A kind of preparation method of nitrogen-doped graphene-supported ir-ru catalyst for spe electrolysis cell

A nitrogen-doped graphene and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that the actual utilization rate of Ir-Ru catalyst is less than 30%, and achieve an improvement The effect of performance and stability, cost reduction, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

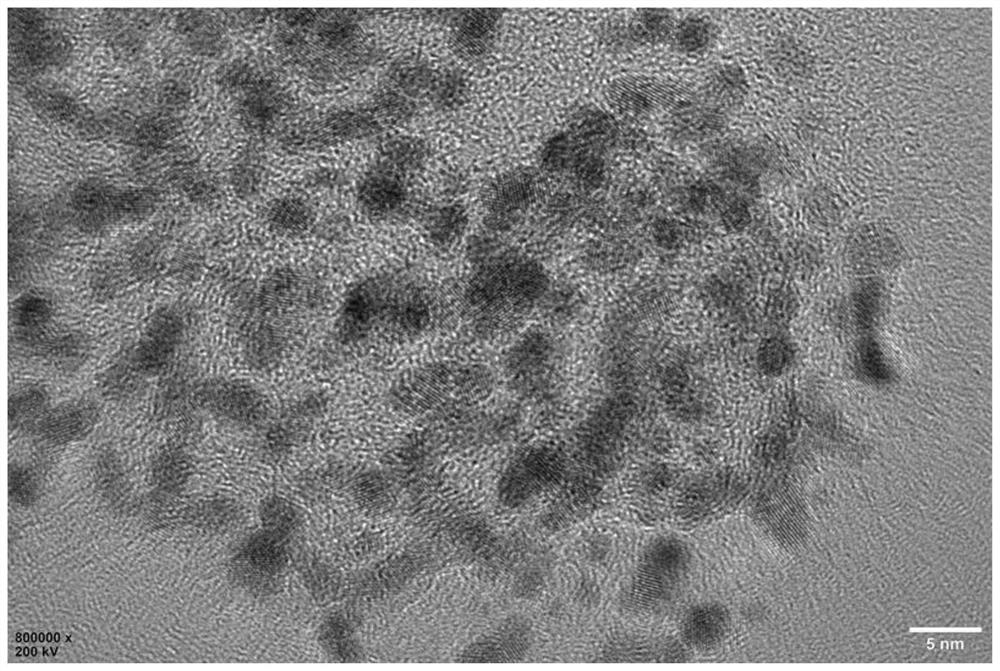

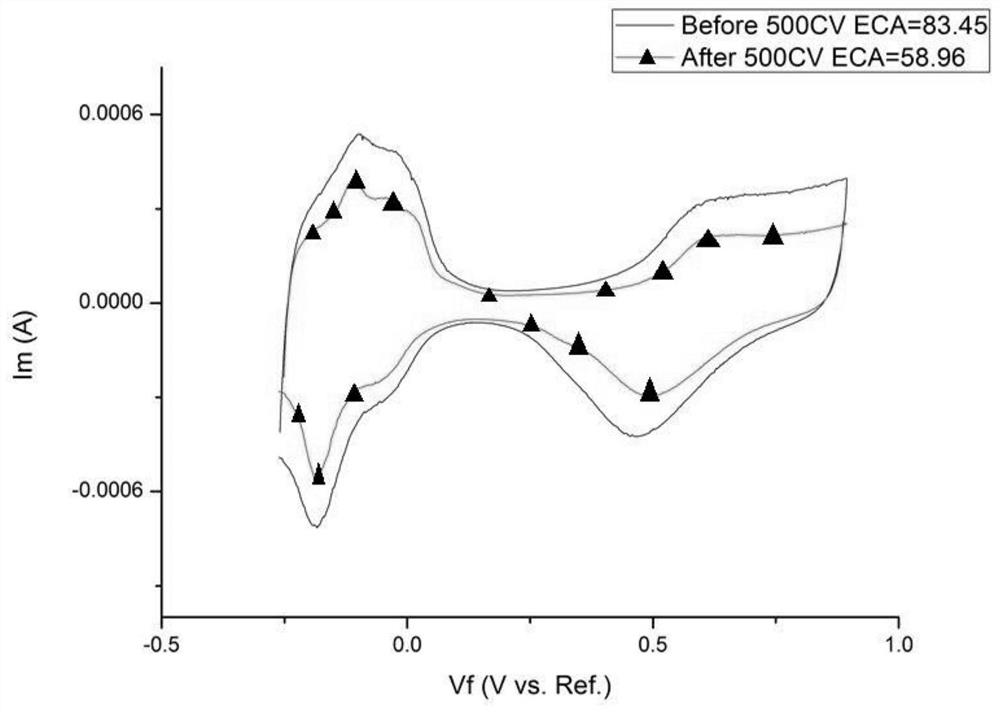

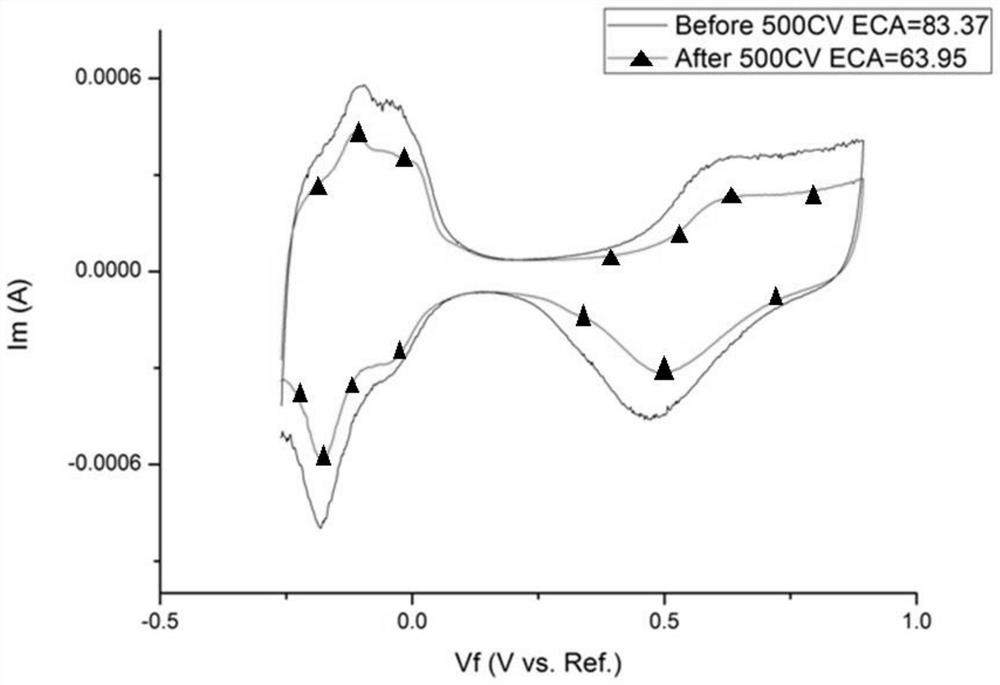

Image

Examples

Embodiment 1

[0046]1. Preparation of catalyst

[0047] 1. Dissolve 1g graphene in 10ml of melamine aqueous solution with a concentration of 0.03g / mL, immerse it for 10h, place it in a vacuum drying oven at 80°C for 15h, and place it in N 2 Heat treatment at 500 °C for 2 h in an atmosphere, and grind for later use.

[0048] 2. Take 0.18 g of the treated graphene powder and place it in an autoclave, add an aqueous solution of perfluoro 3,6-dioxa-4-methyl-7-octenesulfonyl fluoride (PSVE) monomer, add all Fluoxoic acid peroxide is used as an initiator, and tetrafluoroethylene gas is introduced for radical solution polymerization, and an appropriate amount of perfluoroSO is wound on the sphere of nitrogen-doped graphene powder. 2 F polymer.

[0049] 3. Wrap the above with an appropriate amount of perfluoroSO 2 After cleaning and drying, the nitrogen-doped graphene powder of the F polymer is immersed in an aqueous sodium hydroxide solution for hydrolysis, and the SO2 on the polymer is 2 Conv...

Embodiment 2

[0066] Preparation of catalyst

[0067] 1. Dissolve 1g of XC-72 graphene carrier in 15ml of melamine aqueous solution with a concentration of 0.03g / mL, soak it for 10h, place it in a vacuum drying oven at 80°C for 15h, and place it in a N 2 Heat treatment at 500 °C for 2 h in an atmosphere, and grind for later use.

