Method for treating tunnel collapse roof fall by using advanced small pipe pre-grouting technology

An advanced small conduit and pre-grouting technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as excessive gelation, delay the gelation time, compensate for the stability of surrounding rock, and improve strength and durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

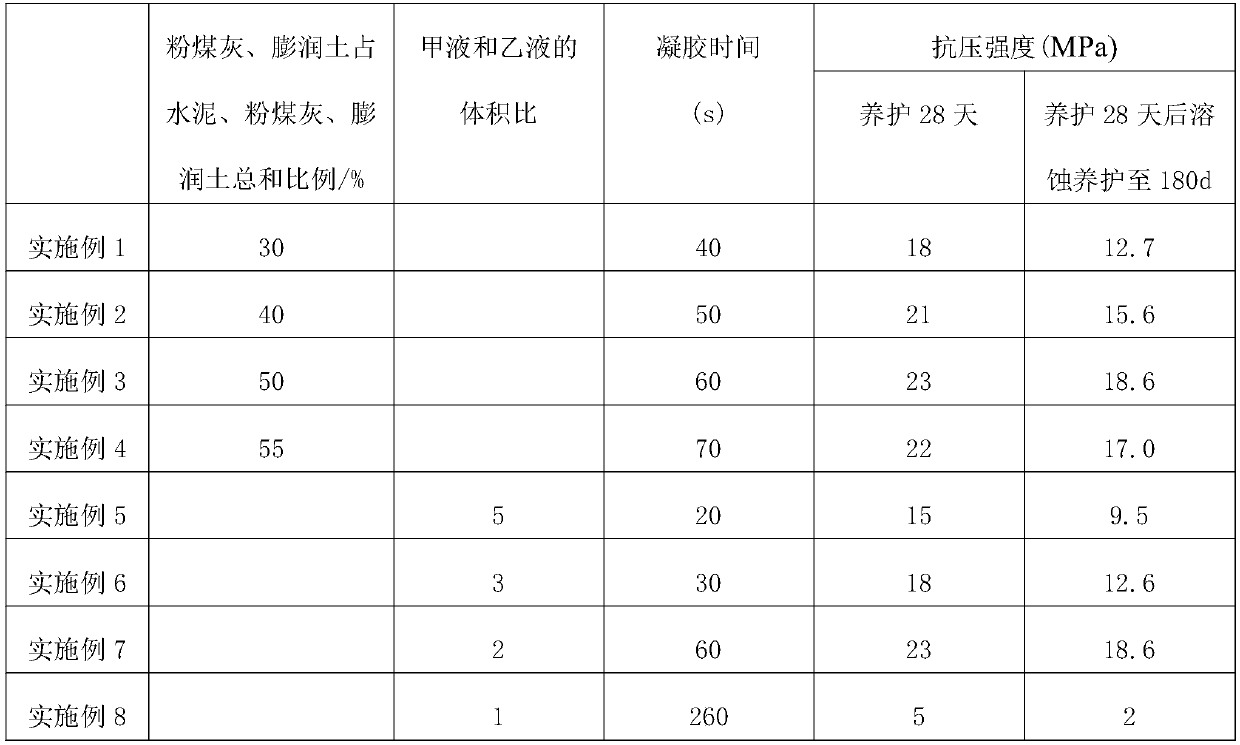

Examples

Embodiment 1

[0036] A method for treating tunnel collapse and roof fall by adopting an advanced small conduit pre-grouting process, comprising the following steps:

[0037] S1. Preliminary preparation: backfill the surface subsidence pit with grout, then complete the hardening and sealing treatment of the surface gullies, and do a good job of draining the gullies to ensure that the water in the gullies does not directly infiltrate.

[0038] S2. Advance small conduit pre-grouting: use the advanced small conduit pre-grouting process for construction.

[0039] The two-liquid grouting material includes liquid A and liquid B, and the liquid B is water glass; the liquid A includes the following components in parts by weight: 700 parts of cement, 200 parts of fly ash, 100 parts of bentonite, phosphoric acid 20 parts of disodium hydrogen, 10 parts of aluminum oxide, 10 parts of sodium hydroxide, and 1000 parts of water; uniformly mix liquid A and liquid B at a volume ratio of 1:0.5 to obtain the d...

Embodiment 2

[0046] A method for treating tunnel collapse and roof fall by using an advanced small conduit pre-grouting process. Compared with Example 1, the formula of the double-liquid grouting material in step S2 is different, and the other steps are the same.

[0047] The two-liquid grouting material includes liquid A and liquid B, and the liquid B is water glass; the liquid A includes the following components in parts by weight: 600 parts of cement, 300 parts of fly ash, 100 parts of bentonite, phosphoric acid 20 parts of disodium hydrogen, 10 parts of aluminum oxide, 10 parts of sodium hydroxide, and 1000 parts of water; uniformly mix liquid A and liquid B at a volume ratio of 1:0.5 to obtain the double-liquid grouting material.

[0048] Described water glass Baume degree is 35Be'. The cement is ordinary Portland cement with a strength of 42.5.

[0049] The moisture content of the fly ash is less than 0.2%, and the particle size is 15 μm.

Embodiment 3

[0051] A method for treating tunnel collapse and roof fall by using an advanced small conduit pre-grouting process. Compared with Example 1, the formula of the double-liquid grouting material in step S2 is different, and the other steps are the same.

[0052] The double-liquid grouting material includes liquid A and liquid B, and the liquid B is water glass; the liquid A includes the following components in parts by weight: 500 parts of cement, 300 parts of fly ash, 200 parts of bentonite, dihydrogen phosphate 20 parts of sodium, 10 parts of alumina, 10 parts of sodium hydroxide, and 1000 parts of water; uniformly mix liquid A and liquid B at a volume ratio of 1:0.5 to obtain the double-liquid grouting material.

[0053] Described water glass Baume degree is 35Be'. The cement is ordinary Portland cement with a strength of 42.5.

[0054] The moisture content of the fly ash is less than 0.2%, and the particle size is 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com