One-step preparation method of magnetic Cu(I) microspheric catalyst

A catalyst and microsphere technology, which is applied in the field of one-step preparation of magnetic Cu microsphere catalysts, can solve the problems of limited use efficiency and environmental factors of magnetic chitosan microspheres, and achieve the goals of improving catalyst separation performance, simple operation, and simplified preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

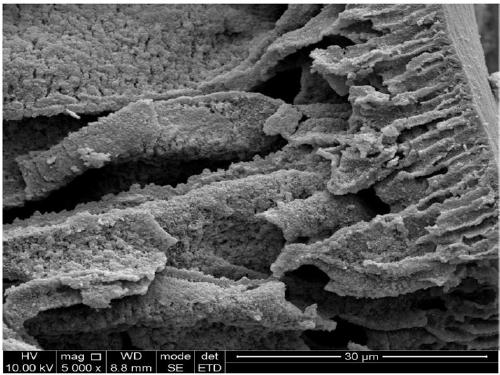

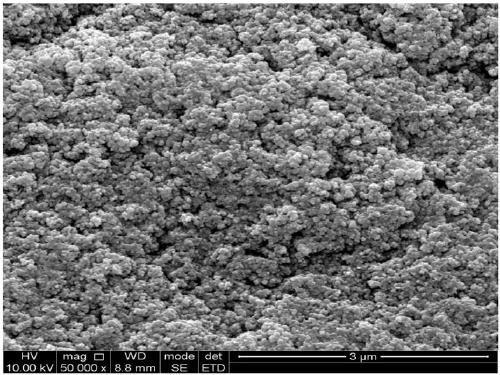

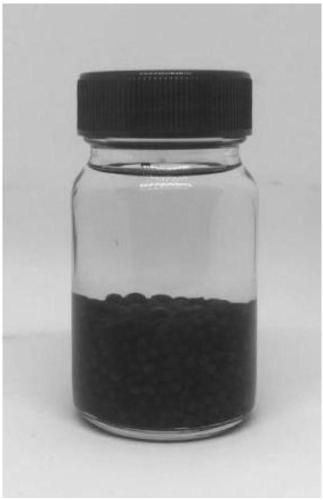

Embodiment 1

[0039]Weigh 2 g of α-chitosan powder, slowly add 100 mL of acetic acid (1% mass fraction) into a 250 mL beaker, stir at room temperature, and the chitosan is completely dissolved after about 2 hours. Due to the low solubility of copper acetate, 1.9963g of copper acetate monohydrate was added into a beaker of 50mL of acetic acid (1% by mass fraction), ultrasonically dissolved, and then slowly dropped into the chitosan solution after complete dissolution, and stirred at room temperature for 1h. 4.9703g ferrous chloride tetrahydrate is dissolved in the beaker of 10mL acetic acid (mass fraction is 1%), slowly drop in the chitosan copper solution after dissolving completely, stir 1h at room temperature, obtain chitosan-copper-iron Complex precursor solution (containing ferrous chloride 0.16mol / L, containing copper acetate 0.06mol / L). Use a syringe pump to drop the precursor solution into a sodium hydroxide solution with a concentration of 2 mol / L at a rate of 1.0 mL / min to form pel...

Embodiment 2

[0055] Change the quality 4.9703g of ferrous chloride tetrahydrate into 3.4792g in Example 1, all the other are the same as Example 1, prepare magnetic Cu(I) microsphere catalyst, take it out and air-dry naturally when used.

Embodiment 3

[0057] Change the quality 4.9703g of ferrous chloride tetrahydrate into 3.9762g in Example 1, all the other are the same as Example 1, prepare magnetic Cu(I) microsphere catalyst, take it out and air-dry naturally when used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com