A high-efficiency track structure for Panmei orbital robot

An orbital robot and orbital technology, applied in instruments, optical devices, measuring devices, etc., can solve the problems of low coal coiling efficiency, inability to flexibly change the orbital structure according to demand, increase travel time and scan useless power, etc., and reduce coal coiling. Time, flexible coal coiling, and the effect of improving coal coiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

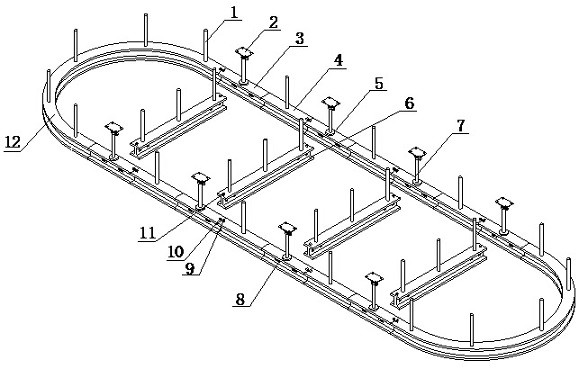

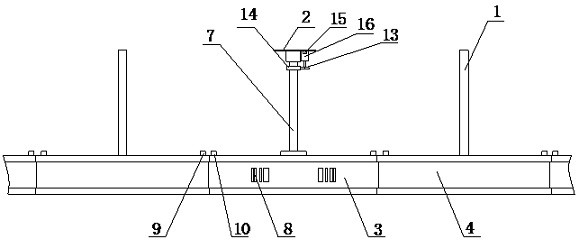

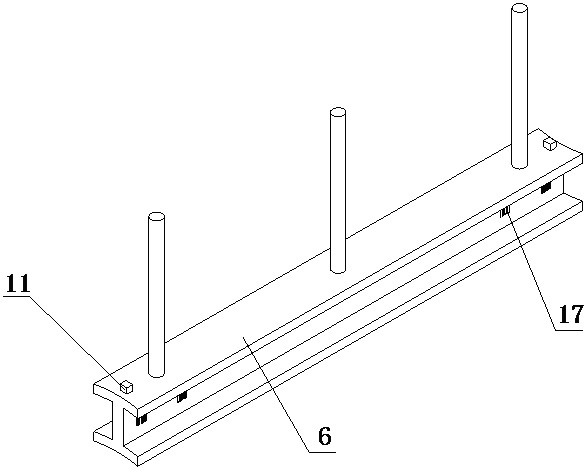

[0017] A high-efficiency track structure for a pan-coal track robot of the present invention is achieved in the following way: a high-efficiency track structure for a pan-coal track robot of the present invention is composed of a main device, a steering device and a transfer device, and the main device is composed of a suspension (1), fixed track (4), first infrared receiver (9) and U-shaped track (12), two fixed tracks (4) and two U-shaped tracks (12) are combined to form a straight circular track, The two U-shaped tracks (12) are respectively located at the two ends of the straight circular track, the two fixed tracks (4) are parallel, and the two ends of the U-shaped track (12) are respectively connected to the two fixed tracks (4) The corresponding ends of the fixed track (4) are disconnected to form multiple slots, the section of the slots is an arc surface, and there are multiple suspensions (1 ), the U-shaped track (12) is equipped with a plurality of suspensions (1), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com