A kind of preparation method of composite material catalyst, its product and application

A technology of composite materials and catalysts, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve problems such as shedding, catalyst deactivation, etc., to reduce the difficulty of forming and manufacturing, large specific surface area , the effect of a reasonable liquid flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

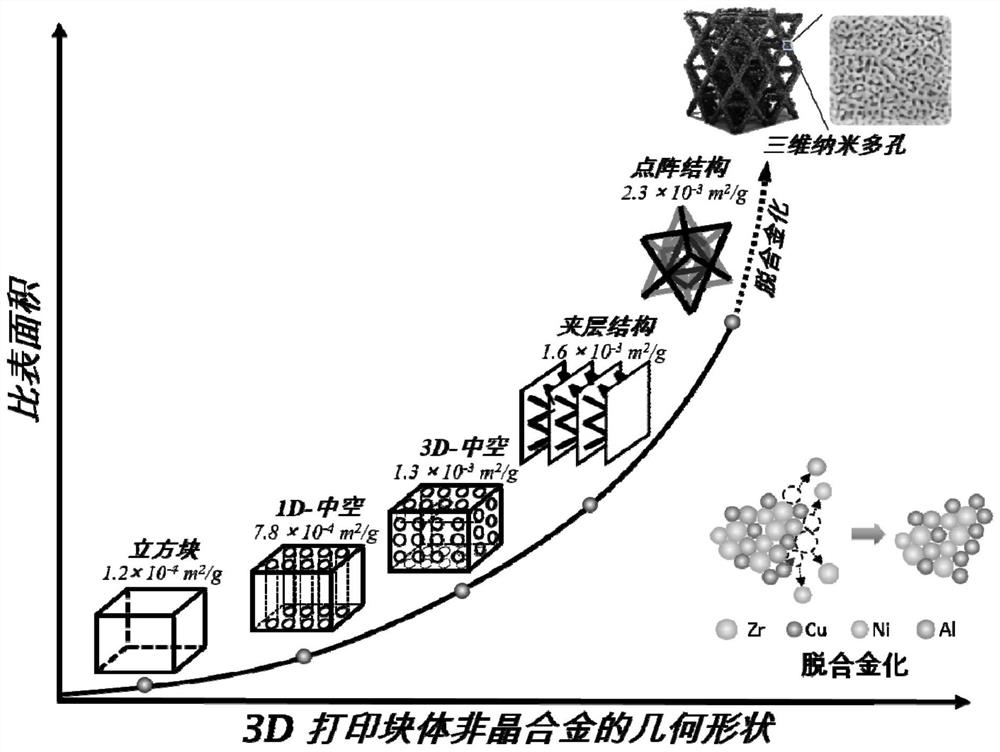

[0035] The invention provides a kind of preparation method of composite material catalyst, it comprises the steps:

