Uniform light shooting device used for there-dimensional digital microscope

A technology of digital microscopes and shooting devices, which is applied in the field of testing and inspection, and can solve the problems that the details of bright spots and dark places cannot be displayed, and the over-exposed and under-exposed areas where the shape cannot be observed, so as to avoid specular reflection phenomenon, the effect of improving image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

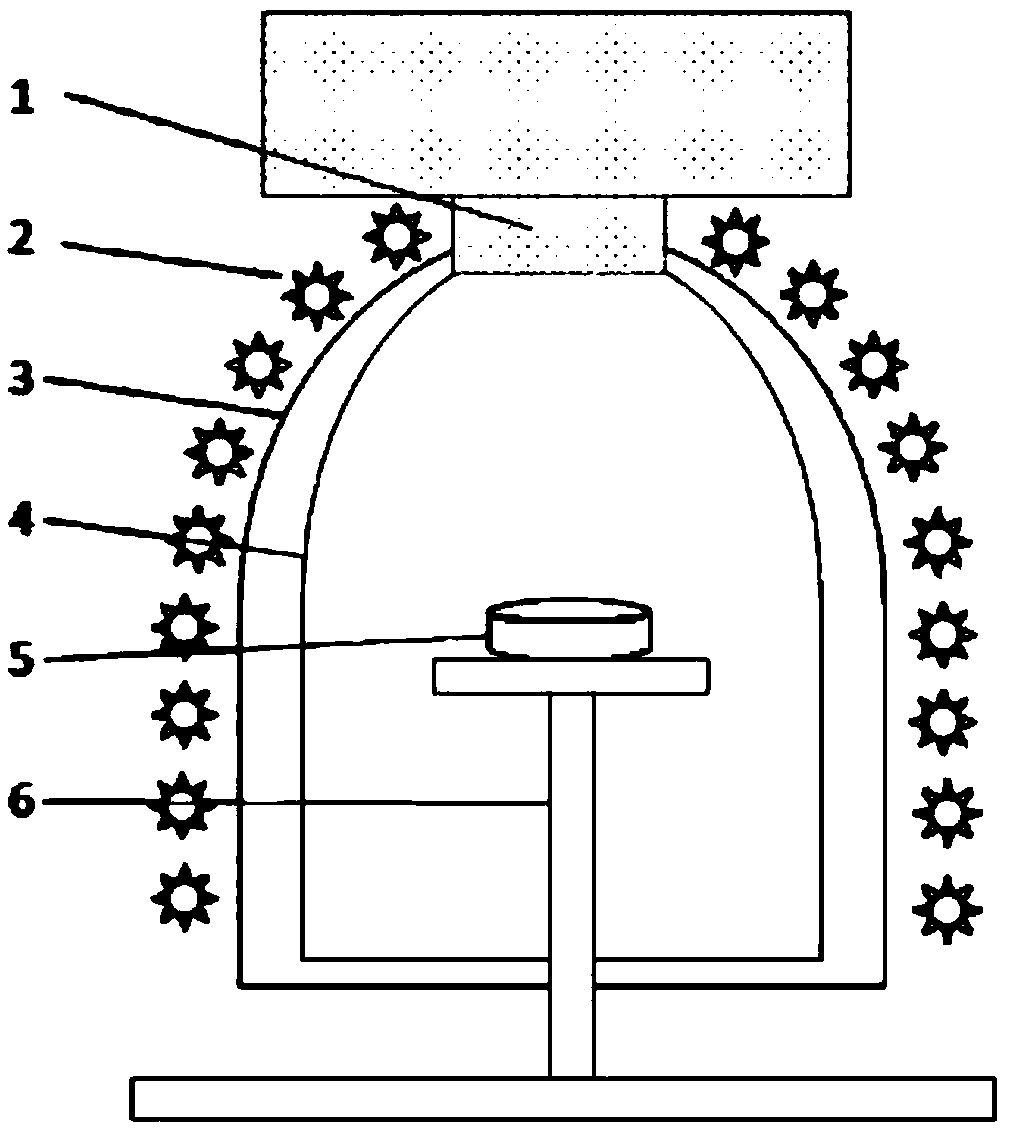

[0018] Such as figure 1 As shown, a uniform light shooting device for a three-dimensional digital microscope includes an LED light 2, an outer diffusion shed 3, an inner diffusion shed 4 and a stage 6, wherein the outer diffusion shed 3 and the inner diffusion shed 4 are both It has a bell-shaped structure and is made of semi-transparent materials; the inner diffusion shed 4 is installed inside the outer diffusion shed 3, and the tops of the outer diffusion shed 3 and the inner diffusion shed 4 are equipped with round holes, and the microscope lens 1 is embedded in the round holes There are multiple LED light lamps 2, which are arranged outside the outer diffusion shed 3; the stage 6 is placed in the inner diffusion shed 4, and when shooting, the object 5 to be photographed is placed on the stage for shooting.

[0019] Further, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com