A kind of two-dimensional carbon-nitrogen-based composite material photocatalyst and its preparation method and application

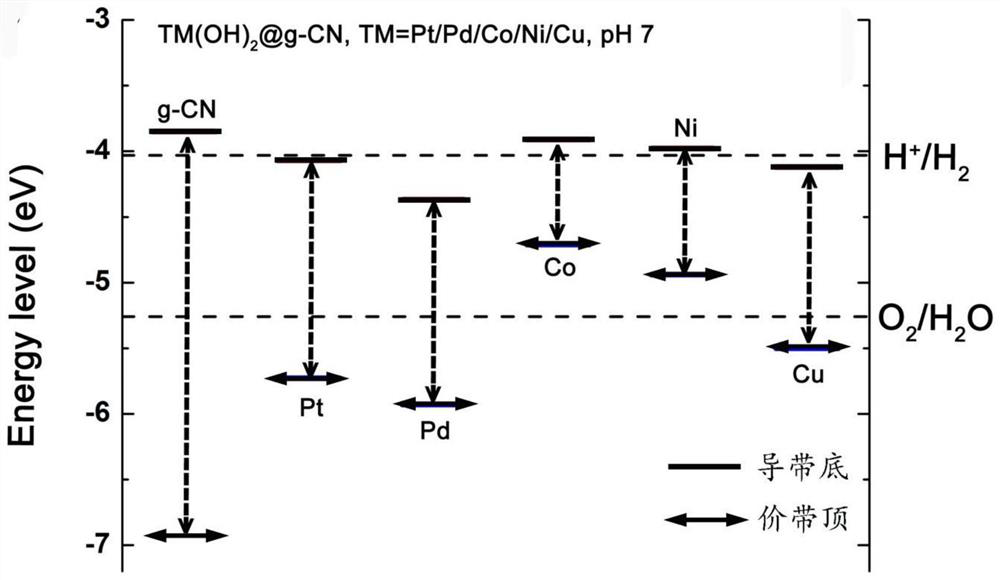

A technology of composite materials and carbon-nitrogen materials, applied in the field of photocatalytic materials, can solve the problems of reducing the band gap of photocatalysts, and achieve the effects of separating charges, suppressing reverse reactions, and improving effective transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The two-dimensional carbon-nitrogen material used in the present invention can be a single-layer two-dimensional carbon-nitrogen material, or a multi-layer two-dimensional carbon-nitrogen material. Among them, the single-layer carbon-nitrogen material is preferably a graphite-like phase nitrogen carbide material, including but not limited to single-layer CN, single-layer C 2 N or single layer C 3 N 4 . The present invention has no special limitation on the source of the single-layer or multi-layer carbon-nitrogen material, which may be commercially available or prepared according to methods well known to those skilled in the art.

[0032] The preparation of single-layer graphite-like nitrogen carbide material CN is as follows:

[0033] S1, the C 3 h 6 N 6 React in a muffle furnace at a heating rate of 12°C / min to 500°C for 4 hours, and the reaction is carried out in an atmospheric environment;

[0034] S2. Take 600mg of the product obtained in S1, put it in a muf...

