Low-volatility modified polypropylene composite material, preparation method and application thereof

A composite material, low-volatility technology, applied in the field of polymer materials, can solve problems such as the inability to meet the requirements of environmental friendliness of automotive interior trim materials, the difficulty of solving the core layer matrix odor and VOC, and achieve excellent thermal oxygen resistance. Aging performance, mechanical properties do not decline, the effect of reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

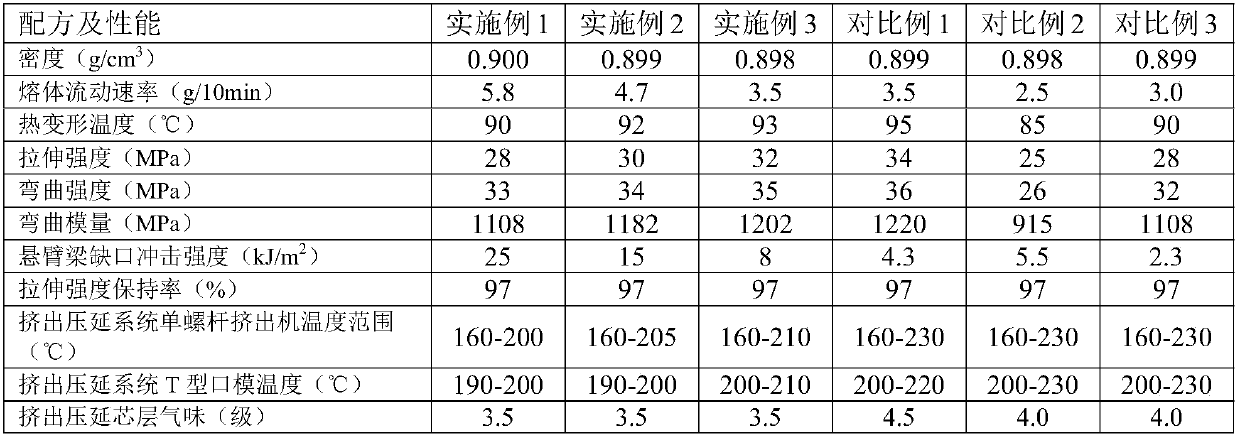

[0027] 60kg of low-flow homopolypropylene with a melt flow rate of 3.5g / 10min produced by Yanshan Petrochemical Company, 40kg of medium-flow high-impact polypropylene with a melt flow rate of 10.5g / 10min produced by Qilu Petrochemical Company, and 0.2kg Hindered phenolic antioxidant 1010, 0.3kg phosphite antioxidant 168, 0.3kg lubricant calcium stearate, 0.4kg furnace carbon black M717; add aspect ratio from the main feeding port of the screw extruder 40:1 co-rotating twin-screw extruder, melt blending; 160-200 ° C extrusion granulation, the test results and properties of the composite material obtained in Example 1 are shown in Table 1.

Embodiment 2

[0029] 50kg of low-fluidity polypropylene with a melt flow rate of 3.5g / 10min produced by Daqing Petrochemical Company, 50kg of medium-fluidity high-impact polypropylene with a melt flow rate of 12g / 10min produced by Lanzhou Petrochemical Company, and 1kg of hindered phenolic anti- Oxygen agent 1010, 0.5kg organic thiolipid antioxidant DSTP, 0.5kg lubricant EBS, 0.6kg thermal cracking carbon black N990; from the main feeding port at one end of the screw extruder, the length-to-diameter ratio is 36:1 In the co-rotating twin-screw extruder, carry out melt blending; After melt-blending in the co-rotating twin-screw extruder, 160-200 ℃ extrusion granulation, the test result performance of the composite material obtained in Example 2 is shown in the table 1.

Embodiment 3

[0031] 60kg of low fluidity polypropylene with a melt flow rate of 3.5g / 10min from Fushun Petrochemical, 40kg of medium fluid high impact polypropylene with a melt flow rate of 12g / 10min from Panjin Petrochemical, and 0.7kg of semi-hindered phenolic antioxidant 1790, 0.8kg phosphite antioxidant 168, 0.5kg lubricant monoglyceride stearate GMS, 0.5kg channel carbon black FW200; add the aspect ratio from the main feeding port at one end of the screw extruder Melt blending in a 40:1 co-rotating twin-screw extruder; melt-blending with other components in a co-rotating twin-screw extruder, extruding and granulating at 160-200°C, Example 3 The test results and properties of the obtained composite materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com