Method for preparing titanium oxide coated sulfur-doped carbon nanotube lithium-sulfur battery cathode material

A technology of carbon nanotubes and titanium dioxide, which is applied in the field of preparation of titanium dioxide-coated sulfur-doped carbon nanotube lithium-sulfur battery cathode materials, can solve the problems of capacity fading, low conductivity of sulfur materials, poor battery cycle performance, etc., and achieve high Effects of initial charge-discharge capacity, low manufacturing cost, and high electron transport capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

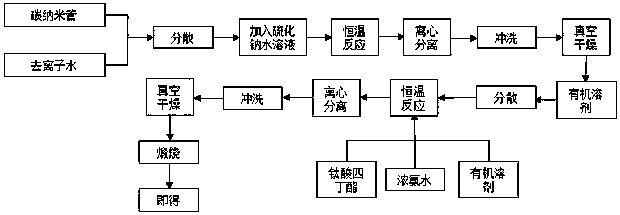

[0022] A method for preparing a titanium dioxide-coated sulfur-doped carbon nanotube lithium-sulfur battery positive electrode material, comprising the steps of:

[0023] S1. Preparation of sulfur-doped carbon nanotubes: adding carbon nanotubes to deionized water, ultrasonic dispersion treatment, adding sodium sulfide aqueous solution to the carbon nanotube dispersion, adding the mixed liquid into the reaction kettle, Constant temperature reaction, after the reaction is completed, it is centrifuged to obtain a solid, then washed with deionized water and ethanol, and vacuum-dried to prepare sulfur-doped carbon nanotubes.

[0024] S2. Preparation of titanium dioxide-coated sulfur-doped carbon nanotubes: Add concentrated ammonia water and tetraethyl titanate into the organic solvent, stir evenly, and record it as liquid A, add the sulfur-doped carbon nanotubes prepared in step S1 into an organic solvent, ultrasonic dispersion treatment, to obtain a sulfur-doped carbon nanotube di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com