Application of hydroxyl compound in high-voltage lithium ion battery and high-voltage lithium ion battery

A lithium-ion battery, high-voltage technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of reduced structural stability of positive electrode materials, irreversible attenuation of capacity, and structural collapse of positive electrode materials. To achieve the effect of improving cycle stability, not easy to oxidize and decompose, and avoiding reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] Exemplarily, the preparation method of the high-voltage lithium-ion battery electrolyte includes the following steps: uniformly mixing the solvent after removing water and impurities with conductive lithium salt, and then uniformly mixing with the above-mentioned functional additives.

[0090] Preferably, the solvent uses one or more of activated carbon, 3A molecular sieve, 4A molecular sieve, calcium chloride, anhydrous calcium oxide, and calcium hydride to remove water and impurities. Preferably, the 3A molecular sieve or the 4A molecular sieve is activated and then used for water and impurity removal, which can be activated by means of heating, purging, ammonia flushing or adsorbent adsorption.

[0091] Preferably, the temperature when the solvent is mixed with the conductive lithium salt is 20-40°C.

[0092] Preferably, the mixing speed when the solvent is mixed with the conductive lithium salt is 200-1500 r / s.

[0093] Preferably, the mixing time of the solvent an...

Embodiment 1-9

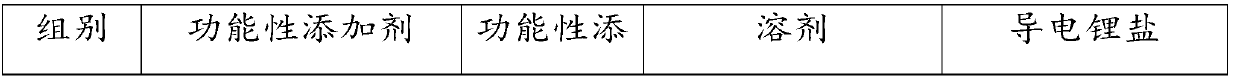

[0113] A high-voltage lithium-ion battery electrolyte, which includes a solvent, a conductive lithium salt, and functional additives, and the formulations of the electrolytes in each embodiment are listed in Table 1.

[0114] Table 1

[0115]

[0116]

[0117] The difference between embodiment 2 and embodiment 1 is that embodiment 2 adopts the preferred polyether polyol of the present invention as a functional additive;

[0118] The difference between embodiment 3 and embodiment 2 is that embodiment 3 has adopted the preferred polyoxypropylene diol of the present invention as functional additive;

[0119] The difference between embodiment 4 and embodiment 2 is that the addition amount of the functional additive in embodiment 4 is within the preferred range of the present invention;

[0120] The difference between Example 6 and Example 5 is that the concentration of the conductive lithium salt in Example 6 is within the preferred range of the present invention.

[0121]...

