Coking operation method for effectively improving production operation coefficient of coke oven

A technology of operation coefficient and operation method, which is applied in the field of coking, can solve the problems of inadequate equipment management and maintenance, unskilled workers, and low K3 coefficient, so as to improve the punctual rate of coal addition, reduce the number of times of coal discharge, and reduce the amount of residual coal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] (1) The specific method of operation of the coal loading car is as follows:

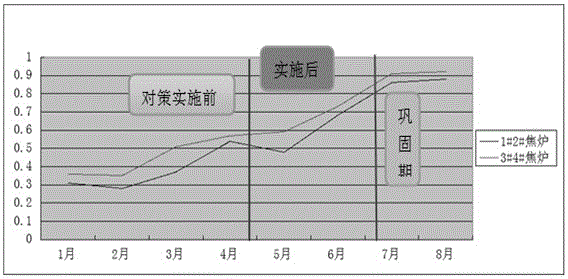

[0029] A. To optimize the coaling operation of the coaling vehicle, that is to adopt the new coaling method of "first 1# coke oven, 4# coke oven, then 2# coke oven, 3# coke oven". # coke oven, 4 # coke oven coal filling holes to add coal for 12 turns, then start to add 2 # coke ovens, 3 # coke ovens, and then add coal to the coal filling holes of 4 coke ovens at the same time; this operation method effectively improves Coal addition and reduced coal addition time; (The K3 coefficients of 1# coke oven, 4# coke oven, 2# coke oven and 3# coke oven are as follows figure 1 shown)

[0030] B. Stop the spiral when the coaling truck adds coal to 50 revolutions, and use low-speed coaling when the coal leveling starts; this operation method prevents smoke from the small furnace door and reduces the probability of coal extrusion;

[0031] C. Reset the running frequency conversion and spiral frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com