An assembled steel concrete composite beam and a forming method thereof

A technology of concrete and composite beams, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., which can solve problems such as easy cracking, and achieve the effects of saving costs, firm connections, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

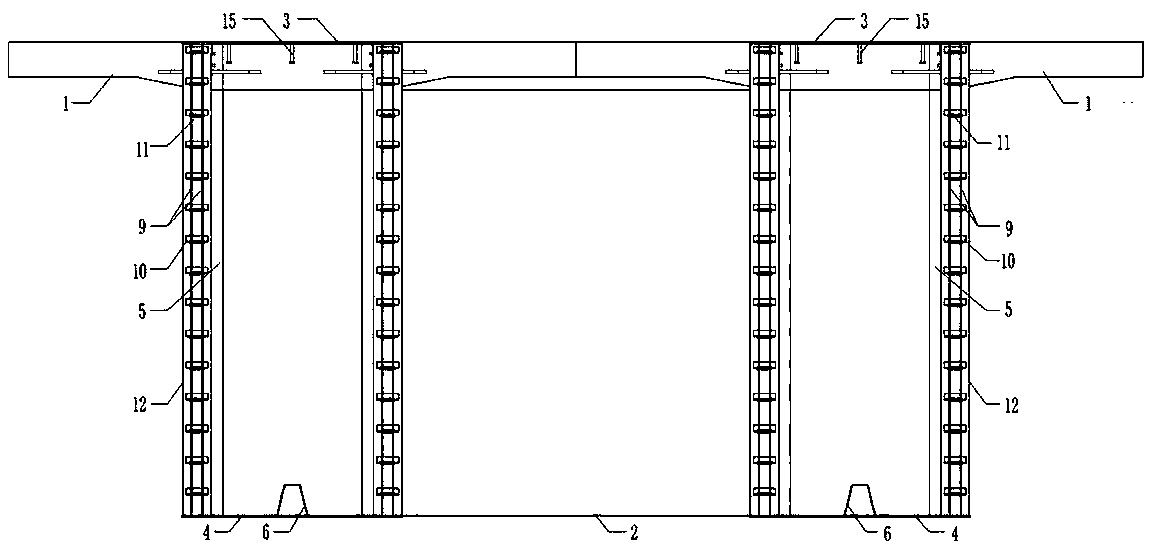

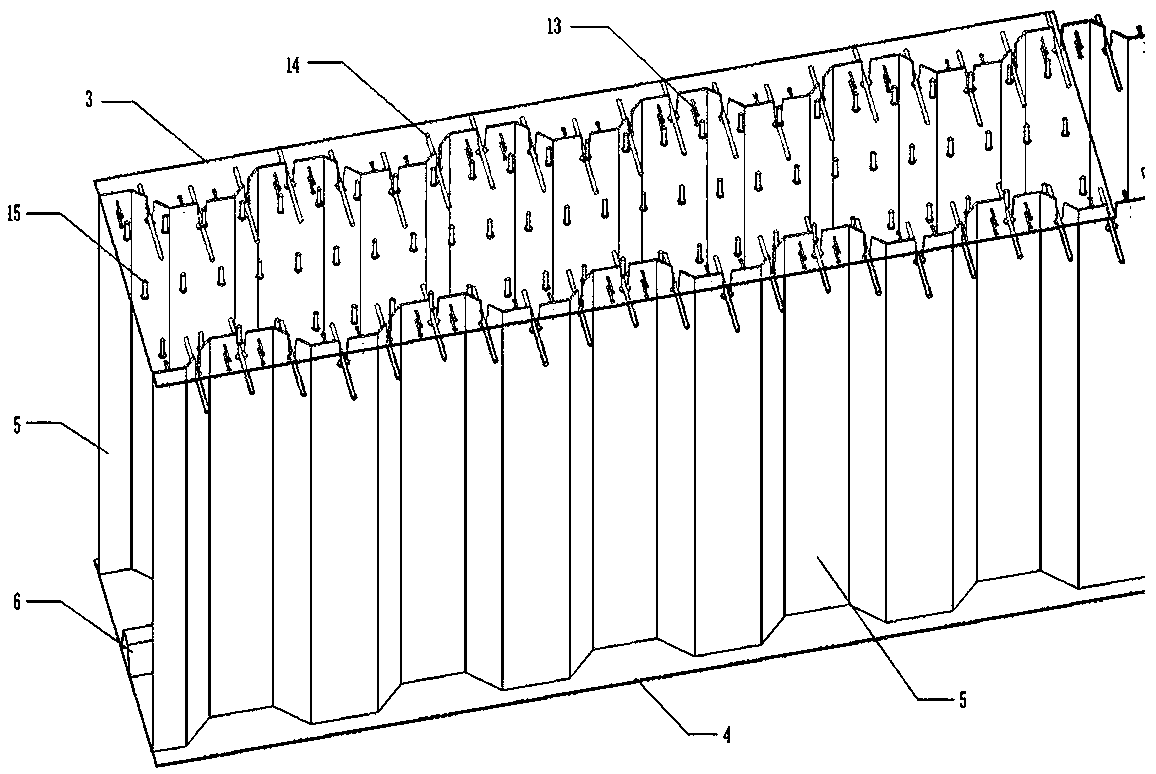

[0037] The specific embodiment one of the assembled steel-concrete composite beam of the present invention, such as figure 1 As shown, the assembled steel-concrete composite beam includes a steel box beam and a concrete panel 1, the steel box beam constitutes a supporting beam, the steel box beam includes a steel box beam body and an upper flange roof 3, the steel box beam body is U-shaped, and the concrete The face plate 1 is poured on the lower end of the upper flange roof plate 3 to ensure that the upper flange roof plate 3 and the concrete face plate 1 are poured densely and the connection is firm. There are shear nails 15. The shear nails 15 constitute a shear connector. The shear nails 15 can resist the horizontal shear force on the negative bending moment and ensure the stability of the composite beam; the two sides of the steel box girder are cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com