Embodiment 10-18

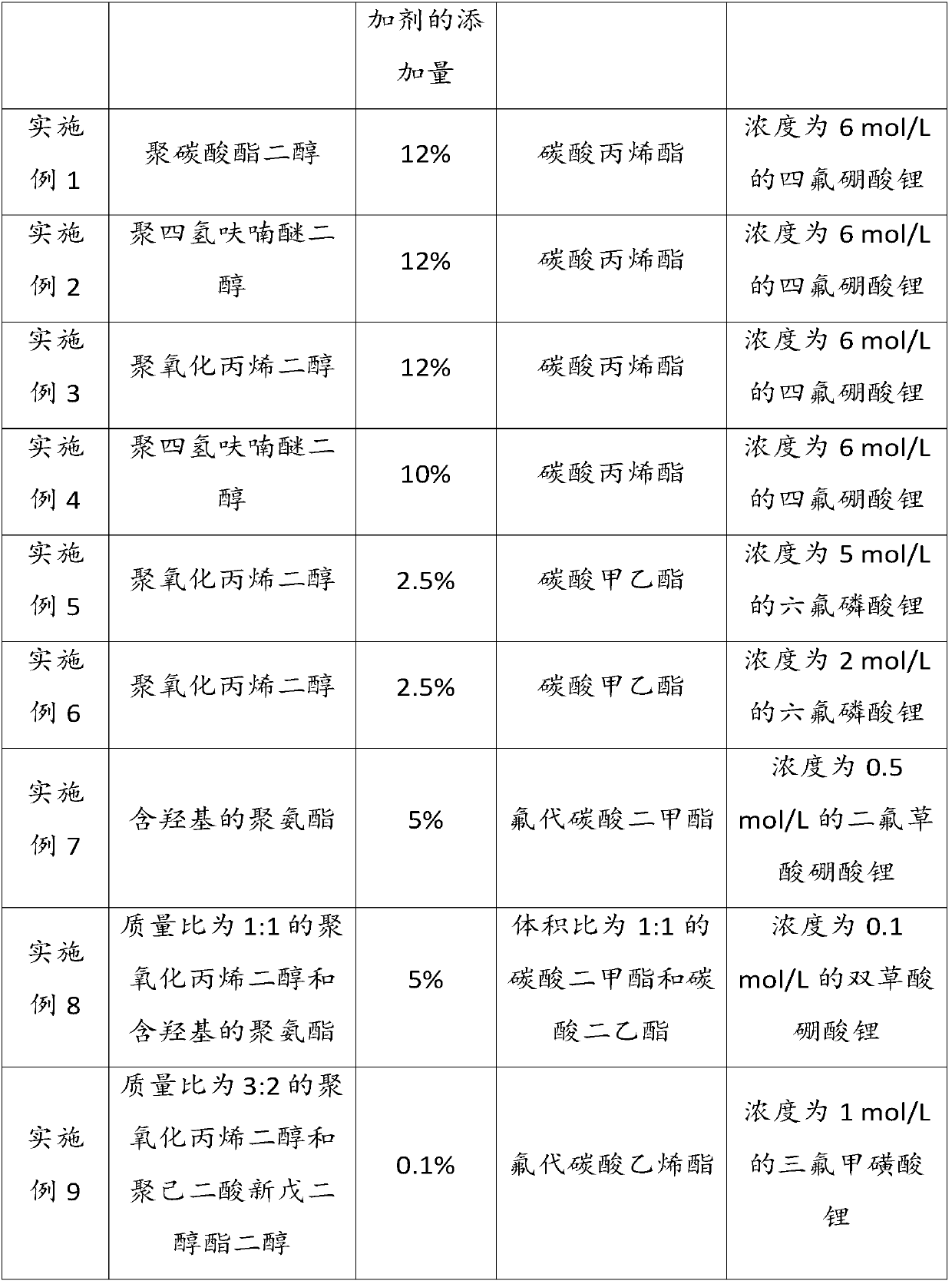

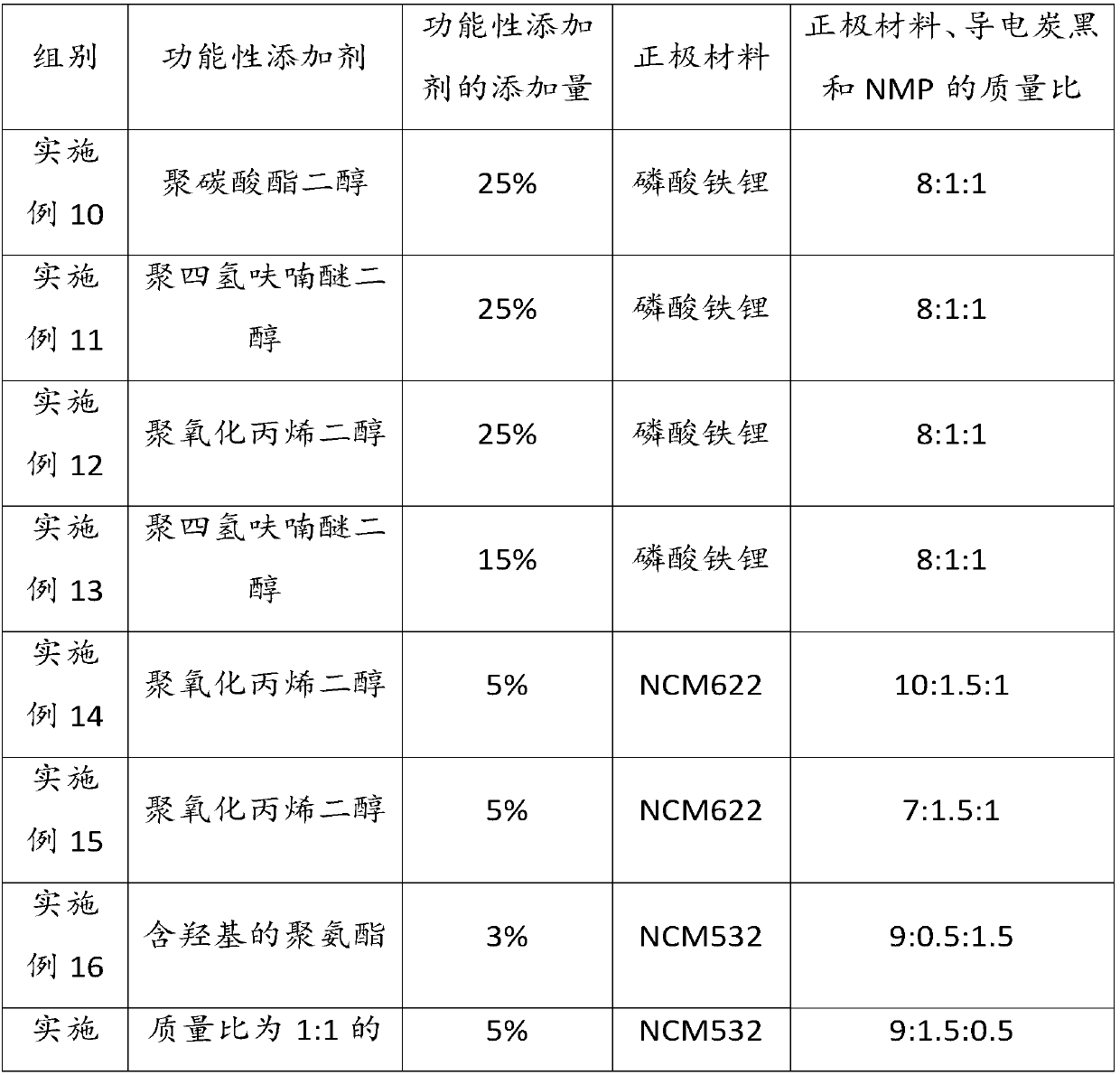

[0124] A positive electrode slurry for a high-voltage lithium ion battery, the positive electrode slurry includes positive electrode materials, conductive carbon black, NMP, and functional additives. The formulations of the positive electrode slurries in each embodiment are listed in Table 2.

[0125] Table 2

[0126]

[0127]

[0128] Note: NCM622 refers to LiNi 0.6 co 0.2 mn 0.2 o 2 , NCM532 means LiNi 0.5 co 0.3 mn 0.2 o 2 .

[0129] The difference between Example 11 and Example 10 is that Example 11 uses the preferred polyether polyol of the present invention as a functional additive;

[0130] The difference between embodiment 12 and embodiment 11 is that embodiment 12 adopts the preferred polyoxypropylene diol of the present invention as a functional additive;

[0131] The difference between Example 13 and Example 11 is that the amount of functional additive added in Example 13 is within the preferred range of the present invention;

[0132] The differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com