[0068] 2. Take 0.12g of the treated graphene powder and place it in an autoclave, add an aqueous solution of perfluoro 3,6-dioxa-4-methyl-7-octenesulfonyl fluoride monomer, add disazo The compound is used as an initiator, and tetrafluoroethylene gas is introduced to carry out radical solution polymerization, and an appropriate amount of perfluoro SO is wound on the sphere of nitrogen-doped graphene powder. 2 F polymer.

[0069] 3. Wrap the above with an appropriate amount of perfluoroSO 2 After cleaning and drying, the nitrogen-doped graphene powder of the F polymer is immersed in an aqueous potassium hydroxide solution for hydrolysis, and the SO2 on the polyme...

Embodiment 3

[0077] 1. Dissolve 1 g of EC-300 graphene carrier in 20 mL of an aqueous solution of pyridine with a concentration of 0.05 g / mL, immerse it for 10 h, place it in a vacuum drying oven at 80 °C for 15 h, and place it in N 2 Heat treatment at 500 °C for 2 h in an atmosphere, and grind for later use.

[0078] 2. Take 0.12 g of the treated graphene powder and place it in an autoclave, add an aqueous solution of perfluoro 3,6-dioxa-4-methyl-7-octenesulfonyl fluoride (PSVE) monomer, add all Fluoxoic acid peroxide is used as an initiator, and tetrafluoroethylene gas is introduced for radical solution polymerization, and an appropriate amount of perfluoroSO is wound on the sphere of nitrogen-doped graphene powder. 2 F polymer.

[0079] 3. Wrap the above with an appropriate amount of perfluoroSO 2 After cleaning and drying, the nitrogen-doped graphene powder of the F polymer is immersed in an aqueous sodium hydroxide solution for hydrolysis, and the SO2 on the polymer is 2 Conversion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com