A prepyrolysis type civil heating furnace and heating method thereof

A heating furnace, pre-pyrolysis technology, applied in the direction of combustion methods, water heaters, fluid heaters, etc., can solve the problems of poor environmental performance, low coal combustion efficiency, incomplete coal combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

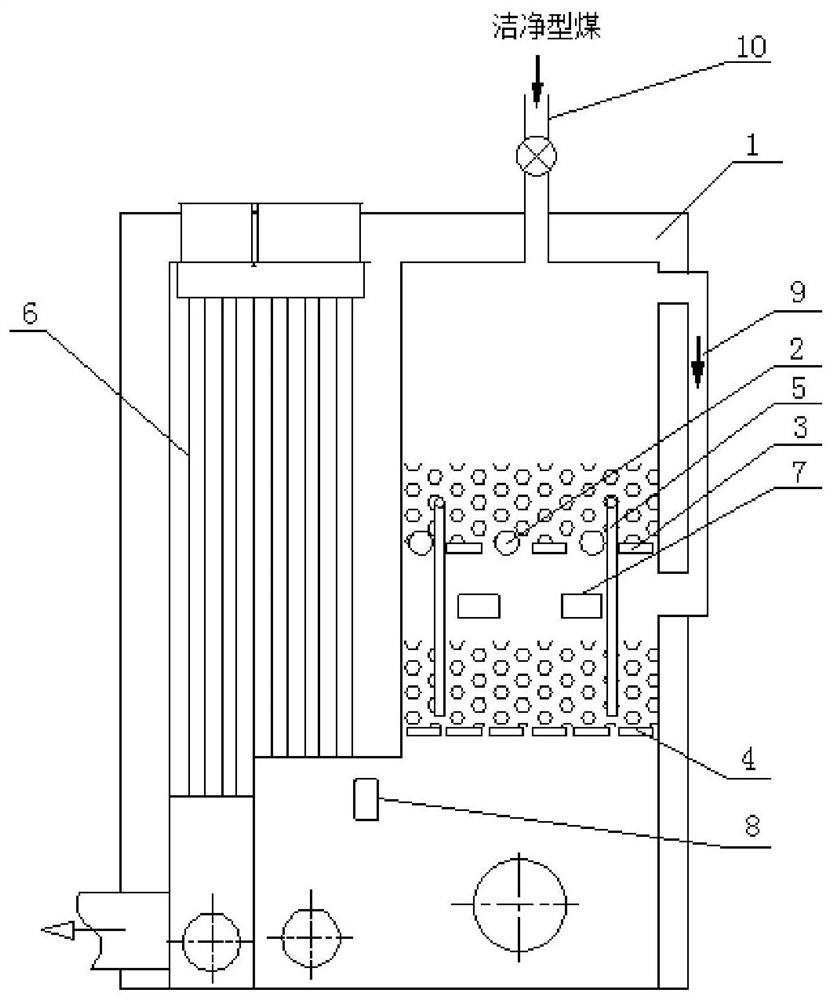

[0060] This embodiment provides a kind of pre-pyrolysis type civil heating stove and its treatment method, such as figure 1 As shown, the heating furnace includes a furnace body 1, and a longitudinal partition is arranged on the roof wall of the furnace body 1, which divides the interior of the furnace body 1 into a first chamber and a second chamber, and the first chamber and the second chamber The bottom of the chamber is connected, wherein the first chamber is a convection heat exchange zone 6, and the convection heat exchange zone 6 has built-in heat exchange tubes, and the middle part of the second chamber is equipped with a fire grate to divide the chamber into upper and lower regions. The top of the grate is an anaerobic pyrolysis zone, and the bottom of the grate is a semi-coke combustion zone. A charging port 10 is provided on the furnace wall exiting the anaerobic pyrolysis zone. The primary tuyere 7 is set between them, and the heat pipe 5 connecting the anaerobic p...

Embodiment 2

[0068] This embodiment provides a kind of pre-pyrolysis type civil heating stove and its treatment method, such as figure 2 As shown, the structure of the heating furnace refers to the structure in Example 1, the difference is that a pyrolysis gas conduit 9 is provided on the inner wall of the second chamber, and the pyrolysis gas conduit 9 is retained from the semi-coke combustion zone. The space extends into the anaerobic pyrolysis zone.

[0069] The method of using the heating furnace for heating refers to the method in Example 1, the only difference is that the oxygen volume content in the anaerobic pyrolysis process in step (a) is less than 2.5%, and the pyrolysis temperature is about 530-580 ° C. (2) The combustion temperature is 900°C to 950°C.

[0070] The coal-fired efficiency of the heating furnace described in this embodiment is> 88%, and the NO in the flue gas after combustion in the burnout zone x Emission concentration is less than 170mg / nm 3 , CO emission co...

Embodiment 3

[0072] This embodiment provides a pre-pyrolysis type civil heating furnace and its treatment method. The structure of the heating furnace refers to the structure in Embodiment 2.

[0073]The method of using the heating furnace for heating refers to the method in Example 1, the only difference is that the combustion temperature in step (2) is 810°C-850°C. The coal-fired efficiency of the heating furnace described in this embodiment is> 87%, and the NO in the flue gas after combustion in the burnout zone x Emission concentration is less than 190mg / nm 3 , CO emission concentration is less than 480mg / nm 3 , SO 2 Emissions below 290mg / Nm 3 , does not produce black smoke.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com