A method for degrading acephate in solution by electron beam irradiation

A technology of acephate and electron beam irradiation, applied in chemical instruments and methods, neutralized water/sewage treatment, light water/sewage treatment, etc., can solve the problems of high treatment cost, low degradation efficiency, and no , to achieve the effect of high technical application value, strong operational safety and good irradiation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

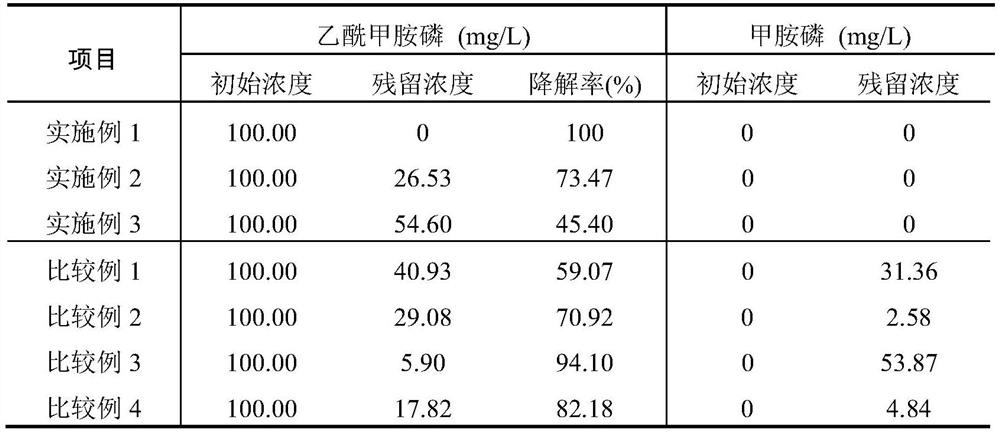

Examples

Embodiment 1

[0026] a) NaHCO 3 / H 2 CO 3 The buffer solution standard solution is added to the aqueous solution containing acephate, and the pH value of the solution is adjusted at 8;

[0027] b) the solution prepared in step a) is placed in a polyethylene composite packaging bag and filled with N 2 To the saturation state for packaging;

[0028] c) using an electron beam produced by an electron accelerator with an energy of 5-10 MeV, a beam current of 0.3-20 mA, and a beam power of 10-20 kW to irradiate the polyethylene composite packaging bag after step b) packaging, and control the temperature of the solution at 40 ℃, after irradiating a dose of 4.5kGy, open the package and fill it with O 2 , empty N 2 , making the solution O 2 Reach the saturated state, and then irradiate 4.5kGy at 30°C to make the total irradiation dose reach 9kGy;

[0029] d) During the operation of step c), the working temperature of the electron accelerator is set within the range of 5-35°C, the ambient humi...

Embodiment 2

[0031] a) K 2 HPO 4 / KH 2 PO 4 The pH buffer solution standard solution is added to the aqueous solution containing acephate, and the pH value of the solution is adjusted at 7;

[0032] b) the solution prepared in step a) is placed in a polyethylene composite packaging bag and filled with N 2 To the saturation state for packaging;

[0033] c) using energy of 5-10 MeV, beam current of 0.3-20mA, and beam power of 10-20kW electron beams produced by an electron accelerator to irradiate the polyethylene composite packaging bag after step b) packaging, and controlling the temperature of the solution at 50 ℃, after irradiating a dose of 2.5kGy, open the package and fill it with O 2 , empty N 2 , and then irradiate another 2.5kGy at 40°C to make the total irradiation dose reach 5kGy;

[0034] d) During the operation of step c), the working temperature of the electron accelerator is set within the range of 5-35°C, the ambient humidity is limited to no more than 60%, and the thic...

Embodiment 3

[0036] a) KHCO 3 / H 2 CO 3 The buffer solution standard solution is added to the aqueous solution containing acephate, and the pH value of the solution is adjusted at 7.5;

[0037] b) the solution prepared in step a) is placed in a polyethylene composite packaging bag and filled with N 2 To the saturation state for packaging;

[0038] c) using an electron beam produced by an electron accelerator with an energy of 5-10 MeV, a beam current of 0.3-20 mA, and a beam power of 10-20 kW to irradiate the polyethylene composite packaging bag after step b) packaging, and control the temperature of the solution at 30 ℃, after irradiating a dose of 1.5kGy, open the package and fill it with O 2 , empty N 2, and then irradiate another 1.5kGy at 20°C to make the total irradiation dose reach 3kGy;

[0039] d) During the operation of step c), the working temperature of the electron accelerator is set within the range of 5-35°C, the ambient humidity is limited to no more than 60%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com