Laser projection display screen with light absorption layer and preparing method and application thereof

A laser projection and display technology, applied in optics, instruments, projection devices, etc., can solve the problems of micro-display challenges, low yield, short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment provides a laser projection display screen containing a light absorbing layer and a preparation method thereof.

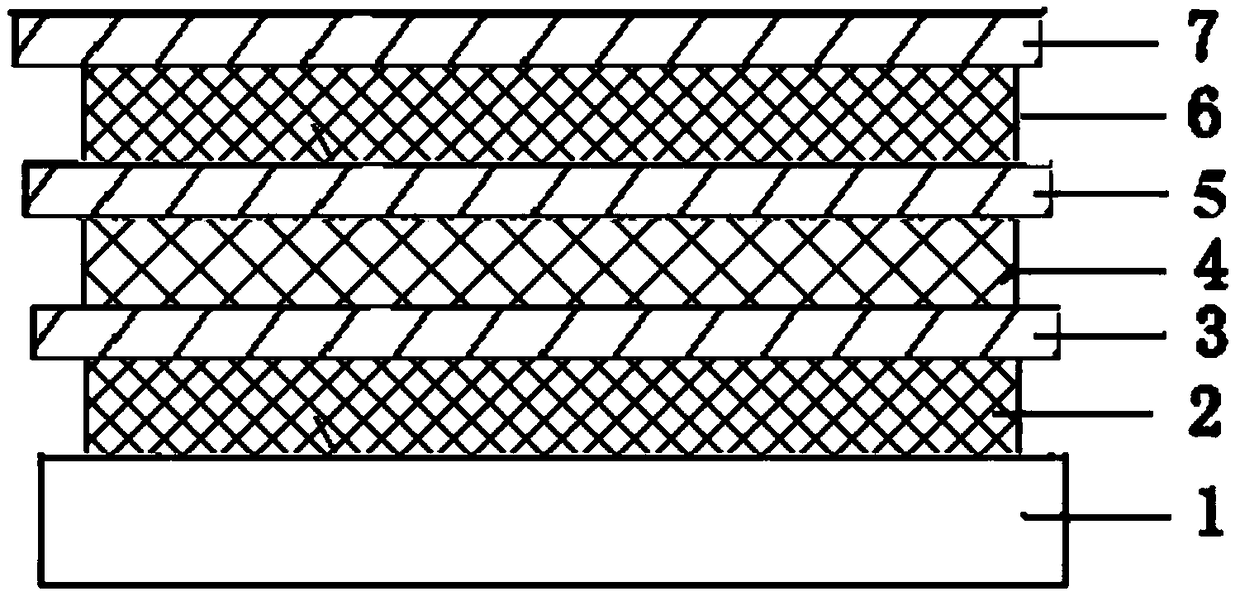

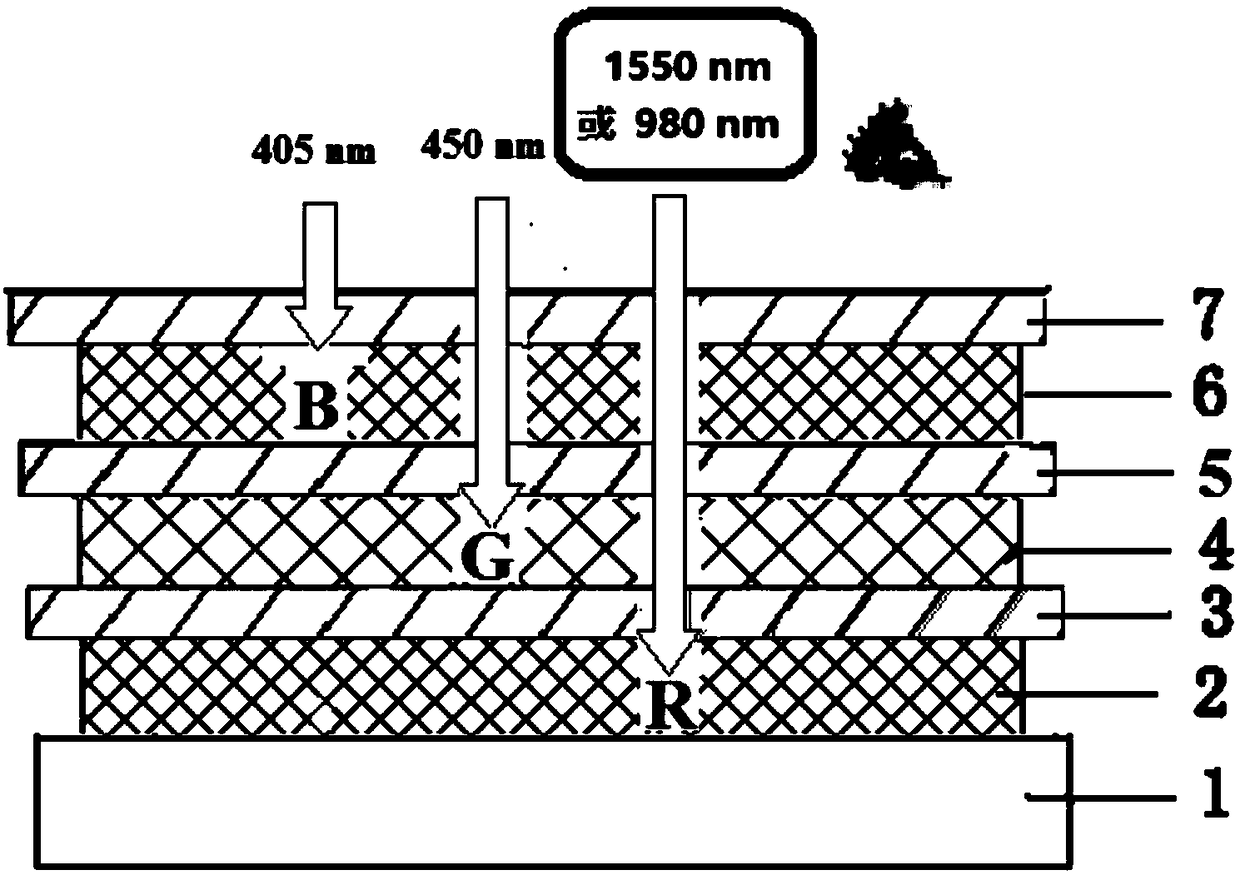

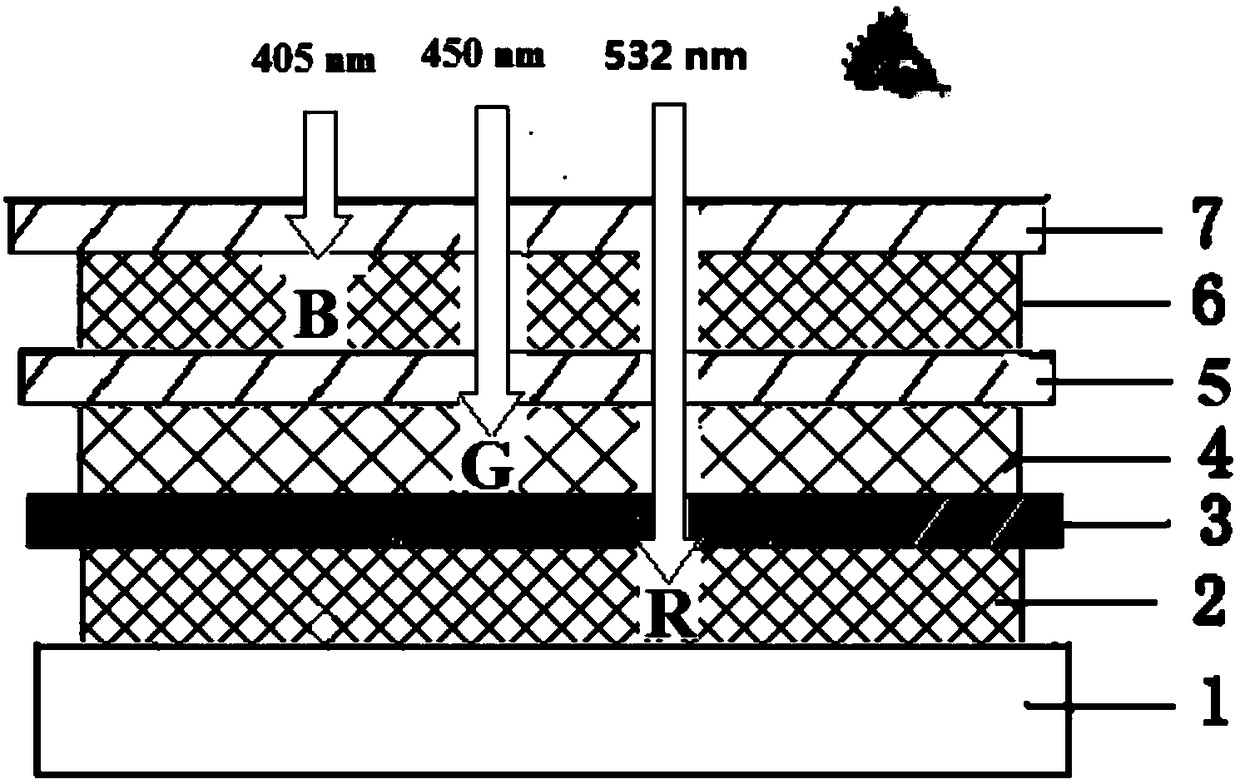

[0070] A laser projection display with a light-absorbing layer, such as figure 1 As shown, it consists of a substrate (1), an up-conversion luminescent material layer (2), an isolation layer (3), a green fluorescent material layer (4), a light-absorbing isolation layer I (5), a blue fluorescent material layer (6) and a protective Layers (7) are stacked successively.

[0071] The substrate 1 is made of glass.

[0072] The material of the up-conversion luminescent material layer is NaYF doped with ytterbium and erbium 4 ultrafine nanocrystals. Its preparation method is, Y 2 o 3 , Yb 2 o 3 and Er 2 o 3 According to the molar ratio m(Y 3+ ):m(Yb 3+ ):m(Er 3+ )=70:28:2 was dissolved in dilute hydrochloric acid to obtain a rare earth chloride precursor. Add 1 mmol of the above-mentioned rare earth chloride precursor dropwise into a mix...

Embodiment 2

[0094] This embodiment provides a laser projection display screen containing a light absorbing layer and a preparation method thereof.

[0095] The structure and preparation method of the display screen in this embodiment are the same as in Embodiment 1, the difference is that the material of the light-absorbing isolation layer I is polyimide containing light-absorbing groups, which has the following structural units:

[0096]

[0097] This structure can absorb light with a wavelength of less than 450nm, and the polyimide will not dissolve in toluene.

Embodiment 3

[0099] This embodiment provides a laser projection display screen containing a light absorbing layer and a preparation method thereof.

[0100] The structure and preparation method of the display screen in this embodiment are the same as in Embodiment 1, the difference is that the material of the light-absorbing isolation layer I is polyimide containing light-absorbing groups, which has the following structural units:

[0101]

[0102] This structure can absorb light before 450nm, and polyimide will not dissolve in toluene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com