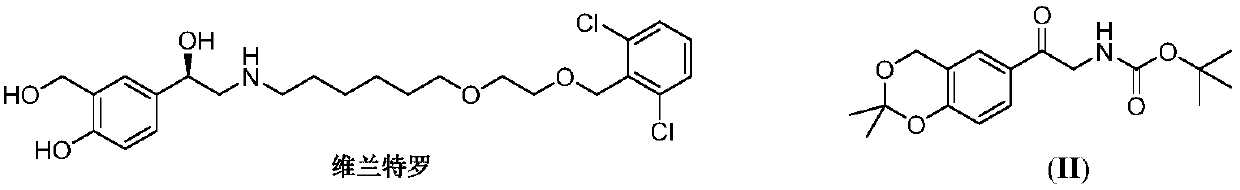

Method for synthesizing Vilanterol midbody by virtue of solid acid catalysis

A technology of solid acid catalysis and intermediates, applied in chemical recycling, organic chemistry, etc., can solve the problems of low yield, poor color, deep product color, etc., achieve simple post-processing, reduce environmental protection pressure, and increase productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

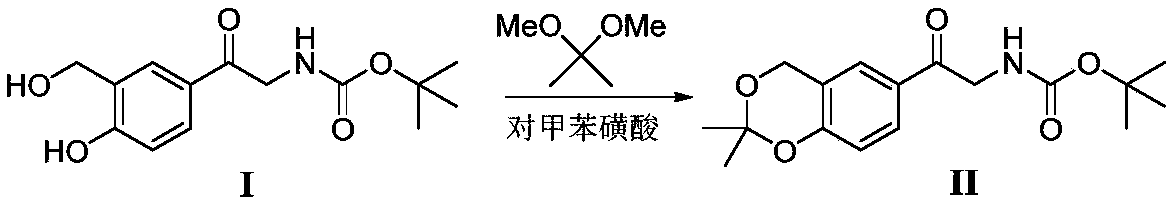

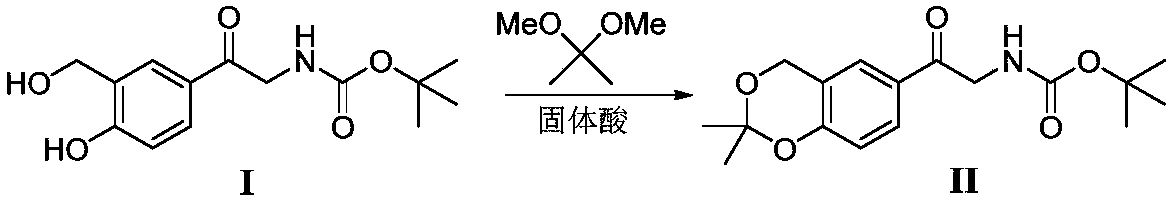

Method used

Image

Examples

Embodiment 1

[0020] Add 28.1g intermediate (I), 2,2-dimethoxypropane (20.8g), SO 4 2- / ZrO 2 (1.4g), add chloroform (140mL), heat up to 60°C, react for 2 hours, and the reaction is completed in TLC. Cool down to room temperature, filter, and concentrate the filtrate in vacuo to obtain a crude product, which is recrystallized from isopropyl ether to obtain 29.2 g of a white solid with a yield of 91% and a purity of 99%.

Embodiment 2

[0022] Add 28.1g intermediate (I), 2,2-dimethoxypropane (20.8g), SO 4 2- / TiO 2 (1.4g), add 1,2-dichloroethane (140mL), heat up to 55°C, react for 3 hours, and the reaction is completed in TLC. Cool down to room temperature, filter, and concentrate the filtrate in vacuo to obtain a crude product, which is recrystallized from isopropyl ether to obtain 29.5 g of a white solid with a yield of 92% and a purity of 99%.

Embodiment 3

[0024] Add 28.1g intermediate (I), 2,2-dimethoxypropane (20.8g), PO 4 3- / TiO 2 (1.4g), add acetone (140mL), heat up to 50°C, react for 3 hours, and the reaction is completed in TLC. Cool down to room temperature, filter, and concentrate the filtrate in vacuo to obtain a crude product, which is recrystallized from isopropyl ether to obtain 29.2 g of a white solid with a yield of 91% and a purity of 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com