Photocatalytic net for water purification and its preparation and application

A technology for purifying water quality and catalytic net, applied in physical/chemical process catalysts, chemical instruments and methods, special compound water treatment, etc., can solve the problems of shedding, high energy consumption and cost, unstable material, etc. wear resistance, uniform loading and firmness, and the effect of improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

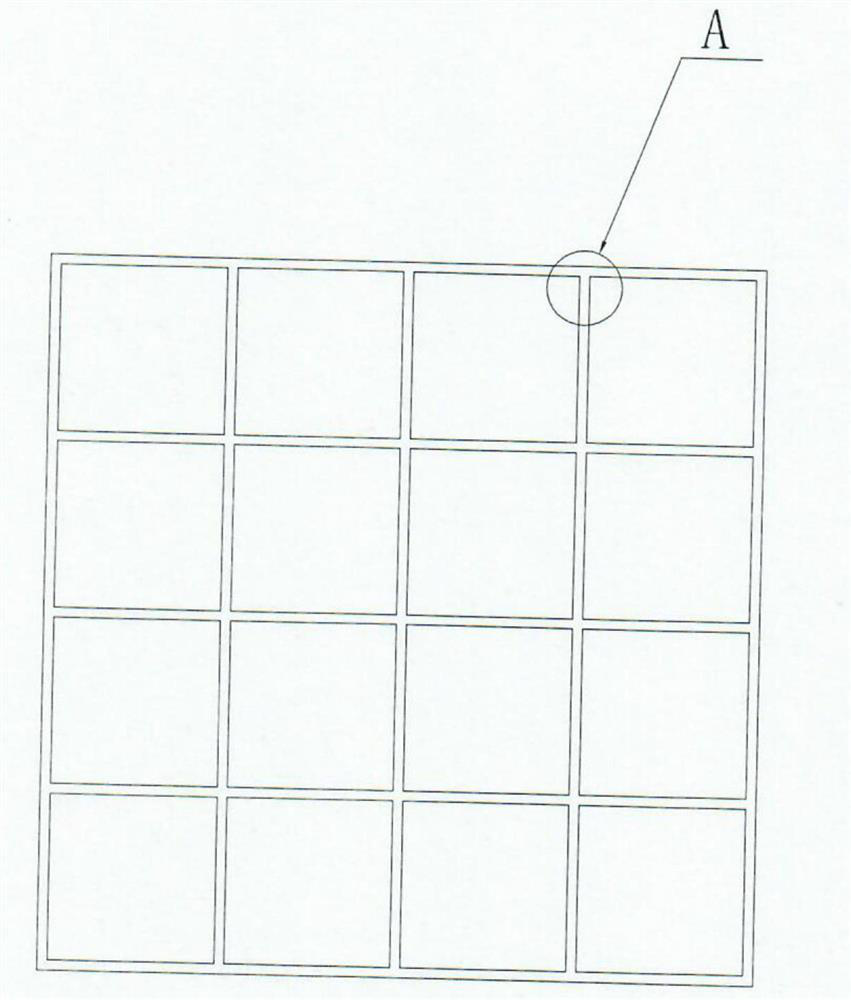

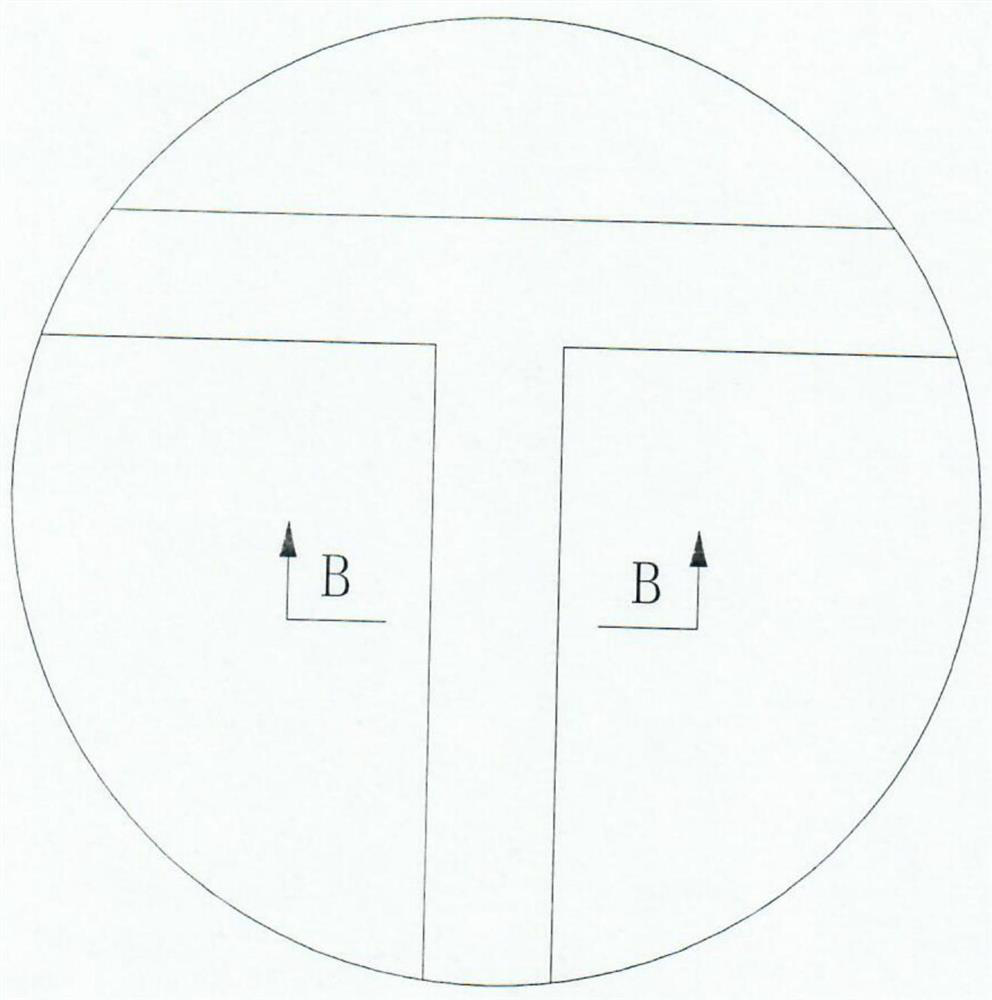

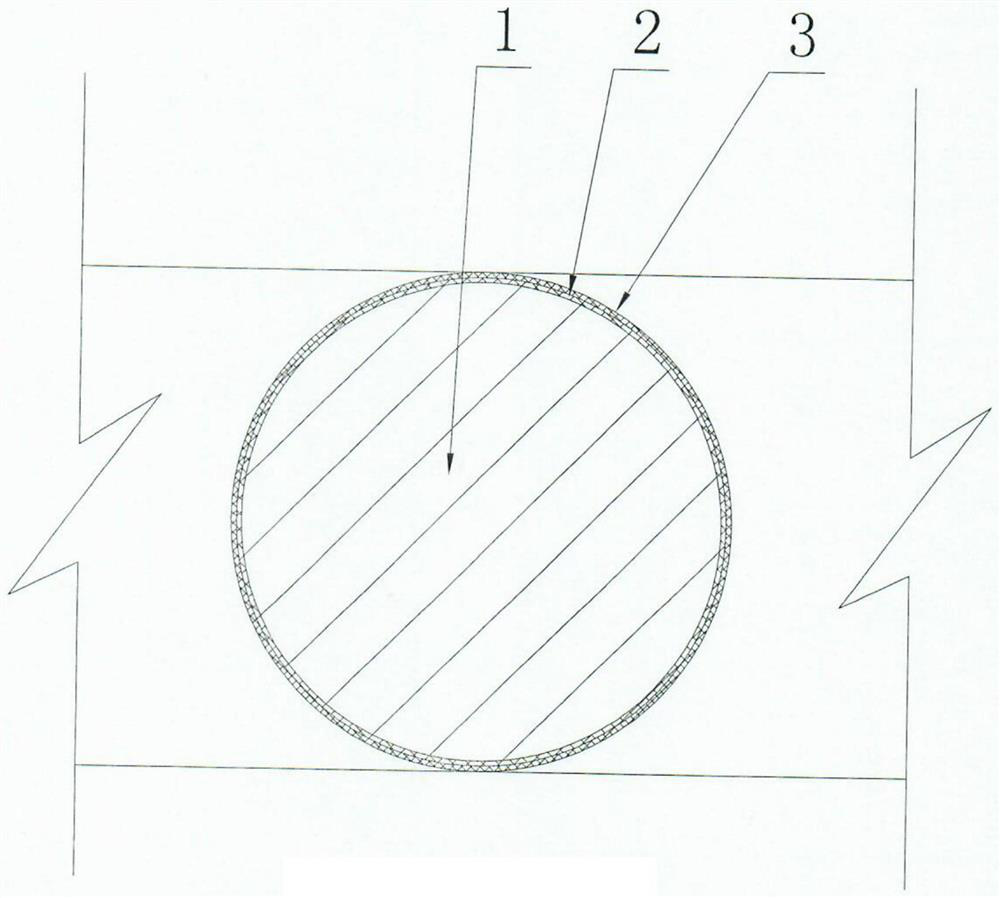

[0044] The photocatalytic net for water purification consists of a net plate 1 made of metal aluminum or aluminum alloy, an oxide film layer 2 evenly distributed on the surface of the net plate 1, and a photocatalyst coating 3 attached to the outer surface of the oxide film layer 2.

[0045] A method for preparing a photocatalytic net for purifying water, comprising the following process steps:

[0046] A. Pretreatment of stencil

[0047] Remove the oil stains and attachments on the surface of aluminum or aluminum alloy mesh panels;

[0048] B. Oxidation treatment

