Preparation method of ruthenium cobalt magnetic catalyst and application thereof in selective hydrogenation

A magnetic catalyst and neutral technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as increased investment costs, dangerous operating environment, non-compliance, etc., and achieve low-carbon industry The effects of production, risk reduction, and ease of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

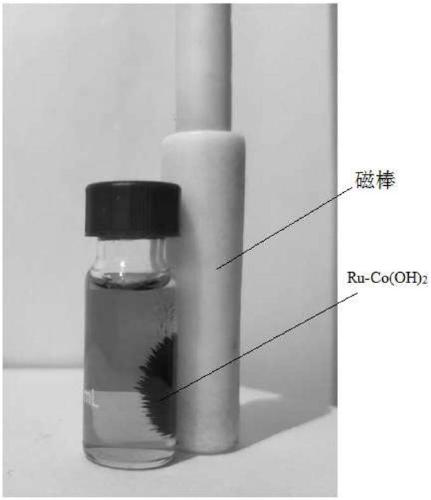

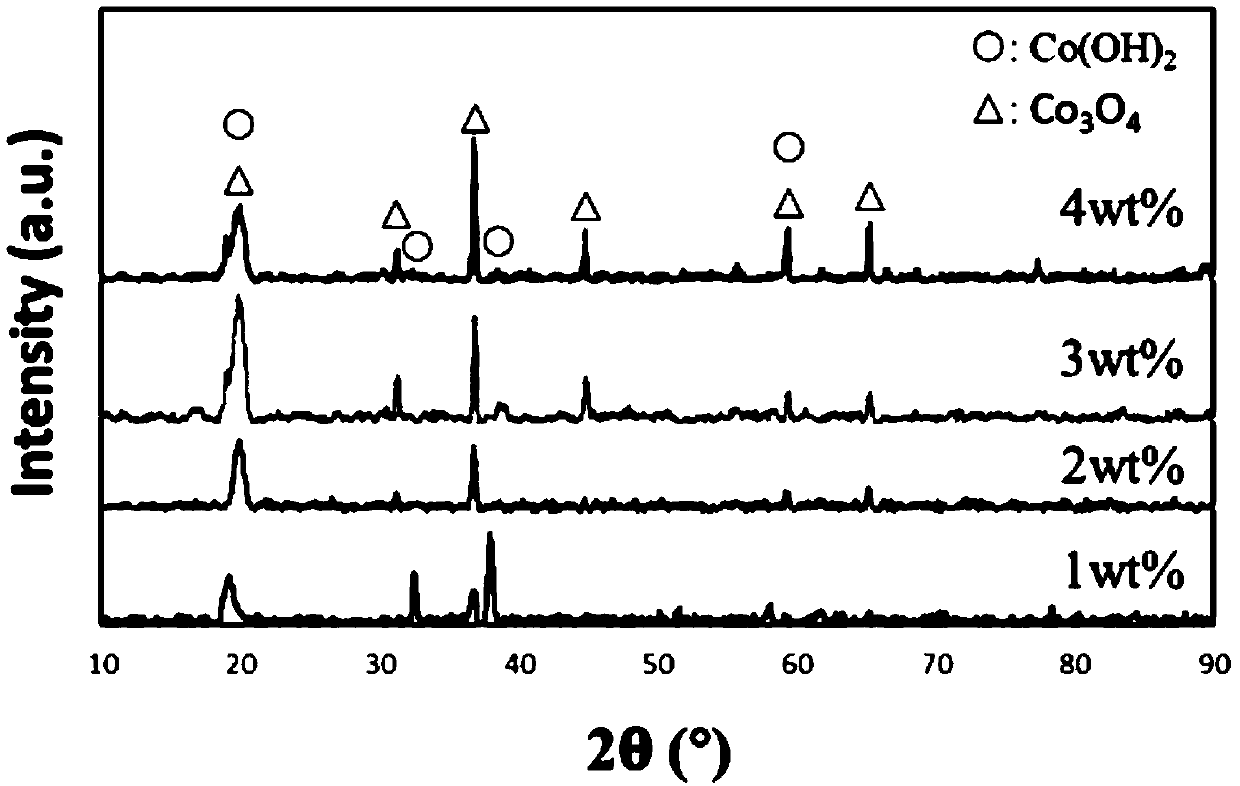

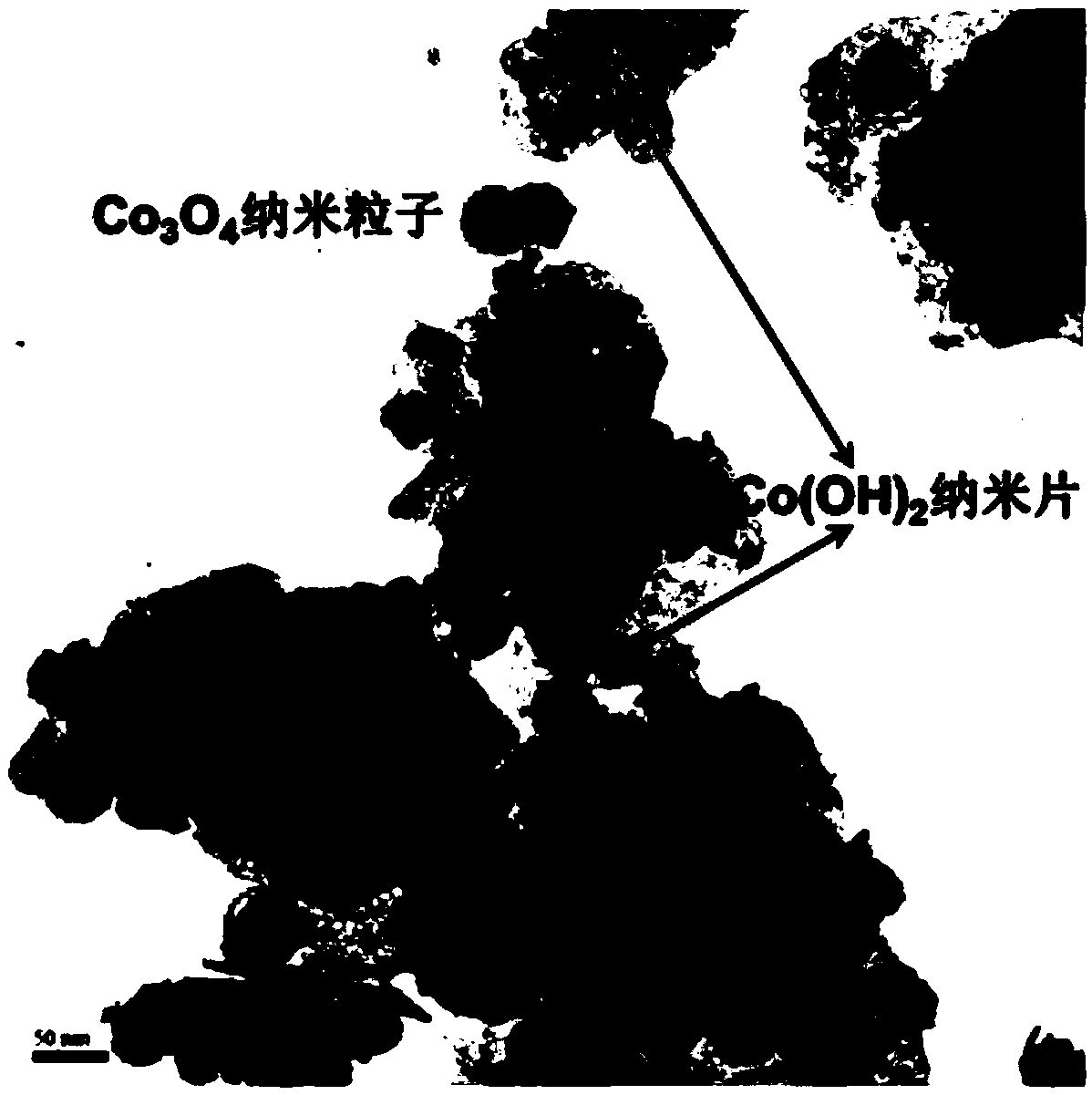

[0041] Ru-Co(OH) with different Ru loadings 2 The preparation method of catalyst, comprises the steps:

[0042] S1. Weigh 0.94gCo(NO 3 ) 2 ·6H 2 O was dissolved in 750ml of water, and prepared into solution a under mechanical stirring, and the stirring rate was 350rpm;

[0043] S2. prepare 0.00482g / ml chlororuthenic acid aqueous solution, pipette a certain amount of 0.00482g / ml chlororuthenic acid solution Specifically, when the Ru load is 1wt%, pipette 0.63ml 0.00482g / ml chlororuthenic acid solution; when the Ru load is 2wt%, pipette the ruthenium chloride solution of 1.25ml 0.00482g / ml; when the Ru load is 3wt%, pipette the ruthenium chloride solution of 1.87ml 0.00482g / ml; At 4wt%, pipette 2.49ml of 0.00482g / ml chlororuthenic acid solution, then add the pipetted chlororuthenic acid solution dropwise into solution a to prepare solution b;

[0044] S3. prepare polyvinylpyrrolidone solution, that is, polyvinylpyrrolidone solution is dissolved in 25ml water by 345.20mg pol...

Embodiment 2

[0057] Ru-Co(OH) with 3wt% Ru loading under different reduction methods 2 The preparation method of catalyst, comprises the steps:

[0058] S1. Weigh 0.94gCo(NO 3 ) 2 ·6H 2 O was dissolved in 750ml of water, and prepared into solution a under mechanical stirring, and the stirring rate was 350rpm;

