A thermal energy reuse device for a combined power generation device

A technology of combined power generation and thermal energy, applied in the direction of fuel cell heat exchange, circuit, fuel cell, etc., to achieve the effect of improving energy utilization, simplifying the system, and saving supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

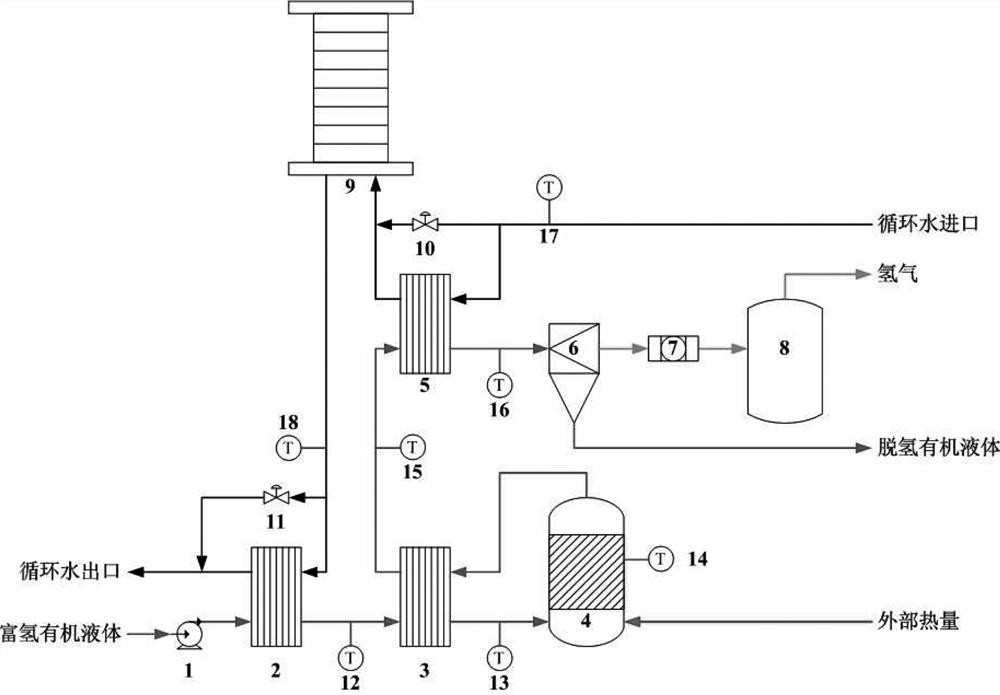

[0020] refer to figure 1 As shown, a combined power generation device thermal energy reuse device, based on a combined power generation device composed of a dehydrogenation reactor 4 and a proton exchange membrane fuel cell 9, includes a first-stage preheater connected to the outlet and the inlet of the proton exchange membrane fuel cell 9 respectively. 2 and cooler 5, connect the secondary preheater 3 of the outlet of the dehydrogenation reactor 4, and the steam-water separator 6 connected with the cooler 5, the steam-water separator 6 is connected to the hydrogen storage tank 8 through the filter 7, At the same time, the dehydrogenated organic liquid is output; the outlet of the proton exchange membrane fuel cell 9 is connected to the medium inlet of the primary preheater 2, the medium outlet of the primary preheater 2 is connected to the circulating water outlet, and the circulating water inlet is connected to the cooler 5 The medium inlet of the cooler 5 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com