Recyclable high-efficiency photocatalytic degradation material and preparation method thereof

A technology for degrading materials and photocatalysis, applied in the field of high-efficiency photocatalytic degradation materials and their preparation, can solve the problems of high density and easy sinking at the bottom of sewage, affecting the efficiency of photocatalytic degradation, and easily absorbing ultraviolet and visible light, and achieving good equipment versatility. , The effect of high utilization rate of raw materials and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A method for preparing a recyclable high-efficiency photocatalytic degradation material includes A: biomass bleaching, B: preparation of titanium dioxide nanoparticle suspension, C: surface treatment, specifically including:

[0020] A: Biomass bleaching

[0021] The biomass material with a moisture content lower than 25% is made into a biomass unit to be treated with a length of 1-50 cm, a width of 1-50 cm, and a thickness of 0.01-5 cm, and bleaching solution (0.1-10 mol / L) heated to 40°C~100°C, use bleaching solution to steam bleach or solution bleach the biomass unit for 0.2~48h to get the bleached biomass skeleton, then rinse with deionized water or ethanol for 3-5 times, at room temperature Dry and reserve;

[0022] B: Preparation of Titanium Dioxide Nanosuspension

[0023] Disperse titanium dioxide nanoparticles in water, sonicate for 5-20 minutes, let stand overnight, and take the upper titanium dioxide nanoparticle suspension solution for later use;

[0024]...

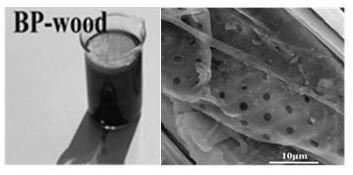

Embodiment 1

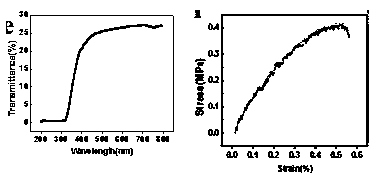

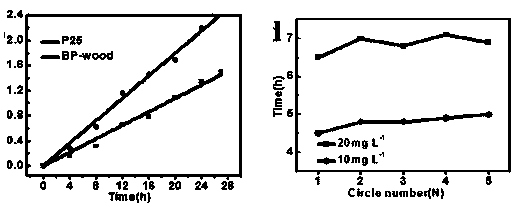

[0033] Process the linden wood with a moisture content of 10% to be processed into a wood sample of 5 cm x 5 cm x0.5 cm and place it on a plastic grid (aperture size: 0.5 cm, 2 cm from the liquid surface) in a glass beaker. The grid was placed above 30% hydrogen peroxide, and steamed at 100°C for 4 hours, then the wood-based composite material was taken out, rinsed three times with deionized water, and bleached wood was obtained. P25 was ultrasonically dispersed in deionized water, sonicated for 10 minutes, left to stand overnight, and the upper layer solution was taken to obtain a suspension solution of titanium dioxide nanoparticles with a concentration of 5 g / L, which was coated on the wood surface and dried at room temperature to obtain bleached wood / titanium dioxide Composite photocatalytic materials. The above-mentioned bleached wood / titanium dioxide composite photocatalytic material and the same amount of P25 suspension were respectively added to two parts of the same v...

Embodiment 2

[0037]Put the poplar leaves (size 10cm x 8cm x 0.05cm) with a moisture content of 5% to be treated on the stainless steel grid (aperture size: 3.0 cm) in the stainless steel container, and the stainless steel grid is immersed in 30% hydrogen peroxide at 95 °C for 6 hours, and then the bleached poplar leaves were taken out and washed with deionized water for 4 times to obtain the bleached poplar leaves. P25 was ultrasonically dispersed in deionized water for 5 minutes, left standing overnight, and the upper layer solution was taken to obtain a suspension solution of titanium dioxide nanoparticles with a concentration of 10 g / L, which was coated on the surface of bleached poplar leaves, and dried at room temperature to obtain bleached poplar leaves / Nano titanium dioxide composite photocatalytic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com