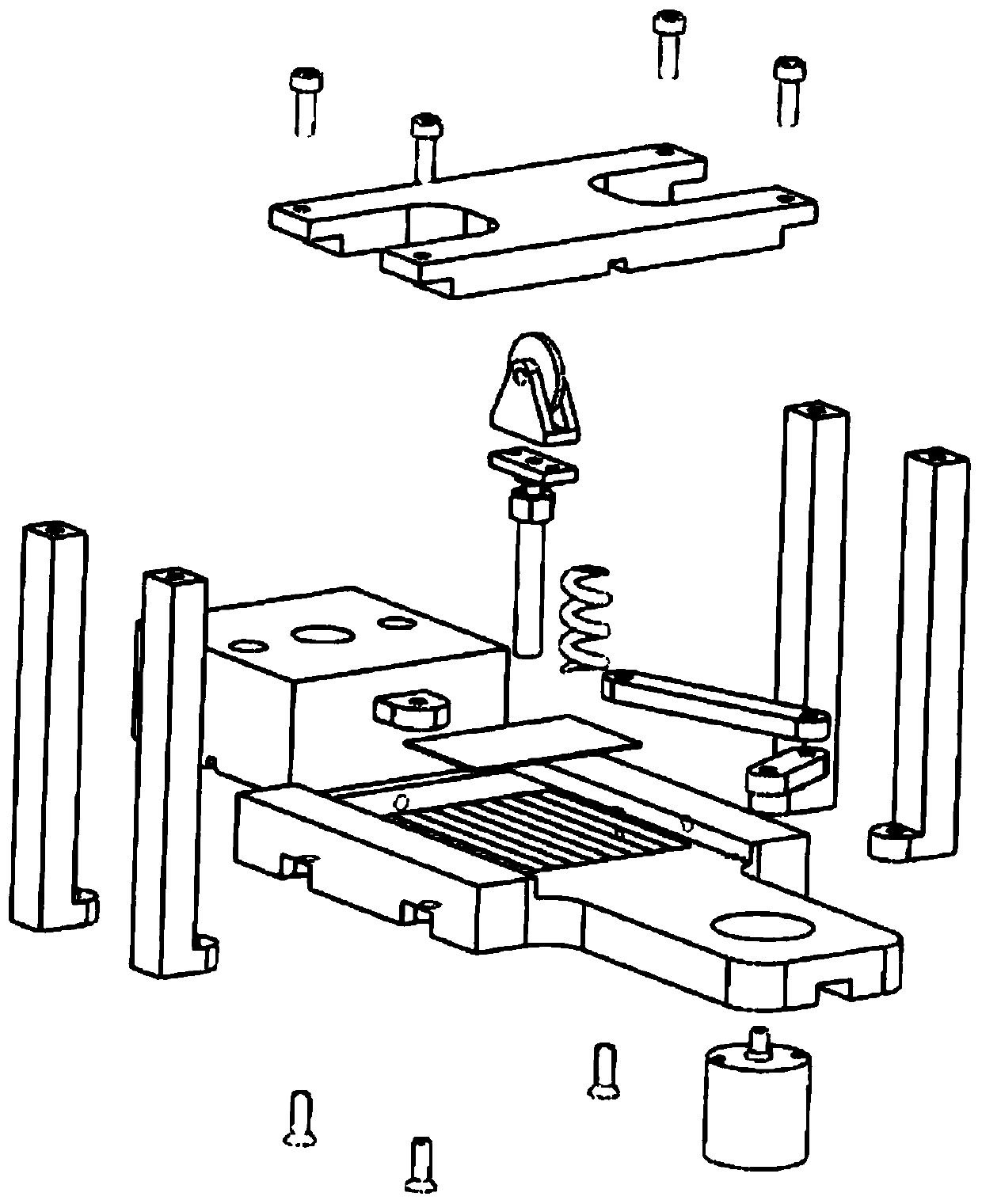

[0031] like Figure 1 to Figure 6 As shown, a device for directional roughening of the surface of an ionic polymer metal composite base film includes a frame 1, an actuator 2, a load 3 and a clamp 4, the frame 1 is a frame structure, and the frame 1 includes a base plate 11, Top plate 13 and several support beams 12, fixture 4 is installed on the bottom plate 11, and fixture 11 is used for fixing base film 5 to be processed, and load 3 is installed on the bottom of top plate 13, and actuator 2 is arranged between load 3 and fixture 4, The actuator 2 drives the load 3 to perform directional roughening treatment on the base film 5 along a preset path.

[0032] like figure 1 and Figure 5 As shown, the load 3 includes a fork wheel 31, the bottom of the fork wheel 31 is sequentially provided with a connecting block 32, an adjustment nut 33, a spring shaft 34 and a sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com