Combined sandwich type heat preservation layer structure

A combined, sandwich-type technology, applied in the direction of thermal insulation, building structure, building components, etc., can solve the problems of loose connection, low production efficiency, and high production conditions in the sandwich composite process, and is conducive to popularization, use and production. The effect of cost reduction and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described in detail in conjunction with the following drawings.

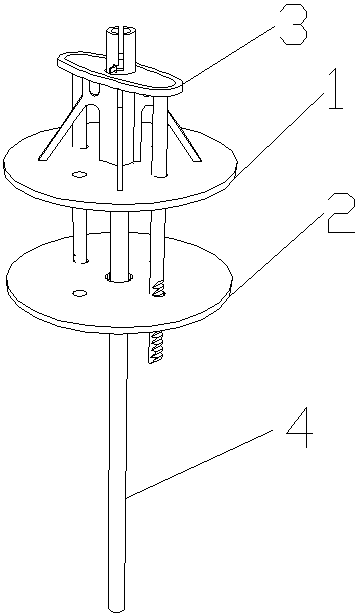

[0035] Such as figure 1 , Figure 10 , Figure 11 As shown, a combined sandwich type insulation layer structure includes a heat preservation board 6, a steel wire mesh sheet 5, and a combined sandwich piece.

[0036] The combined sandwich piece includes an upper plate 1 of the push-stop piece, a lower plate 2 of the push-stop piece, a double-rod piercing nail 3 and a connecting rod 4 .

[0037] Both the upper plate 1 and the lower plate 2 of the anti-push plate are provided with perforations corresponding to the positions, and the double-rod nails 3 and the connecting rods 4 pass through the perforations to clamp the insulation board 6 on the upper plate 1 of the anti-push plate and the anti-push plate Between the bottom plate 2.

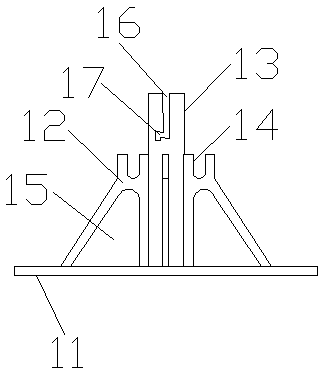

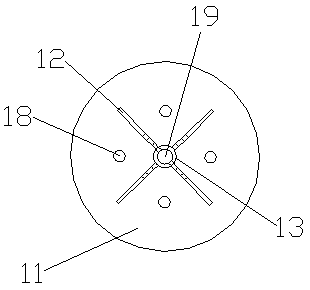

[0038] The push-stop plate upper plate 1 is provided with a mesh card slot 14, and the mesh card slot 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com