Cathode vibration device for electrolytic machining

A vibrating device and cathode technology, which is used in machining electrodes, electric machining equipment, electrode manufacturing, etc., can solve problems such as stray corrosion, electrolytic machining cannot be carried out normally, and affecting machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

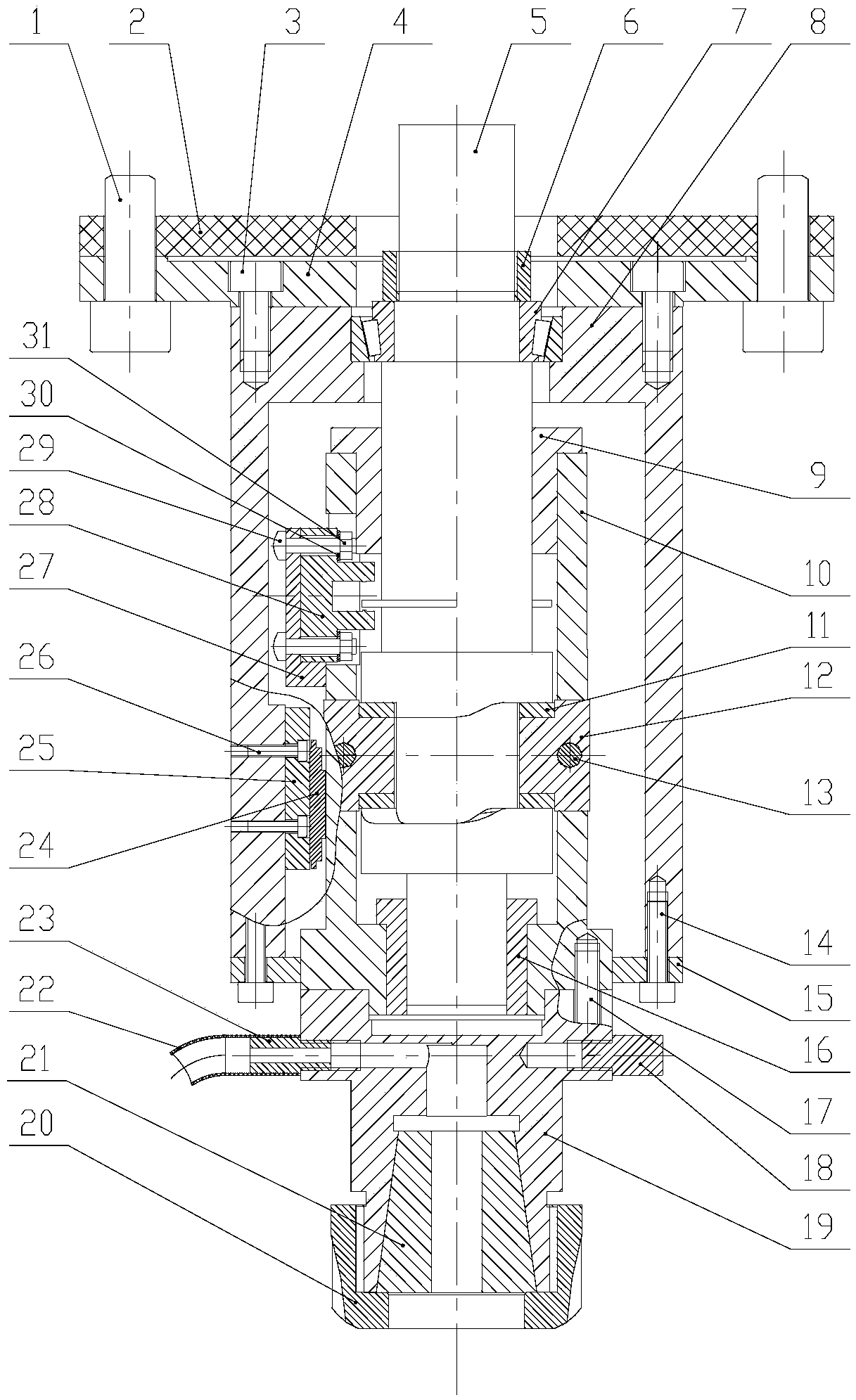

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

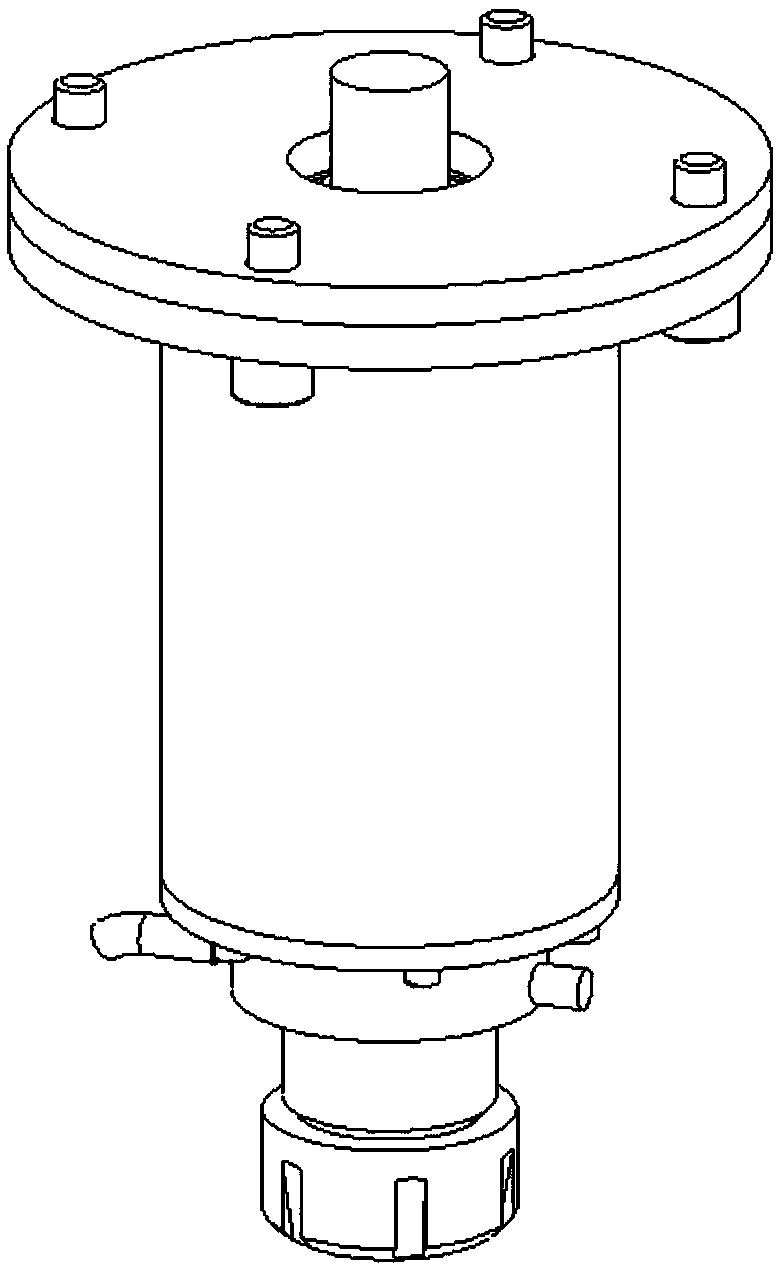

[0025] Such as figure 1 As shown, the electrolytic machining cathode vibration device of the present invention includes: damping screw 1, damping plate 2, first screw 3, connecting flange 4, camshaft 5, lock nut 6, tapered roller bearing 7, guide sleeve 8, Copper sleeve 9, vibration shaft 10, slider 11, slider shaft 12, cylindrical pin 13, second screw 14, guide sleeve cover 15, copper sleeve 16, third screw 17, cathode terminal 18, collet 19, clip Head lock nut 20, spring collet 21, conduit 22, breather pipe 23, MGN slider 24, MGN guide rail 25, fourth screw 26, bracket 27, photoelectric door 28, fifth screw 29, washer 30, nut 31.

[0026] The cathode vibrating device for electrolytic machining of the present invention is installed on the main shaft of the machine tool, wherein the camshaft 5 of the device rotates synchronously with the main shaft of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com