False boss for part numerical control machining

A technology of processing technology and bosses, which is applied in the field of CNC machining technology bosses of parts, can solve the problems of insufficient pressing force, increase of process and cost, and rotation of bosses, etc., to reduce displacement and rotation, and prevent bosses from being crushed Or the effect of scratching parts and increasing the radius of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

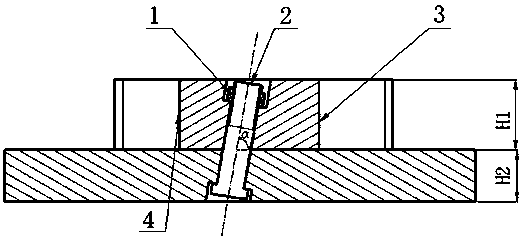

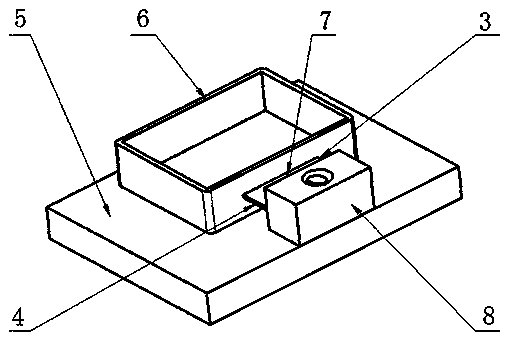

[0025] The present invention is realized through the following technical solutions, such as Figure 1-Figure 3 As shown, a part numerical control machining process boss is connected with part 6, including a boss 8 installed on tooling 5, a connecting edge 7 installed on boss 8 and arranged parallel to the side of tool 5 close to boss 8 And a compression bolt used to fix the boss 8 and the tooling 5; the boss 8 is provided with a compression screw hole, the tool 5 is provided with a stepped through hole communicating with the compression screw hole, the compression The tightening screw holes are sequentially stepped through holes and compression screw holes; the midline of the compression screw hole in the longitudinal direction forms an included angle α with the plane of the tool 5 on the side close to the boss 8, and the included angle α is less than 90 degrees, The longitudinal centerline of the stepped through hole is on the same straight line as the longitudinal centerline ...

Embodiment 2

[0029] This embodiment is further optimized on the basis of the above embodiment as figure 1 As shown, further, in order to better implement the present invention, the compression screw hole includes a small hole having the same diameter as the small end of the stepped through hole and communicating with the small end of the stepped through hole, and a large hole 9 connected to the end of the small hole away from the stepped through hole. ; The aperture of the small holes is smaller than the aperture of the large holes.

[0030] The stepped through hole includes a small hole A connected to the small hole, and a large hole A 11 arranged at one end of the small hole A away from the small hole. The hole diameter of the small hole A is the same as that of the small hole. The hole diameter is the same as that of the large hole 9. The A small hole and the small hole form a screw hole for installing a compression screw rod.

[0031] The other parts of this embodiment are the same as the ...

Embodiment 3

[0033] This embodiment is further optimized on the basis of the above embodiment, such as figure 1 As shown, further, in order to better implement the present invention, the height of the boss 8 is H1, and the height of the tooling 5 is H2, that is, the length of the tooling 5 along the longitudinal axis of the compression screw is H2, The length of the boss along the longitudinal axis of the compression screw is H1; the length of the screw 2 in the compression screw is L, L<(H1+H2) / sinα.

[0034] It should be noted that through the above improvement, the compression screw includes: nut 1 and screw 2, the compression screw is of standard shape, the length of the screw is L, and L should satisfy: L<(H1+H2) / sinα;

[0035] Preferably, L should satisfy: L<(H1+H2)*sinα;

[0036] The diameter of the compression screw is standard specifications: 12mm, 16mm, 25mm, and the length of the threaded area should ensure that there are threads within the height of the nut 1;

[0037] The other parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com