Nano magnetic ink and preparation method and application thereof

A magnetic ink and nano-magnetic technology, applied in ink, applications, household appliances, etc., can solve the problems of environmental protection and magnetic instability of magnetic ink, and achieve the effect of enhancing dispersion stability, increasing specific surface area, and expanding performance advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

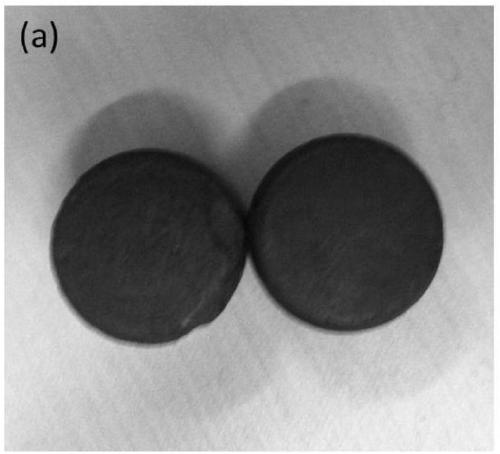

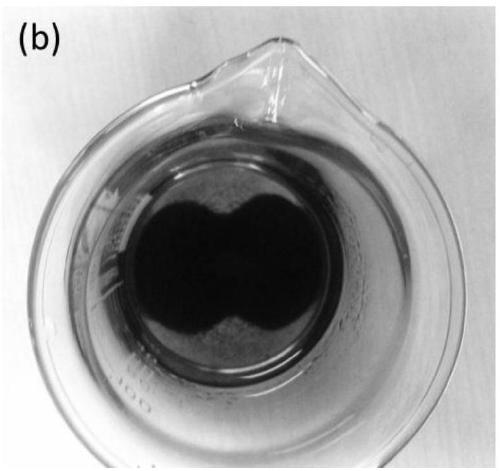

Image

Examples

preparation example Construction

[0052] In order to solve the problem of magnetic instability and easy precipitation of traditional ink, the invention provides a superparamagnetic ink and its preparation method and application.

[0053] In a preferred embodiment, the ink is prepared from the following raw materials and proportions (in parts by weight): 0.5-5 parts of modified (purified) carbon nanotubes, 18-35 parts of ethylene glycol, Ferric chloride hexahydrate (FeCl 3 ·6H 2 O) 5-20 parts, ethylenediamine 4-20 parts, sodium acetate 3-15 parts, ethanol 30-100 parts, deionized water 40-120 parts, water-based polyurethane 10-35 parts, methyl methacrylate 5- 20 parts, 3-13 parts of methyl acrylate, 2-12 parts of butyl acrylate, 1-5 parts of azobisisobutyronitrile, 1-8 parts of polyoxyethylene octylphenol ether-10 (OP-10), liquid 1-8 parts of paraffin, 1-8 parts of polysiloxane. Wherein, the modified (purified) carbon nanotubes are obtained by modifying the multi-walled carbon nanotubes in concentrated nitric...

Embodiment 1

[0069] In this embodiment, the raw materials in parts by weight in the following table are used to prepare magnetic ink.

[0070] Table 2 nanometer magnetic ink raw material ratio table (weight parts)

[0071]

[0072] (1) Weigh 3 parts of multi-walled carbon nanotubes (MWCNTs) into a 100mL beaker, add 10 parts of concentrated nitric acid solution, add 10 parts of deionized water to dilute, place in a 250W ultrasonic cleaner for 30 minutes, and disperse After uniformity, the MWCNTs were placed in a cooling reflux device and refluxed at 60°C for 12 hours to prepare purified MWCNTs; wherein, each part represented 1g;

[0073] (2) Weigh 1 part of purified MWCNTs into a beaker, add 25 parts of ethylene glycol as a dispersant, then seal the mouth of the beaker with a plastic film, place it in an ultrasonic cleaner, and ultrasonicate for 30 minutes in an ice bath environment ;

[0074] (3) 10 parts of FeCl 3 ·6H 2 O was ground into a powder in an agate mortar, and 5 parts of ...

Embodiment 2

[0085] In this embodiment, the raw materials in parts by weight in the following table are used to prepare magnetic ink

[0086] Table 3 nano magnetic ink raw material ratio table (weight parts)

[0087]

[0088] (1) Weigh 1 part of multi-walled carbon nanotubes (MWCNTs) into a 100mL beaker, add 5 parts of concentrated nitric acid solution, add 5 parts of deionized water to dilute, place in a 250W ultrasonic cleaner for 30 minutes, and disperse After uniformity, the MWCNTs were placed in a cooling reflux device and refluxed at 60°C for 12 hours to prepare purified MWCNTs; wherein, each part represented 1g;

[0089] (2) Weigh 0.5 parts of purified MWCNTs into a beaker, add 18 parts of ethylene glycol as a dispersant, then seal the mouth of the beaker with a plastic film, place it in an ultrasonic cleaner, and ultrasonicate for 30 minutes in an ice bath environment ;

[0090] (3) 5 parts of FeCl 3 ·6H 2 O was ground into powder in an agate mortar, and 3 parts of NaAc powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com