Embodiment 2

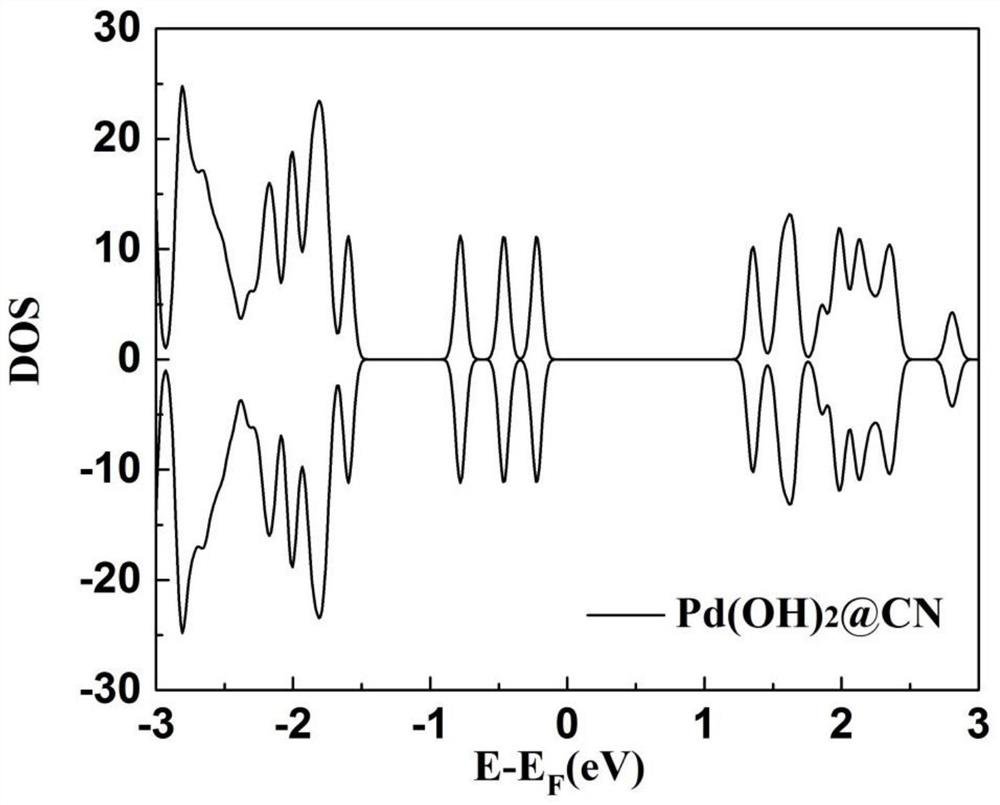

[0037] The single-layer carbon-nitrogen material CN prepared in Example 1 is used as a raw material to prepare a Pd-loaded carbon-nitrogen-based composite material, which is prepared as follows:

[0038] S1. Disperse CN in 1-butyl-3-methylimidazolium salt solution, add KOH and sonicate for 30 minutes.

[0039] S2. After ultrasonication, the solution is uniformly dispersed, and Na 2 PdCl 4 Stir at room temperature for 30 min.

[0040] S3. Add ascorbic acid and stir at room temperature for 30 minutes, then raise the temperature to 90° C., stir and react for 6 hours, and then cool.

[0041] S4. Finally, wash with ethanol and deionized water for several times to obtain.

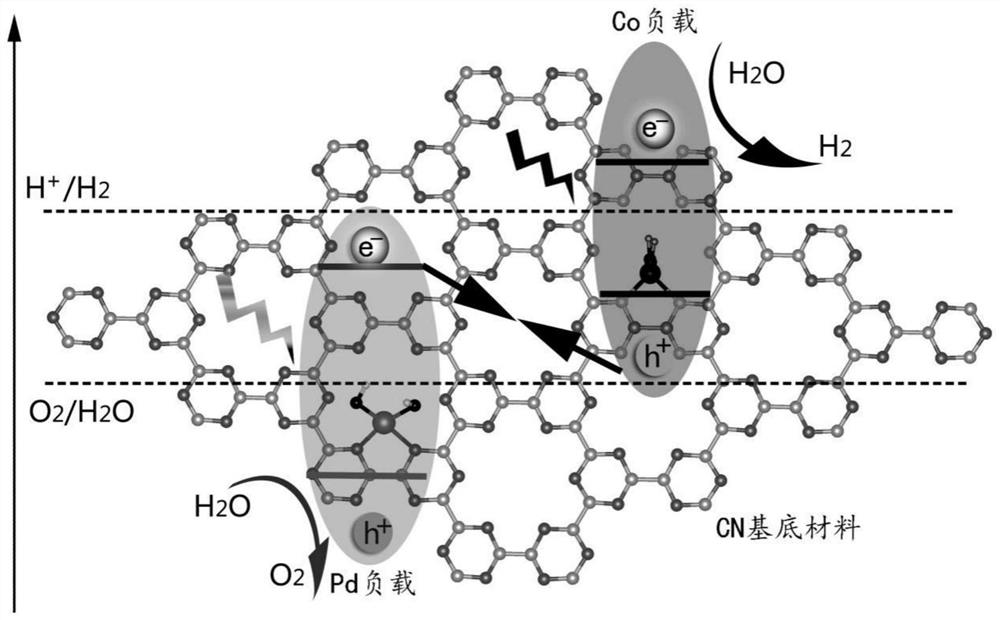

[0042] Using the single-layer carbon-nitrogen material CN prepared in Example 1 as a raw material to prepare a Co-loaded carbon-nitrogen-based composite material, the difference between its preparation and the preparation method of the Pd-loaded carbon-nitrogen-based composite material is that acetic acid is add...

Embodiment 3

[0048] The carbon-nitrogen-based composites co-loaded with Pd and Co were prepared as follows:

[0049] S1. Disperse the Pd-loaded carbon-nitrogen-based composite material prepared in Example 2 in water to prepare 200 mL of a mixed suspension of 0.1 mg / mL, then add 700 μL of 25 wt % ammonia, mix well by ultrasonication for 1 h, and then add 80 μL of hydrazine , after reacting at 95° C. for 6 h, vacuum filter with a mixed cellulose ester membrane filter, peel the product from the filter membrane, and freeze-dry to obtain a Pd-loaded film;

[0050] S2, using the carbon-nitrogen-based composite material loaded with Co prepared in Example 3 as a raw material, adopt the same method in S1 to obtain a Co-loaded film;

[0051] S3, fixedly connecting the Pd-loaded thin film and the Co-loaded thin film to the same base material silicon wafer, so as to obtain a carbon-nitrogen-based composite material loaded with Pd and Co together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com