[0049] Adopting the anodic oxidation method to make an oxide film with a thickness of 10-50 microns on the surface of the stencil that is degreased in step A;

[0050] C. The surface of the substrate is clean;

[0051] D. Adopt the method of vacuum evaporation to carry out photocatalyst loading on the substrate

[0052] The coating material is mixed into an emulsion with a coupling agent, and the coating materi...

Embodiment 2

[0066] The difference between this embodiment and embodiment 1 is:

[0067] A method for preparing a photocatalytic net for purifying water, comprising the following process steps:

[0068] A. Pretreatment of stencil

[0069] Remove the oil stains and attachments on the surface of aluminum or aluminum alloy mesh panels;

[0070] B. Oxidation treatment

[0071] Adopting the anodic oxidation method to make an oxide film with a thickness of 10-50 microns on the surface of the stencil that is degreased in step A;

[0072] C. The surface of the substrate is clean;

[0073] D. Adopt the method of vacuum evaporation to carry out photocatalyst loading on the substrate

[0074] The coating material is mixed into an emulsion with a coupling agent, and the coating material is Ti 2 o 3 , the coupling agent is a titanate coupling agent or a silane coupling agent, the mass ratio of the coupling agent to the coating material=3:1; the coating chamber is evacuated to a pressure of 0.01Pa...

Embodiment 3

[0083] The difference between this embodiment and embodiment 1 is:

[0084] A method for preparing a photocatalytic net for purifying water, comprising the following process steps:

[0085] A. Pretreatment of stencil

[0086] Remove the oil stains and attachments on the surface of aluminum or aluminum alloy mesh panels;

[0087] B. Oxidation treatment

[0088] Adopting the micro-arc oxidation method to make an oxide film with a thickness of 10-50 microns on the surface of the stencil that is degreased in step A;

[0089] C. The surface of the substrate is clean;

[0090] D. Adopt the method of vacuum evaporation to carry out photocatalyst loading on the substrate

[0091] The coating material is mixed into an emulsion with a coupling agent, and the coating material is Ti3 o 5 , the coupling agent is a silane coupling agent, the mass ratio of the coupling agent to the coating material = 2:1; the coating chamber is evacuated to a pressure of 0.01Pa, and the emulsion is elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com