Polythiol composition for plastic optical lens

A technology of polymeric composition and polythiol, which is applied in optics, optical components, optical components, etc., can solve the problems of increased pulsation, rapid viscosity rise, etc., and achieve the effect of preventing pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

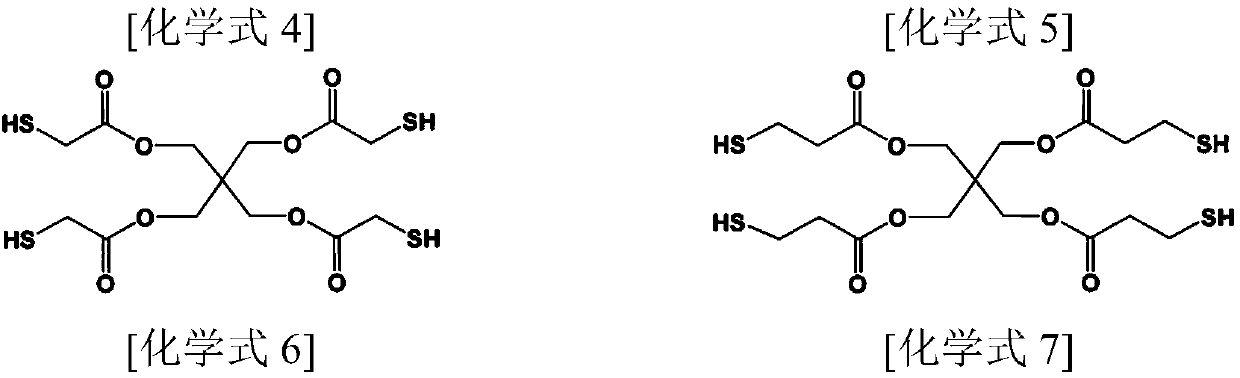

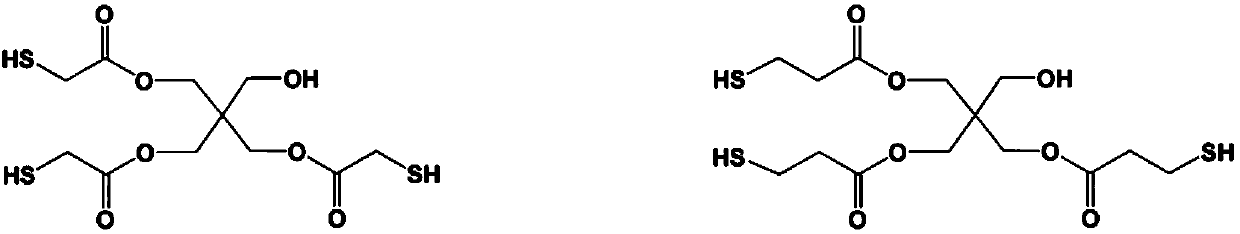

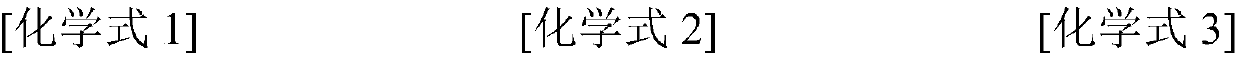

[0070] Synthesis example 1: Preparation of polythiol compound

[0071]

[0072] Put 187.5 grams (2.04 moles) of thioglycolic acid, 63.0 grams (0.46 moles) of pentaerythritol, 0.8 grams of p-toluenesulfonic acid, and 469.0 grams of toluene into a mechanical Stirrer, Dean-Stark containing a cooling tube, a thermometer connected to a temperature regulator, and a heater reactor, and stirred for 60 minutes, and then reacted at 130° C. for 8 hours. At this time, a nitrogen pipe was installed inside the reactor, and nitrogen gas was continuously injected to remove water generated during the reaction inside the reactor, thereby inducing the reaction to a positive reaction. At this time, the amount of water removed was 98.9% of the theoretical amount. Then, the temperature was lowered to room temperature, and alkali washing, acid washing, and water washing were sequentially performed to obtain an organic layer. The obtained organic layer was heated to remove the solvent under redu...

Synthetic example 2

[0074] Synthesis example 2: Preparation of polythiol compound

[0075]

[0076] Except having used 147.3 g (1.60 mol) of thioglycolic acid, 66.0 g (0.48 mol) of pentaerythritol, and 491.3 g of toluene, it carried out by the method similar to the said synthesis example 1. The amount of water removed during the above reaction was 98.5% of the theoretical amount.

[0077] As a result of the above reaction, 200.6 g of a polythiol composition having a main component of the polythiol compound represented by the above chemical formula 6 was obtained. As a result of analyzing the composition obtained above by the absolute calibration curve method, it contains 79% by weight of the polythiol compound represented by the above chemical formula 6, 20% by weight of the polythiol compound represented by the above chemical formula 4, except for the above chemical formula 4 and 1% by weight of other oligomer compounds other than 6.

Synthetic example 3

[0078] Synthesis Example 3: Preparation of polythiol compound

[0079]

[0080] In addition to 3-mercaptopropionic acid (3-mercaptopropionic acid) 193.5g (1.82mol), pentaerythritol 56.4g (0.41mol), p-toluenesulfonic acid (p-toluenesulfonic acid) 0.7g and toluene 420.0g into the reactor Otherwise, it was carried out in the same manner as in Synthesis Example 1 above. The amount of water removed during the above reaction was 99.0% of the theoretical amount.

[0081] As a result of the above reaction, 202.2 g of a polythiol composition having a main component of the polythiol compound represented by the above chemical formula 5 was obtained. As a result of analyzing the composition obtained above by the absolute calibration curve method, it contains 78% by weight of the polythiol compound represented by the above chemical formula 5, 2% by weight of the polythiol compound represented by the above chemical formula 7, except for the above chemical formula 5 and 20% by weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com