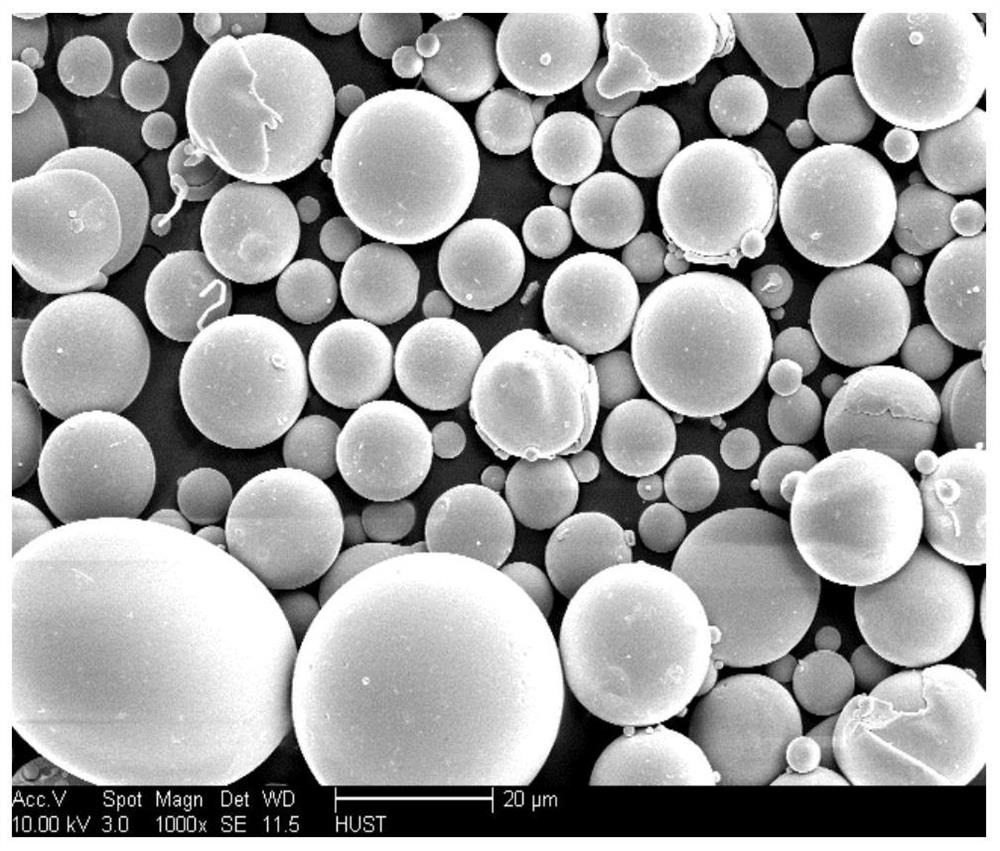

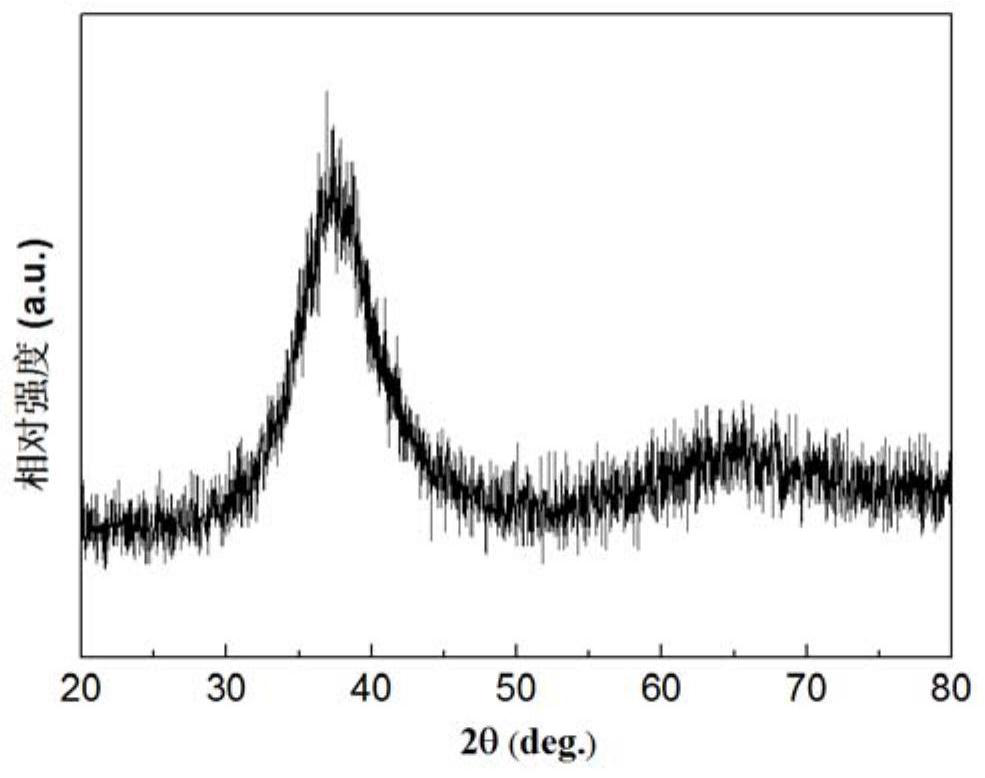

[0036] S1: Preparation of nano / microporous amorphous alloy precursors by 3D printing;

[0037] S2: Selectively corrode nano / microporous amorphous alloy precursors with chemical or electrochemical processes through corrosive liquids, prepare metal nanoporous structures on the surface of the precursors, and obtain hierarchical porous structures;

[0038] S3: Perform surface modification on the hierarchical porous structure to form metal oxides or metal sulfides, so as to improve the catalytic performance of the hierarchical porous structure, and perform surface modification in one or more of the following ways:

[0039] i. Heating oxidation under oxygen atmosphere;

[0040] ii. Anodizing in lye;

[0041] iii. Electrostatic adsorption of nanoscale oxides;

[0042] iv. Vulcanization in polysulfides;

[0043] v. Electrochemical deposition.

[0044] In actual eng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com