Gas chromatography detection method for trace N,N-dimethyl formamide in synthesized leather

A technology of dimethylformamide and gas chromatography is applied in the field of detection of trace N,N-dimethylformamide in wet-process synthetic leather products, which can solve the problems of complicated operation, long time consumption and the like, and achieves good separation effect, Simple operation and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

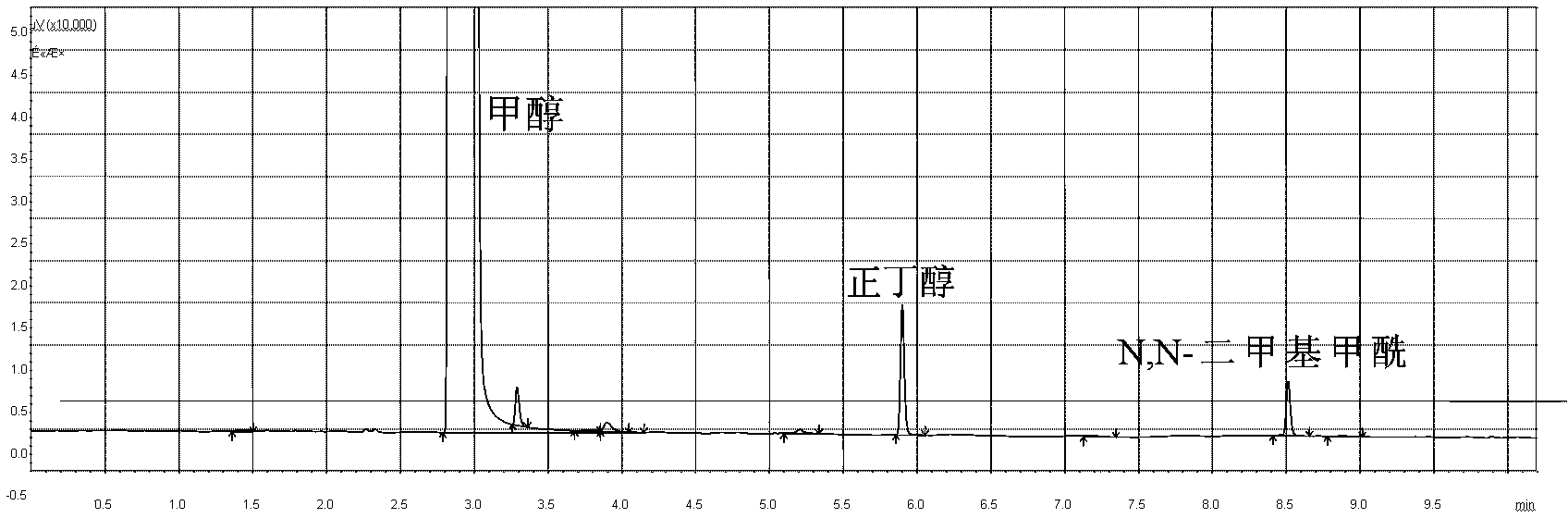

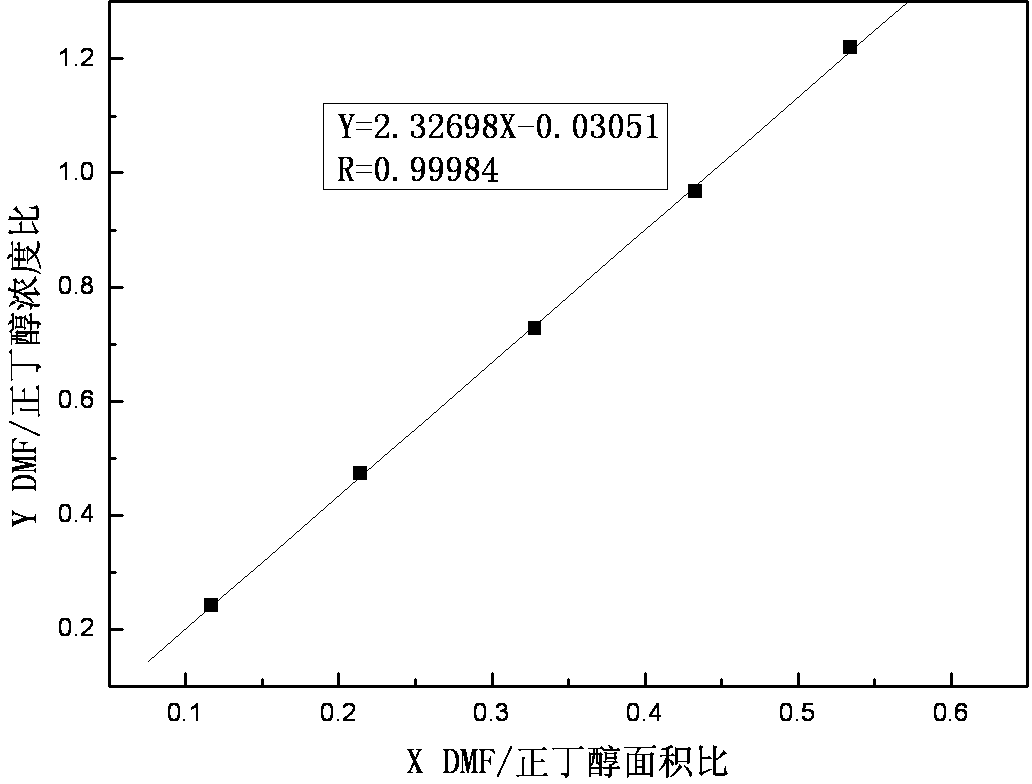

[0029] The specific operation steps of gas chromatographic detection of trace amounts of N,N-dimethylformamide in polyurethane synthetic leather are as follows:

[0030] (1) Preparation of N,N-dimethylformamide solution: add about 10mL of methanol in advance into a 25mL volumetric flask, then add 113.0mg of N,N-dimethylformamide, then add methanol to the scale line, and prepare a concentration of 4. 520mg / mL N,N-dimethylformamide solution;

[0031] (2) Prepare the internal standard solution: add about 10mL of methanol in advance into a 25mL volumetric flask, then add 1.000g of n-butanol, then add methanol to the mark, and prepare an internal standard solution of n-butanol with a concentration of 40mg / mL;

[0032] (3) Sample pretreatment: Weigh about 1g of the polyurethane synthetic leather to be tested (about 2mm×2mm) after being cut into pieces, add it to a 45mL screw cap sample bottle, and add 0.1mL of n-butanol internal standard solution with a concentration of 40mg / mL , a...

Embodiment 2

[0038] (1) Preparation of N,N-dimethylformamide solution: add about 10mL of methanol in advance into a 25mL volumetric flask, then add 362.0mg of N,N-dimethylformamide, then add methanol to the scale line, and prepare a concentration of 14.48mg / mL N,N-dimethylformamide solution;

