Spice wastewater treatment system

A wastewater treatment system and fragrance technology, applied in water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of difficulty in biochemical treatment, high operating costs, substandard effluent, etc. The effect of high waste treatment cost, saving operating cost and better effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

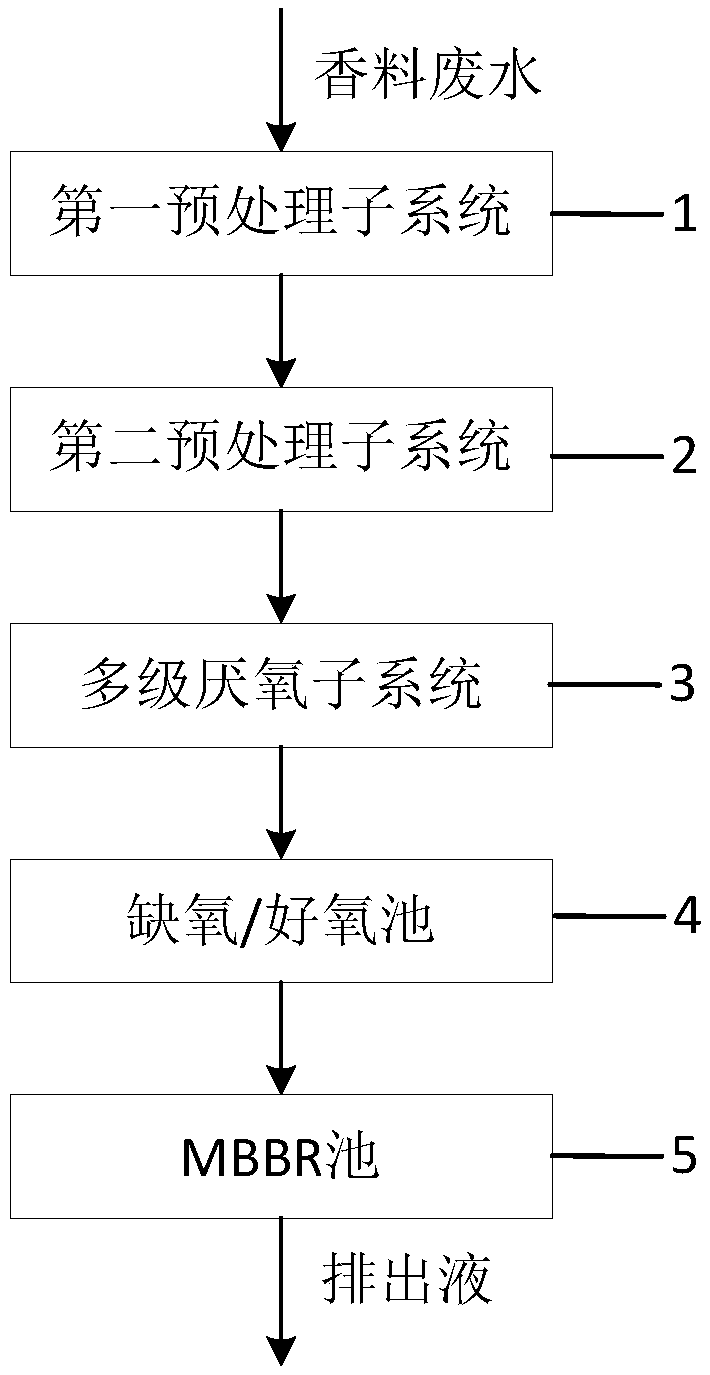

[0032] Such as figure 1 As shown, a spice wastewater treatment system includes a first pretreatment subsystem 1 for adjusting water quality and quantity and removing hardness in wastewater, and the spice wastewater treatment system also includes , removing salt, hydrolyzing insoluble organic matter into soluble organic matter, and converting difficult-to-biodegradable macromolecular substances into easily biodegradable small-molecular substances. Chemical oxygen demand, multi-stage anaerobic subsystem 3 for reducing organic matter content, said spice wastewater treatment system also includes anoxic / aerobic pool 4 and MBBR pool 5, said first pretreatment subsystem 1 is provided with spices Wastewater inlet, the MBBR pool 5 is provided with a discharge port, the first pretreatment subsystem 1, the second pretreatment subsystem 2, the multi-stage anaerobic subsystem 3, the anoxic / aerobic pool 4 and the MBBR pool 5 are connected through pipelines in turn.

