Titanium alloy surface adhesion promoter and preparation method thereof

An adhesion promoter, titanium alloy technology, used in coatings, epoxy resin coatings, etc., can solve the problem of low surface energy of titanium alloys, and achieve the effect of improving surface energy, improving adhesion, and promoting improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 4.3kg of epoxy resin E-44 and 17.7kg of mixed solvent (xylene: absolute ethanol = 1:1) into the reaction kettle, stir evenly, then heat up to 55°C ± 5°C, under stirring, 7.5kg The silane coupling agent KH-550 is added dropwise to the reaction kettle in 40 minutes. After the dropwise addition, the reaction temperature is controlled at 70-80° C., and the reaction is kept for 4 hours to obtain the adhesion promoter for the titanium alloy surface.

Embodiment 2

[0027] Add 4.3kg of epoxy resin E-44 and 20kg of mixed solvent (xylene: absolute ethanol = 1:1) into the reaction kettle, stir evenly, then heat up to 55°C±5°C, under stirring, 10kg of silane The joint agent KH-270 is added dropwise to the reaction kettle in 60 minutes. After the dropwise addition, the reaction temperature is controlled at 70-80°C, and the reaction is kept for 5 hours to obtain the adhesion promoter product for titanium alloy surface.

Embodiment 3

[0029] Add 4.3kg epoxy resin E-44 and 18.85kg mixed solvent (xylene: absolute ethanol = 1:1) into the reaction kettle, stir evenly, then heat up to 55°C±5°C, under stirring, 3.75kg Silane coupling agent KH-550 and 5kg of silane coupling agent KH-270 are added dropwise to the reaction kettle in 50 minutes. After the dropwise addition, the reaction temperature is controlled at 70-80°C, and the titanium alloy is obtained at 70-80°C for 4.5 hours. Adhesion promoter products for surfaces.

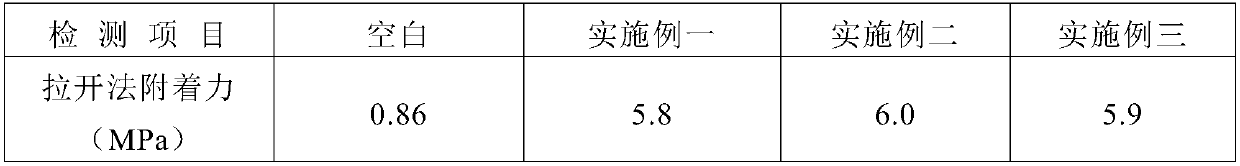

[0030] Implementation Effect

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com