Treatment device for building wastes

A technology for processing equipment and construction waste, which is applied in grain processing, combined equipment, and smoke and dust removal. The effect of suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

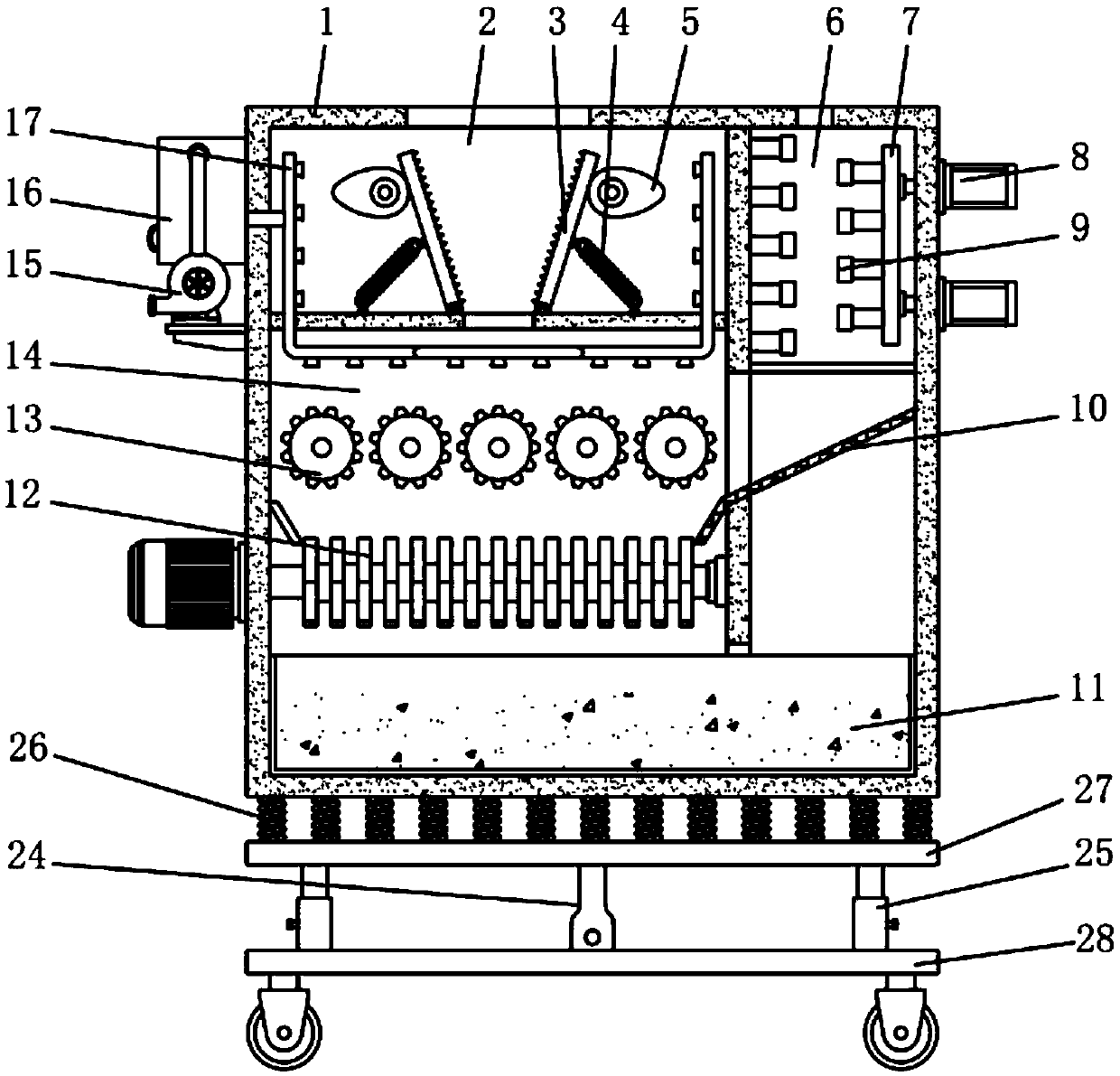

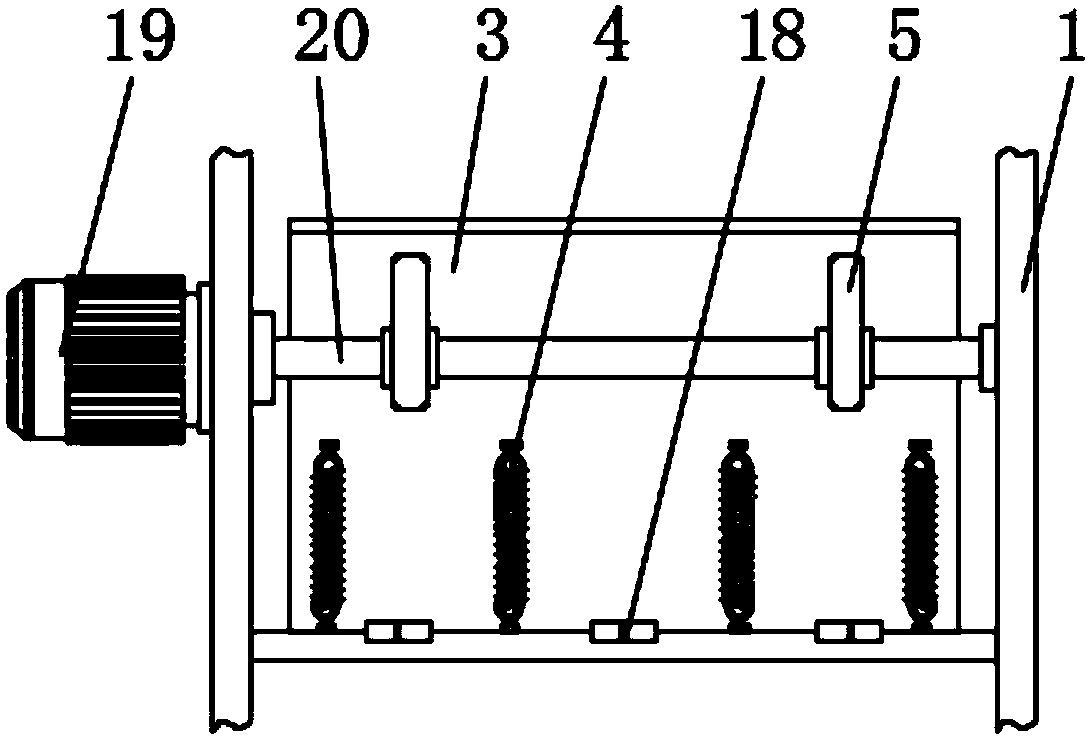

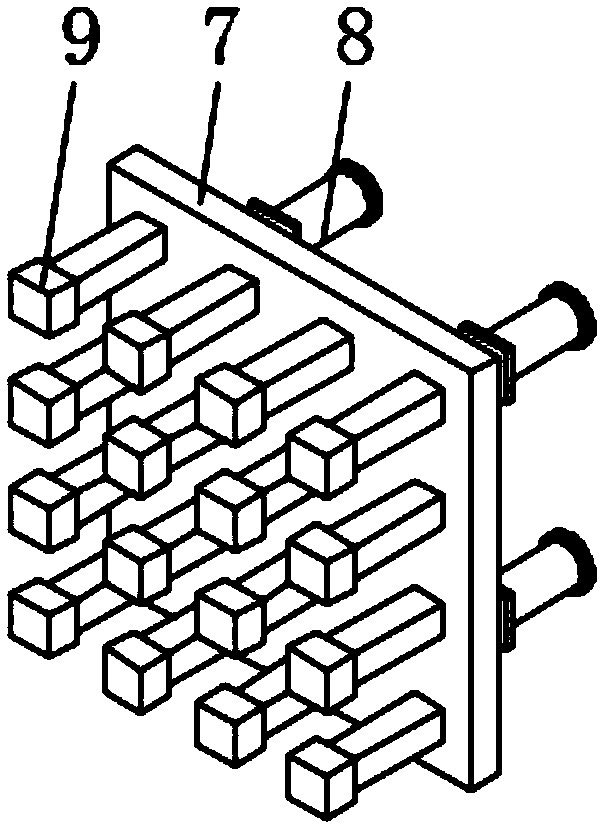

[0030] see Figure 1-2 , a construction waste processing device, including a device body 1, a first crushing chamber 2 and a second crushing chamber 6 are respectively arranged on the top of the device body 1 from left to right, and the first crushing chamber 2 is located inside the device body 1 There is a third crushing chamber 14, and the inner bottom plate of the first crushing chamber 2 is connected to the extruding jaw plate 3 through the hinge shaft 18, and the surface of one side of the extruding jaw plate 3 is in contact with the cam 5, and there is a cam 5 below the cam 5. The tension spring 4 connecting the bottom plate and the extrusion jaw plate 3, the cam 5 is installed on the surface of the drive shaft 20, and one end of the drive shaft 20 extends to the surface of the device body 1. A motor 19 is fixed on the surface, and a motor 19 is installed on the bottom of the third crushing chamber 14. The three-stage crushing roll 12, and the top of the three-stage crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com