Preparation of MoSe2/SrTiO3 efficient compound photocatalyst

A technology of photocatalyst and composite light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. It can solve problems such as complex steps, and achieve the effects of easy control of conditions, good stability, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] SrTiO 3 Preparation: Weigh 1.26g of citric acid and dissolve it in 15mL of absolute ethanol, quickly inject 1.5mL of isopropyl titanate with a pipette gun, keep stirring, add dropwise 1.06g of strontium nitrate solution and 2g of sodium hydroxide solution, and keep stirring After 30 minutes, the mixed solution was poured into a polytetrafluoroethylene-lined hydrothermal kettle, and reacted at 150°C for 36 hours. When cooled to room temperature, wash with deionized water, acetic acid and ethanol respectively, and dry at 80°C for 24h.

[0024] MoSe 2 / SrTiO 3 Preparation of photocatalyst: Weigh 0.05g sodium molybdate, 0.01g selenium powder and 0.24g sodium borohydride, 1g of SrTiO 3 , dissolved in 30mL distilled water and 30mL ethanol, continuously stirred for 30min, poured the mixed solution into a hydrothermal kettle containing p-polyphenol liner, and reacted for 24h at 240°C. When cooled to room temperature, wash with deionized water and ethanol respectively, and d...

Embodiment 2

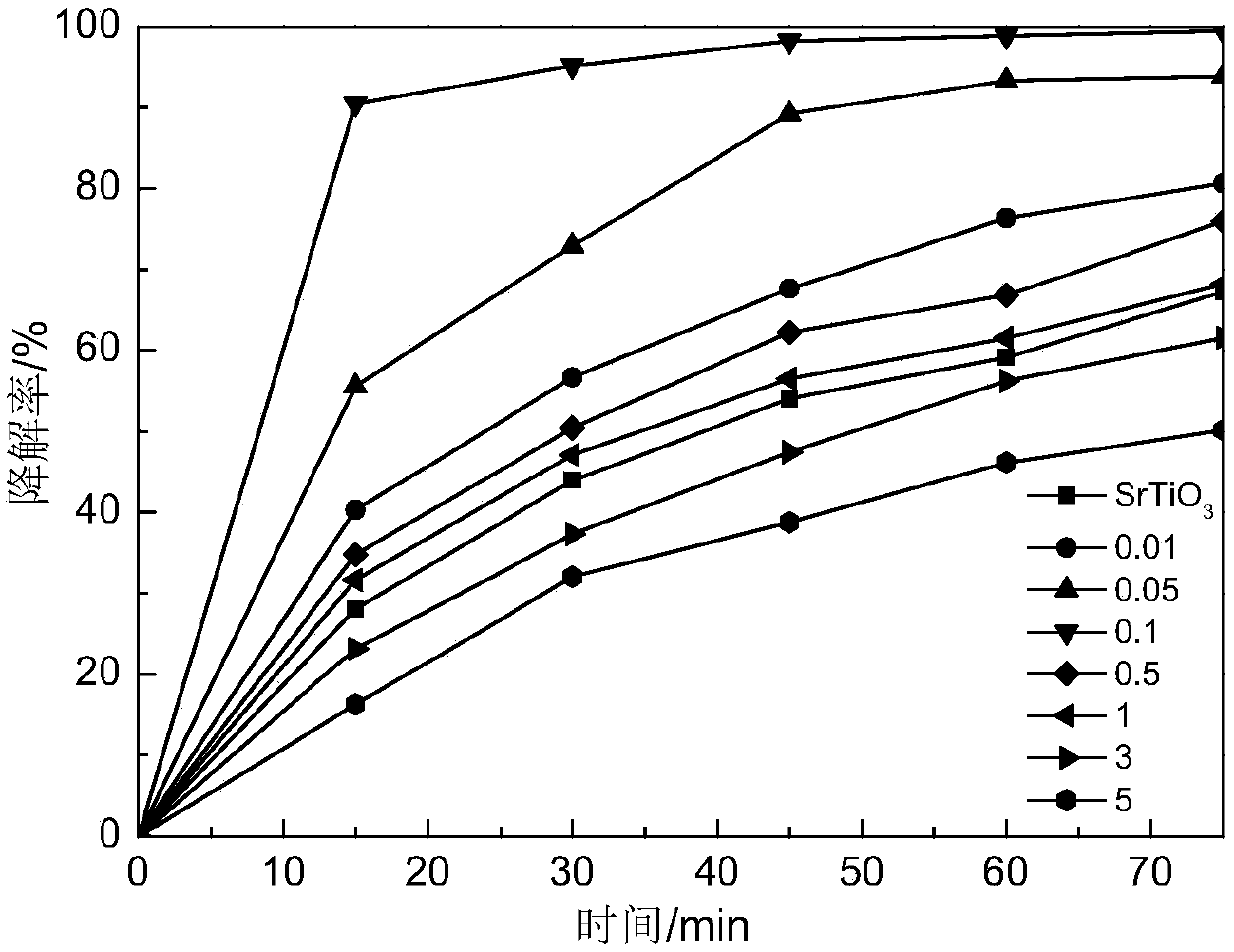

[0026] Composite MoSe with different components can be obtained only by changing the quality of sodium molybdate and selenium powder under other conditions. 2 SrTiO 3 Catalyst, respectively 0.01% MoSe 2 / SrTiO 3 , 0.05% MoSe 2 / SrTiO 3 , 0.1% MoSe 2 / SrTiO 3 , 0.5% MoSe 2 / SrTiO 3 , 1% MoSe 2 / SrTiO 3 and 5% MoSe 2 / SrTiO 3 .

[0027] MoSe 2 / SrTiO 3 Photocatalytic degradation of methyl orange: 0.2 g of 3% MoSe 2 / SrTiO 3 Adding concentration is 20mg·L -1 500mL of methyl orange solution, ultrasonic 30min, in the photocatalytic reactor, turn on the magnetic stirring, shield all light sources, and carry out dark adsorption for 30min. First measure 4mL of the mixed solution that has reached adsorption equilibrium as the first sample, and mark it as C 0 , Then turn on the mercury lamp, take 4mL solution samples every 15min, and mark it as C. Each sample was centrifuged at high speed, and the supernatant was taken to measure its absorbance.

[0028] Calculate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com