A kind of formaldehyde scavenger and preparation method thereof

A formaldehyde scavenger and compound technology, applied in the field of air purification, can solve the problems of insufficient speed of decomposition of formaldehyde, high cost of preparation and raw materials, and great influence of photocatalyst light conditions, etc., to achieve strong formaldehyde degradation ability and mild application conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

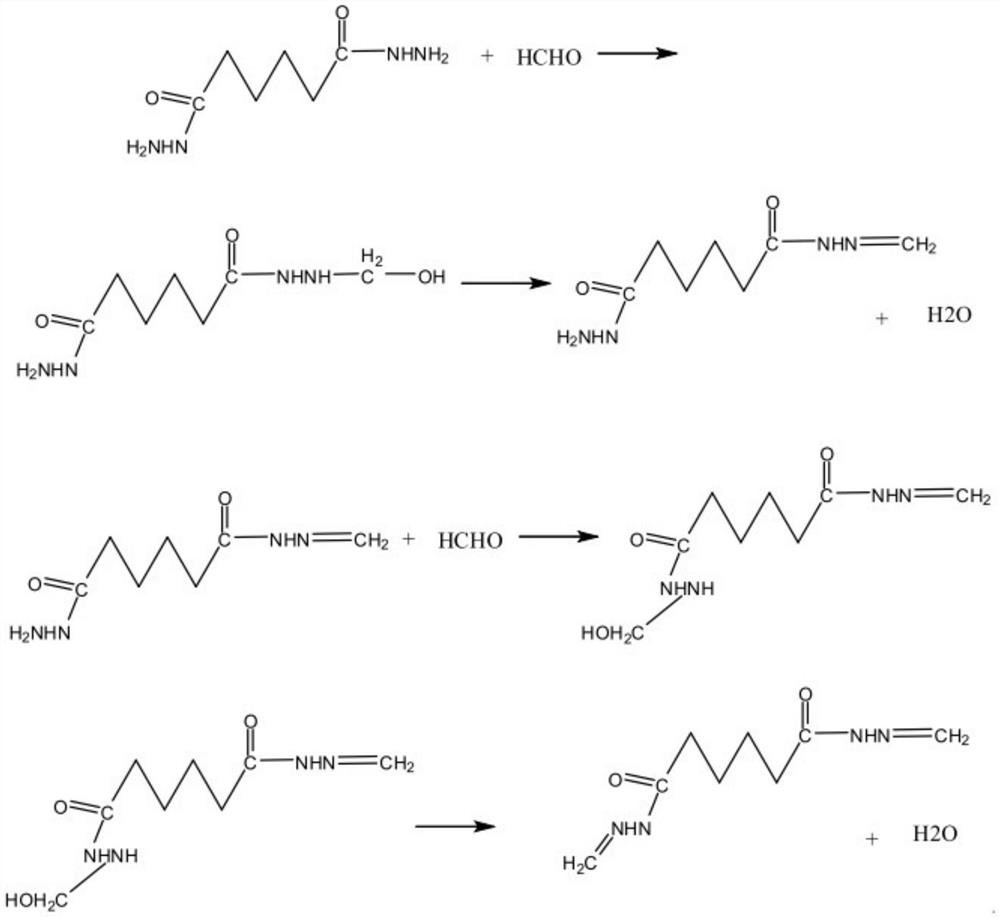

Method used

Image

Examples

preparation example Construction

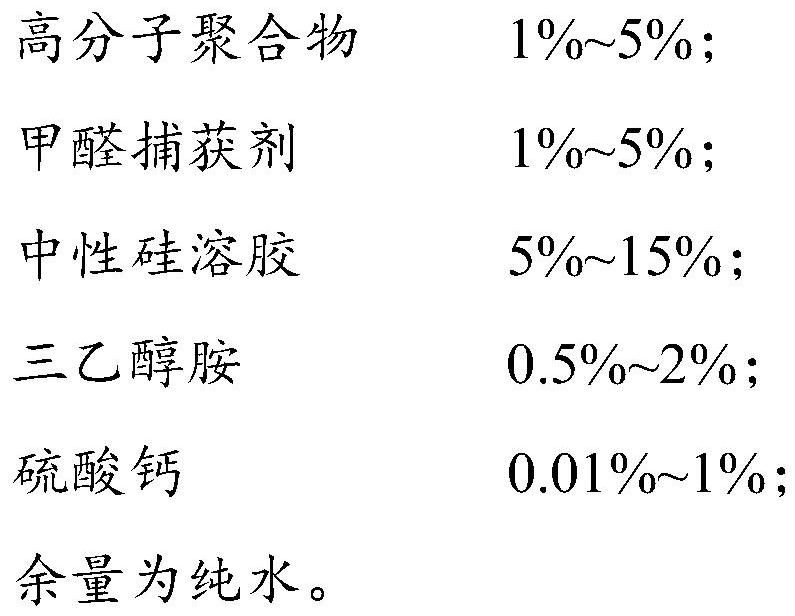

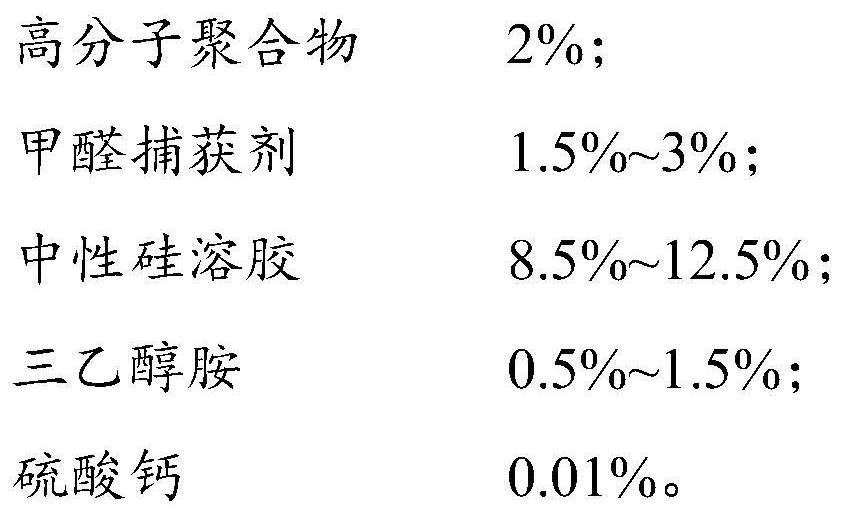

[0035] The embodiment of the present invention also relates to a preparation method of a formaldehyde scavenger, comprising the following steps: adding formaldehyde trapping agent and neutral silica sol into pure water, stirring evenly, adding triethanolamine and calcium sulfate, finally adding high molecular polymer, stirring evenly Then get the formaldehyde scavenger.

[0036] In a specific embodiment of the present invention, the preparation method of the formaldehyde scavenger comprises the following steps: take 1 / 2 volume of pure water, heat it to 28-30° C., and add the formulated amount of formaldehyde scavenger. After stirring for 20 to 30 minutes, add the formula amount of neutral silica sol. After stirring for 10 to 20 minutes, add the formula amount of triethanolamine and calcium sulfate. After stirring evenly, add the high-molecular polymer of formula quantity. Add the remaining amount of pure water and stir for 20 to 30 minutes to obtain a formaldehyde scavenger....

Embodiment 1

[0044] Preparation of High Molecular Polymers

[0045] (1) Add 60 parts by weight of water to 6 parts by weight of sodium p-styrene sulfonate and 1 part by weight of polyvinylpyrrolidone, stir evenly, add 2 parts by weight of acrylic acid, fully mix and let stand for 20 minutes, and fill it with nitrogen for 2 ~3 minutes. The reaction system was placed in a reaction box and heated for 15-20 minutes, and magnetic stirring was carried out while heating. After the temperature reached 40°C, the heating was stopped and the stirring was continued to obtain a mixed solution.

[0046] (2) Turn on the ultraviolet lamp to irradiate the above mixed solution, and the irradiation intensity is 5mW / cm 2. Glucose solution (obtained by dissolving 2 parts by weight of anhydrous glucose in 3.2 parts by weight of purified water) was added during the irradiation process to make the mixed solution undergo polymerization reaction. The reaction time is 10-13 hours.

[0047] (3) When the mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com