Automatic punching device for processing parts

A punching device and parts processing technology, which is applied in the field of parts processing, can solve the problems of punching position deviation and low degree of automation, and achieve the effect of high punching precision, high degree of automation, and good punching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

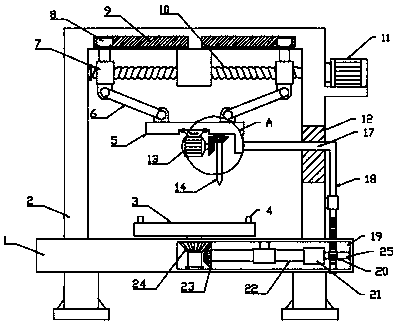

[0030] An automatic punching device for parts processing, comprising a bottom plate 1, a bracket 2, a placement table 3, a two-way threaded rod 10, and a transmission chamber 19; The gear D24 and the rotating shaft of the bevel gear D24 run through the transmission chamber 19 to the upper end of the workbench 1 and are fixedly connected to the lower end of the placement table 3. The upper end of the placement table 3 is provided with a fixing mechanism, which is set to fix the sheet to prevent the sheet from Movement occurs during punching.

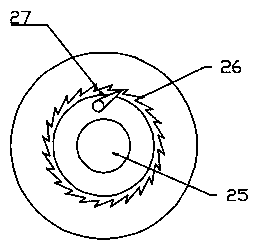

[0031] The right end of the bevel gear D24 is meshed with a bevel gear C23, and the bevel gear C23 is fixedly connected to the outside of the ratchet mechanism 21 through the second rotating rod 22. Preferably, the ratchet mechanism 21 includes a ratchet 26 and a pawl 27. The ratchet 26 is fixedly installed on the inner side of the ratchet mechanism 21, and the ratchet 27 is rotatably connected to the third rotating rod 25 through a torsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com