[0059] S2. prepare the chlororuthenic acid aqueous solution of 0.00482g / ml, pipette the chlororuthenic acid solution of 1.87ml0.00482g / ml, and add dropwise in the solution a, make the solution b;

[0060] S3. prepare polyvinylpyrrolidone solution, that is, polyvinylpyrrolidone solution is dissolved in 25ml water by 345.20mg polyvinylpyrrolidone and stirred; then the prepared polyvinylpyrrolidone solution is Add solution b dropwise under stirring condition, and keep stirring for 15min to obtain solution c;

[0061] S4. Prepare sodium borohydride solution, namely sodium borohydride solution is dissolved in 160ml water by 644.60mg sodium borohydride, stirred, and the prepared sodi...

Embodiment 3

[0073] Different H 2 Ru-Co(OH) with 3 wt% Ru loading at reduction temperature 2 The preparation method of catalyst, comprises the steps:

[0074] S1. Weigh 0.94gCo(NO 3 ) 2 ·6H 2 O was dissolved in 750ml of water, and prepared into solution a under mechanical stirring, and the stirring rate was 350rpm;

[0075] S2. prepare the chlororuthenic acid aqueous solution of 0.00482g / ml, pipette the chlororuthenic acid solution of 1.87ml0.00482g / ml, and add dropwise in the solution a, make the solution b;

[0076] S3. prepare polyvinylpyrrolidone solution, that is, polyvinylpyrrolidone solution is dissolved in 25ml water by 345.20mg polyvinylpyrrolidone and stirred; then the prepared polyvinylpyrrolidone solution is Add solution b dropwise under stirring condition, and keep stirring for 15min to obtain solution c;

[0077] S4. Prepare sodium borohydride solution, namely sodium borohydride solution is dissolved in 160ml water by 644.60mg sodium borohydride, stirred, and the prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com