Independent adjustable combined electromagnetic braking device and method for controlling flowing of molten steel

An electromagnetic braking and adjustable technology, applied in the field of continuous casting, to achieve the effect of reducing impact, restraining impact and stabilizing the fluctuation of steel slag interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

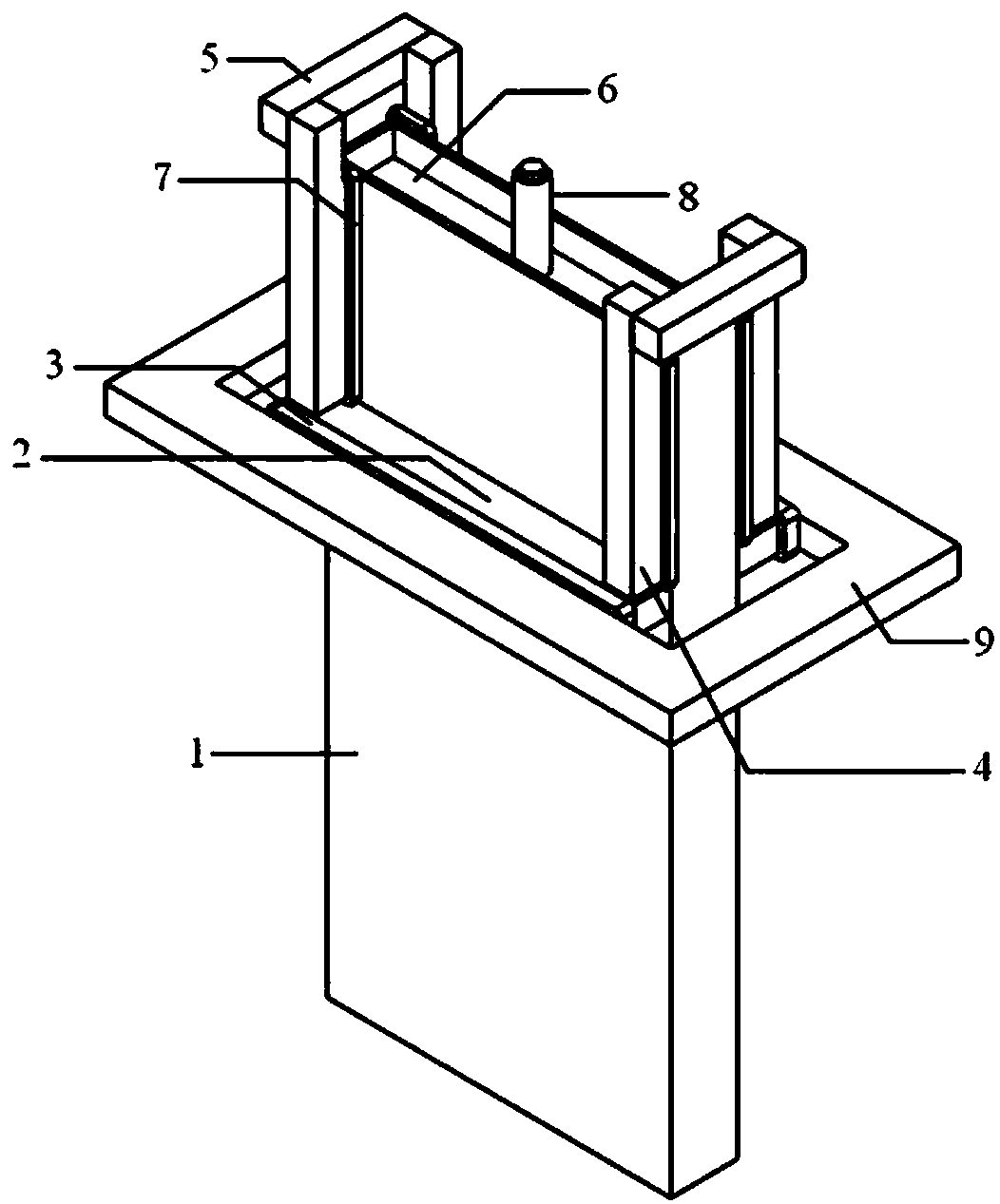

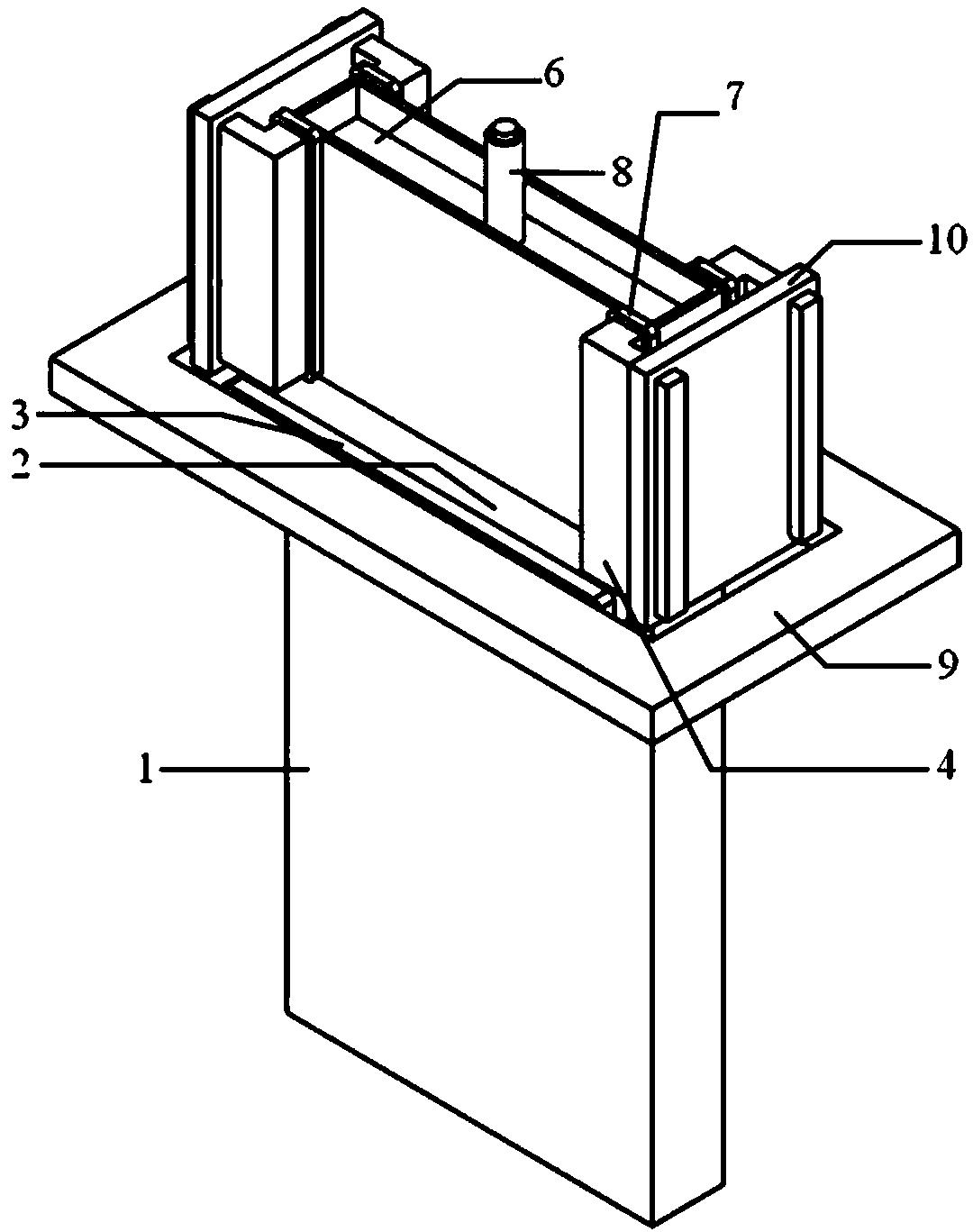

[0056] This implementation uses the image 3 In the shown independently adjustable combined electromagnetic braking device, in this embodiment, the vertical iron core 10 is set on the vertical magnetic pole 4, and the vertical magnetic pole 4 can move along the width direction of the crystallizer 1, and the horizontal magnetic pole 2 can move along the width direction of the crystallizer. 1 The thickness in the height direction is 150mm, the cross-sectional size of the crystallizer 1 is 1200mm×200mm, the height of the vertical magnetic pole 4 is 420mm, the electromagnetic braking DC power supply is 0-4000A, and the thickness center of the crystallizer 1 is changed under the current intensity The magnetic field distribution diagram along the height direction of the crystallizer 1.

[0057] An independently adjustable combined electromagnetic braking method for controlling the flow of molten steel, using an independently adjustable combined electromagnetic braking device for con...

