Recovery method of trichloroethane in sucralose tail gas

A technology of trichloroethane and sucralose, which is applied in the disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., can solve the problems of difficult recovery and utilization of trichloroethane, and achieves simple methods, strong operational practicability, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

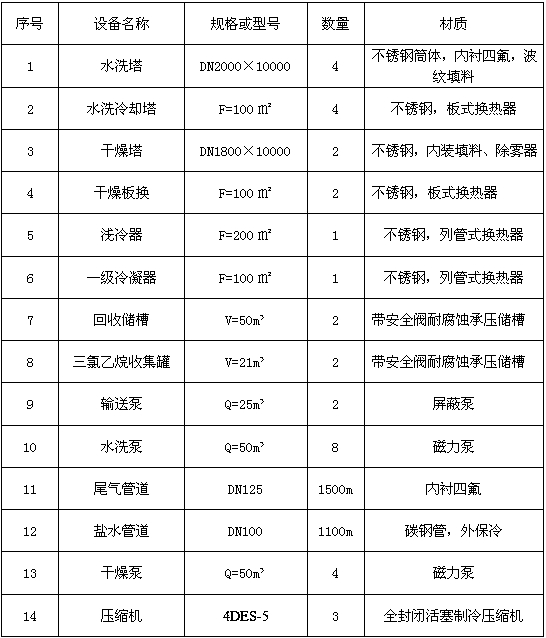

[0018] As shown in Table 1, the main equipment used in the present invention is shown in the following table.

[0019]

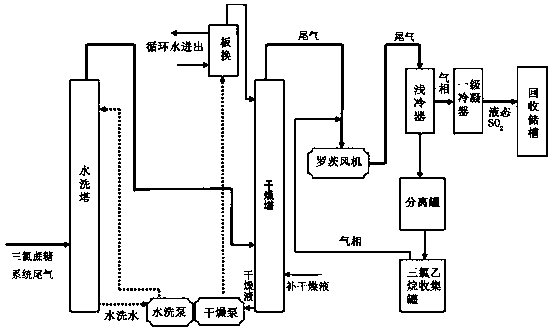

[0020] The sucralose tail gas first passes through the water washing tower to wash away the HCl contained in the tail gas. The water washing tower is equipped with a circulating water washing device and its connected water washing pump. When the Cl in the water washing tower - When ≥500ppm, concentrated water is extracted.

[0021] The tail gas treated by the washing tower passes through the drying tower to dry the remaining moisture in the tail gas. The drying tower is equipped with a circulating drying system and its connected drying pump. The purity of the concentrated sulfuric acid in the drying system is 92.5%~98%.

[0022] After drying, the exhaust gas enters the shallow cooler from the Roots blower. The inlet pressure of the Roots blower is set to -2KPa during normal operation. When the inlet pressure of the blower shows +1KPa, the Roots blower is started, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com