Method for manufacturing longitudinal and radial water-blocking medium-voltage power cable and cable

A manufacturing method and power cable technology, applied in the direction of power cables, cable/conductor manufacturing, and power cables with shielding layers/conductive layers, etc., can solve the problems of corrosion of metal layers of steel strips and copper strips, explosion injuries, and reduction of cable electrical Performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

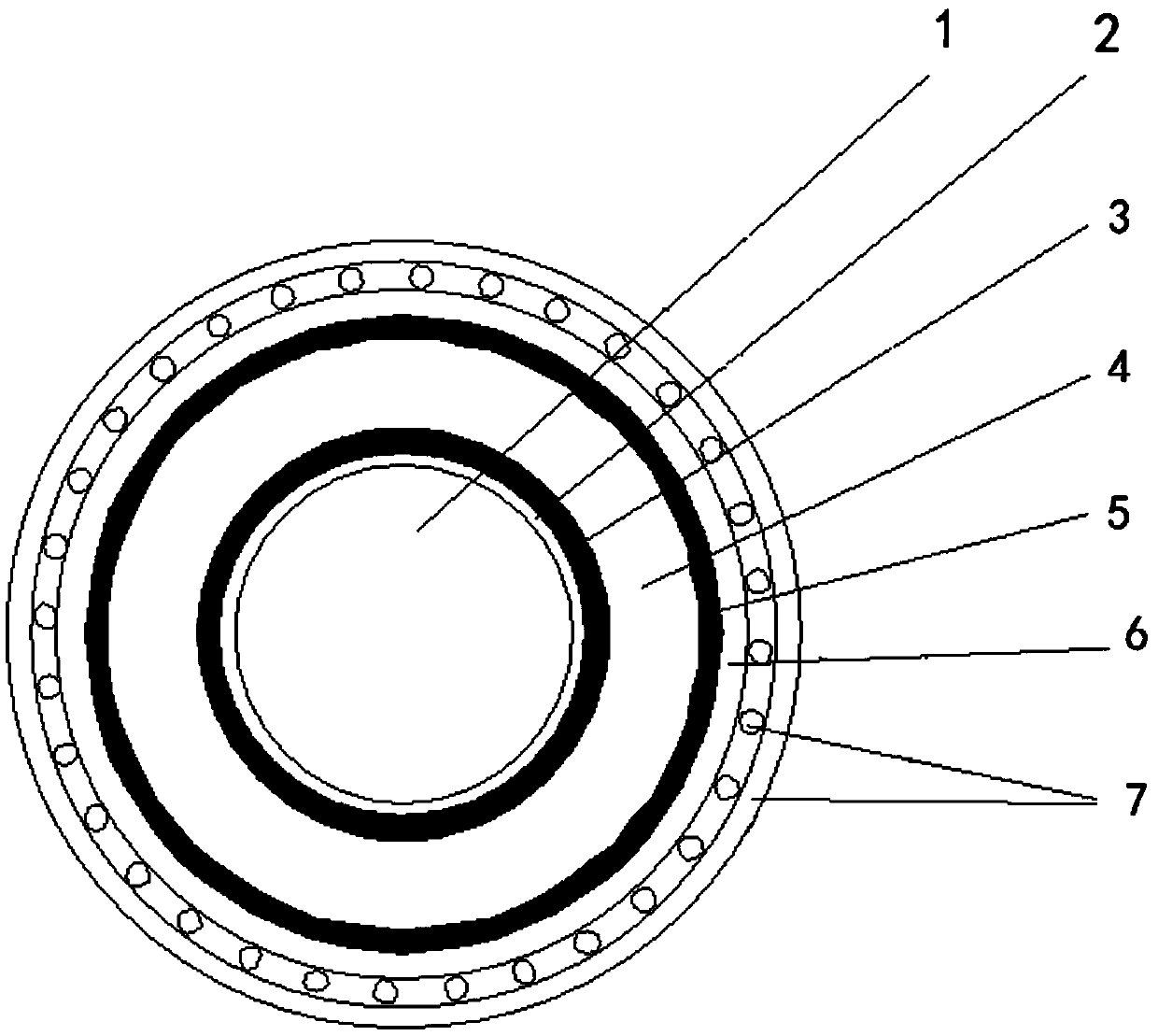

[0104] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

[0105] A method for manufacturing a longitudinal and radial water-blocking high-voltage power cable and the cable, specifically:

[0106] A longitudinal and radial water-blocking high-voltage power cable, the steps include: 1) manufacturing a wire core; 2) manufacturing a cable core; 3) manufacturing a protective layer, which is characterized in that

[0107] Described step 1) comprises:

[0108] 1.1) Prepare conductor;

[0109] 1.2) Wrap the first layer of water-resistant expansion tape, semi-conductive conductor shielding layer, water-tree-resistant cross-linked polyethylene insulating layer and semi-conductive insulating shielding layer in sequence outside the conductor;

[0110] Described step 2) comprises:

[0111] 2.1) Wrapping the second layer of water-blocking expansion tape and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com