Embodiment 2

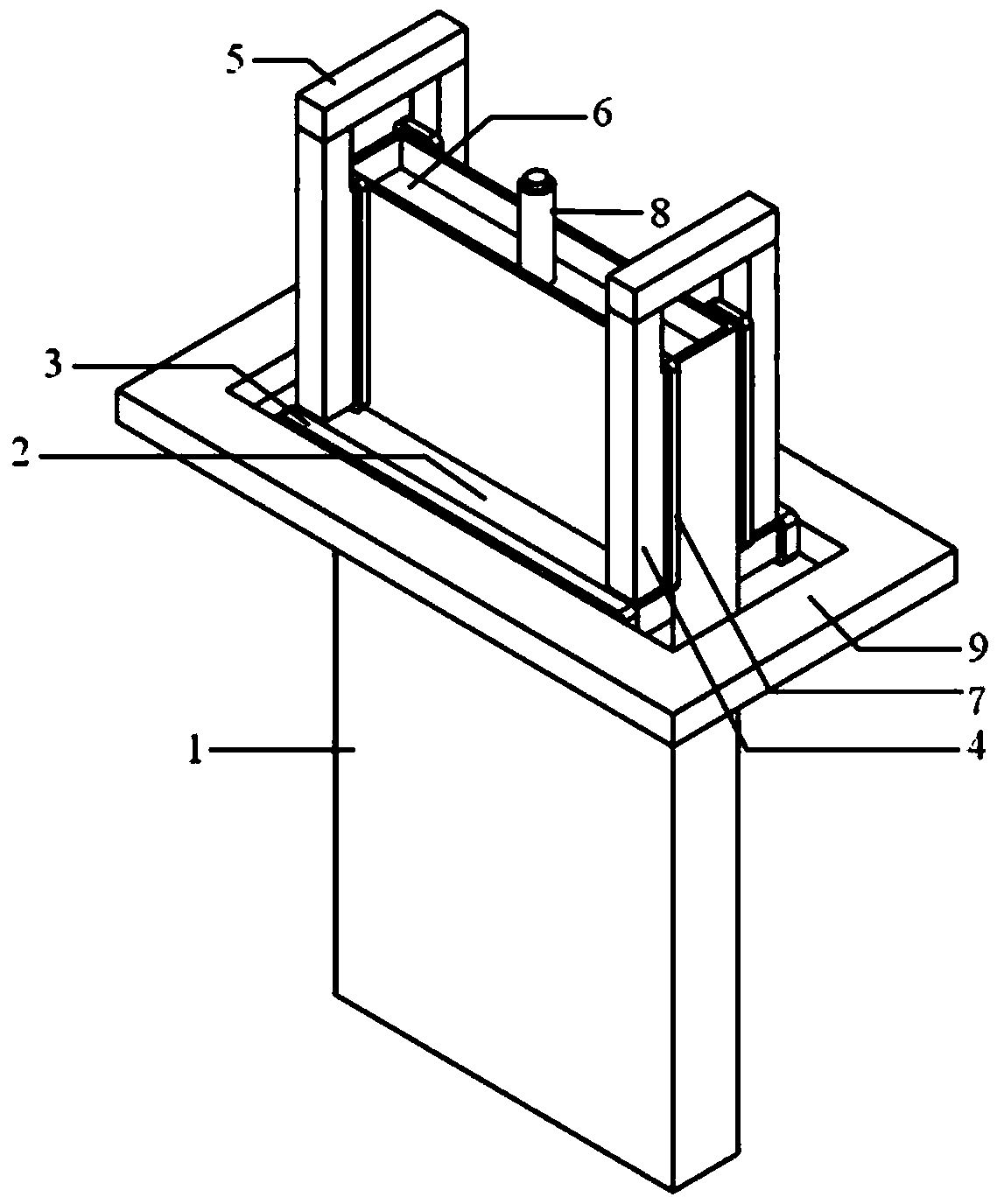

[0062] This embodiment adopts as image 3 In the shown independently adjustable combined electromagnetic braking device, in this embodiment, the vertical iron core 10 is set on the vertical magnetic pole 4, and the vertical magnetic pole 4 can move along the width direction of the crystallizer 1, and the horizontal magnetic pole 2 can move along the width direction of the crystallizer. 1 The thickness in the height direction is 150mm, the cross-sectional size of the crystallizer 1 is 1200mm×200mm, the height of the vertical magnetic pole 4 is 420mm, the inclination angle of the side hole of the submerged nozzle 8 is -15°, and the immersion depth of the submerged nozzle 8 is 210mm, the casting speed is 1.8m / min, the electromagnetic braking DC power supply is 0-4000A, and the flow field distribution of the molten steel at the center plane of the mold 1 thickness under the condition of with and without electromagnetic braking.

[0063] An independently adjustable combined electro...

Embodiment 3

[0068] This embodiment adopts as image 3 In the shown independently adjustable combined electromagnetic braking device, in this embodiment, the vertical iron core 10 is set on the vertical magnetic pole 4, and the vertical magnetic pole 4 can move along the width direction of the crystallizer 1, and the horizontal magnetic pole 2 can move along the width direction of the crystallizer. 1 The thickness in the height direction is 150mm, the cross-sectional size of the crystallizer 1 is 1200mm×200mm, the height of the vertical magnetic pole 4 is 420mm, the inclination angle of the side hole of the submerged nozzle 8 is -15°, and the immersion depth of the submerged nozzle 8 is 210mm, the billet casting speed is 1.8m / min, the electromagnetic braking DC power supply is 0-4000A, with or without electromagnetic braking and the flow velocity distribution diagram at 6 locations on the molten steel surface on the center surface of the thickness of the crystallizer 1 under changing DC pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com