Embodiment 2

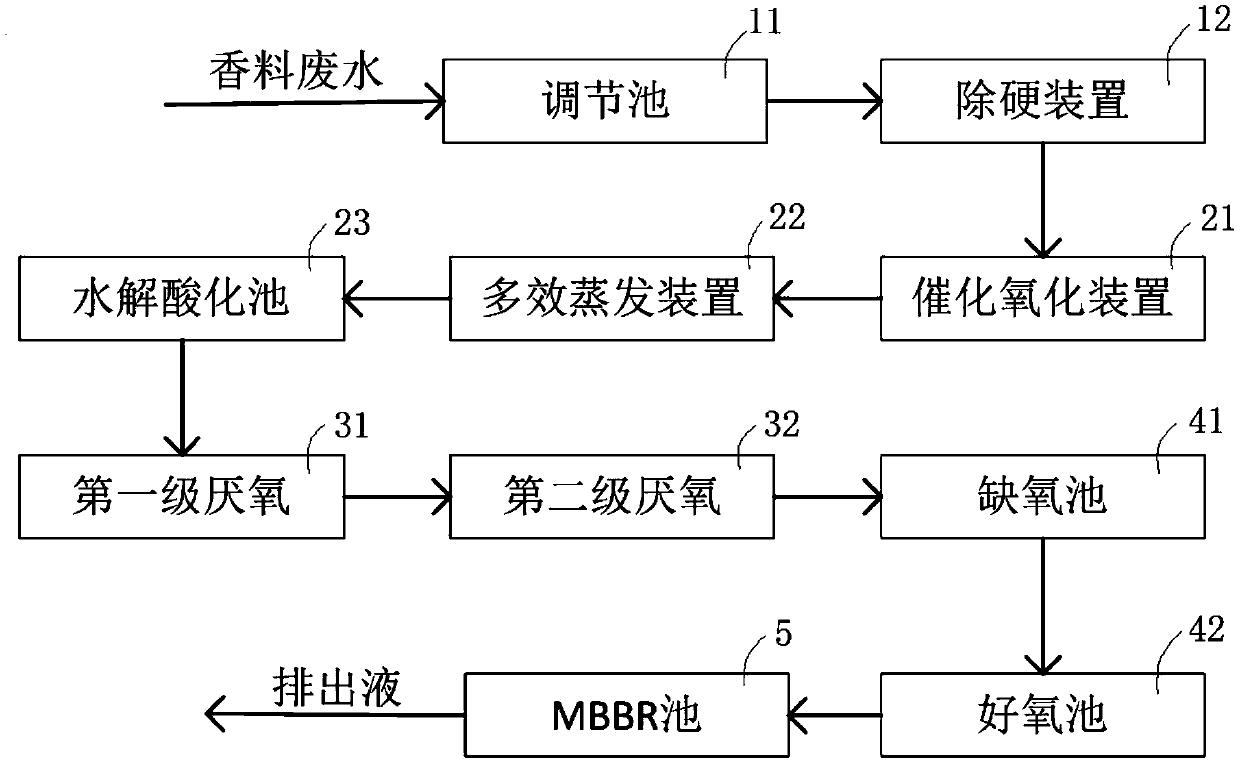

[0034] On the basis of Example 1, such as figure 1 , 2 As shown, the first pretreatment subsystem 1 includes a regulating tank 11 for adjusting water quality and quantity, and a hard removal device 12 connected with the regulating pond 11 for removing hardness in wastewater, and the regulating pond 11 is provided with spices Wastewater inlet, the hard removal device 12 is connected with the second pretreatment subsystem 2 through pipelines.

Embodiment 3

[0036] On the basis of embodiment 1 or 2, such as figure 1 , shown in 2, the second preprocessing subsystem 2 includes,

[0037] Catalytic oxidation device 21: used to reduce chemical oxygen demand and improve biodegradability;

[0038] Multi-effect evaporation device 22: used to remove salt;

[0039] Hydrolysis and acidification pool 23: used to hydrolyze insoluble organic matter into soluble organic matter, and convert difficult-to-biodegradable macromolecular substances into easily biodegradable small-molecular substances;

[0040] The catalytic oxidation device 21, the multi-effect evaporator 22 and the hydrolytic acidification tank 23 are sequentially connected through pipelines, and the catalytic oxidation device 21 is connected with the first pretreatment subsystem 1 or the hard removal device 12 through pipelines, so that The hydrolytic acidification tank 23 is connected with the multi-stage anaerobic subsystem 3 through pipelines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com