[0039] (2) Prepare the internal standard solution: add about 10mL of methanol in advance into a 25mL volumetric flask, then add 1.000g of n-butanol, then add methanol to the mark, and prepare an internal standard solution of n-butanol with a concentration of 40mg / mL;

[0040] (3) Sample pretreatment: Weigh about 1g of the polyurethane synthetic leather to be tested (about 2mm×2mm) after being cut into pieces, add it to a 45mL screw cap sample bottle, and add 0.1mL of n-butanol internal standard solution with a concentration of 40mg / mL , accurately add 20mL of analytical pure methanol, and tighten the bottle cap to obtain the treatment A;

[0041] (4) Sample pretreatment for adding standard samples: ...

Embodiment 3

[0046] (1) Prepare N,N-dimethylformamide solution: add about 10mL of methanol in advance to a 25mL volumetric flask, then add 232.4mg of N,N-dimethylformamide, then add methanol to the scale line, and prepare a concentration of 9. 296mg / mL N,N-dimethylformamide solution;

[0047] (2) Prepare the internal standard solution: add about 10mL of methanol in advance into a 25mL volumetric flask, then add 1.000g of n-butanol, then add methanol to the mark, and prepare an internal standard solution of n-butanol with a concentration of 40mg / mL;

[0048] (3) Sample pretreatment: Weigh about 1g of the polyurethane synthetic leather to be tested (about 2mm×2mm) after being cut into pieces, add it to a 45mL screw cap sample bottle, and add 0.1mL of n-butanol internal standard solution with a concentration of 40mg / mL , accurately add 20mL of analytical pure methanol, and tighten the bottle cap to obtain the treatment A;

[0049] (4) Sample pretreatment for adding standard samples: Weigh ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com