Reaction kettle with composite sight glass device

A technology for reactors and reactor bodies, applied in the field of reactors with compound mirror devices, can solve the problems of low automation, long production cycle, poor feeding accuracy, etc., achieve high automation, reduce work intensity, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

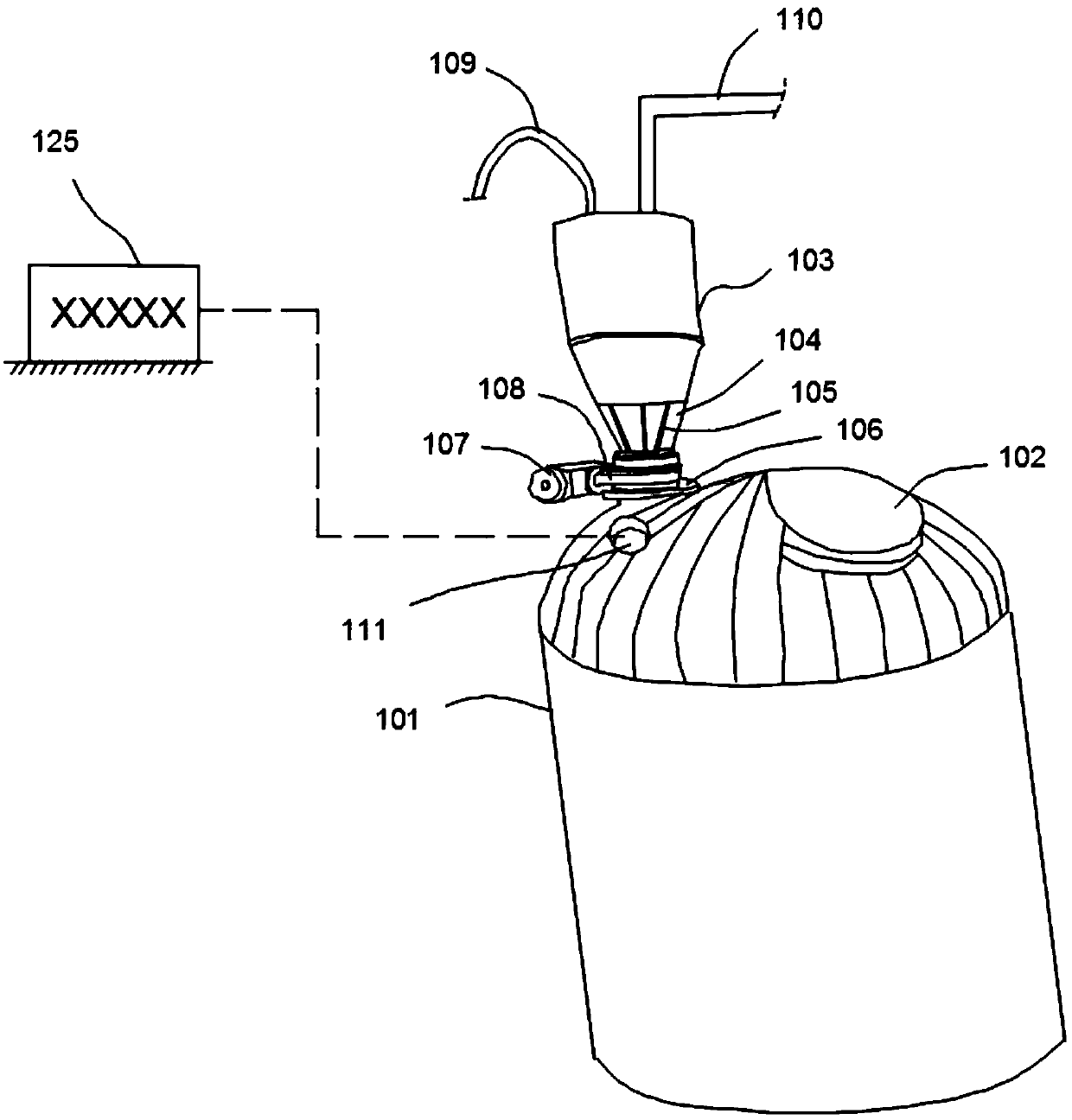

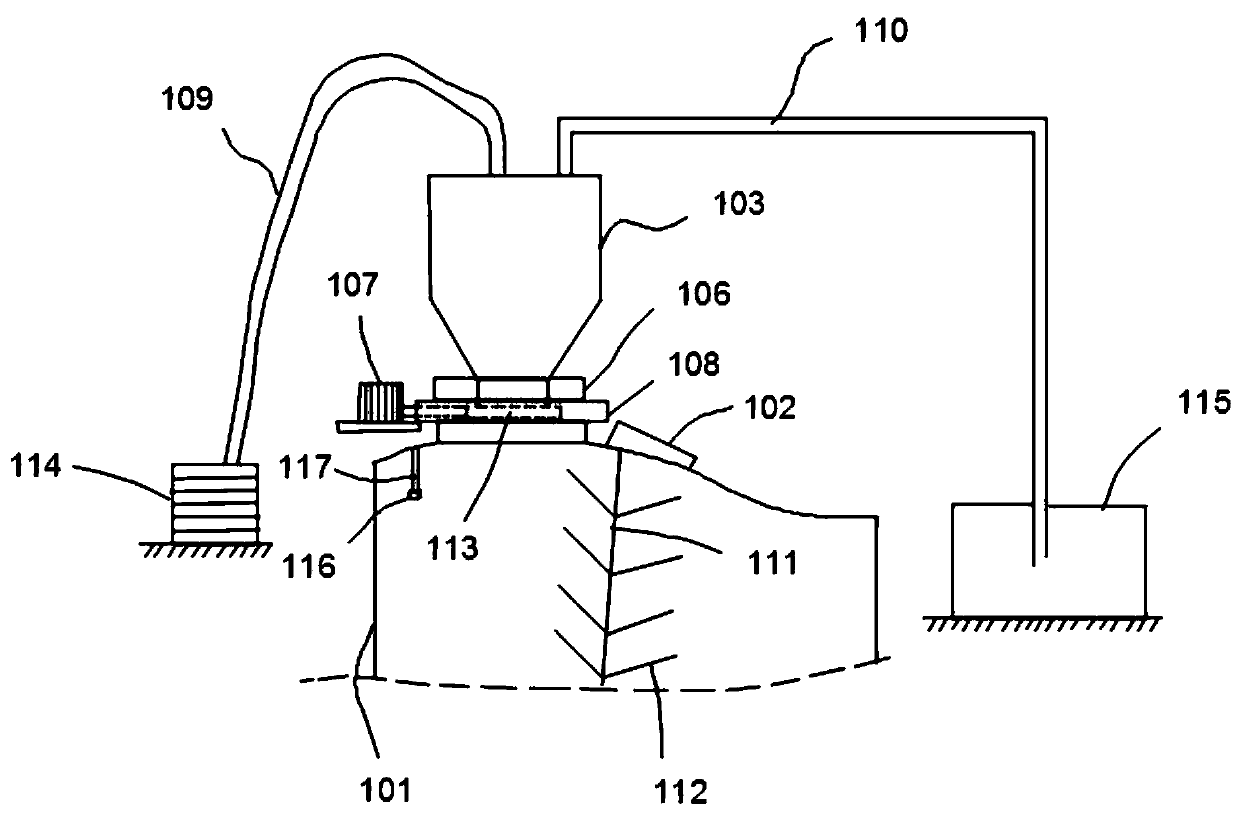

[0048] Such as figure 1 As shown, this embodiment provides a reactor with a compound mirror device, which includes a reactor body 101, a compound mirror device, a feeding bin 103, a negative pressure device 11, a pneumatic switch, a stirring device and a display device.

[0049] Wherein, the reactor body 101 is the main body structure of the reactor, and its top is provided with a tank cover 102. The inside of the reactor body 101 has a space for material reaction and a stirring device for stirring the slurry. The upper part of the reactor body 101 is provided with There is a feed channel 106, and the lower part of the reactor body 101 is provided with a discharge channel.

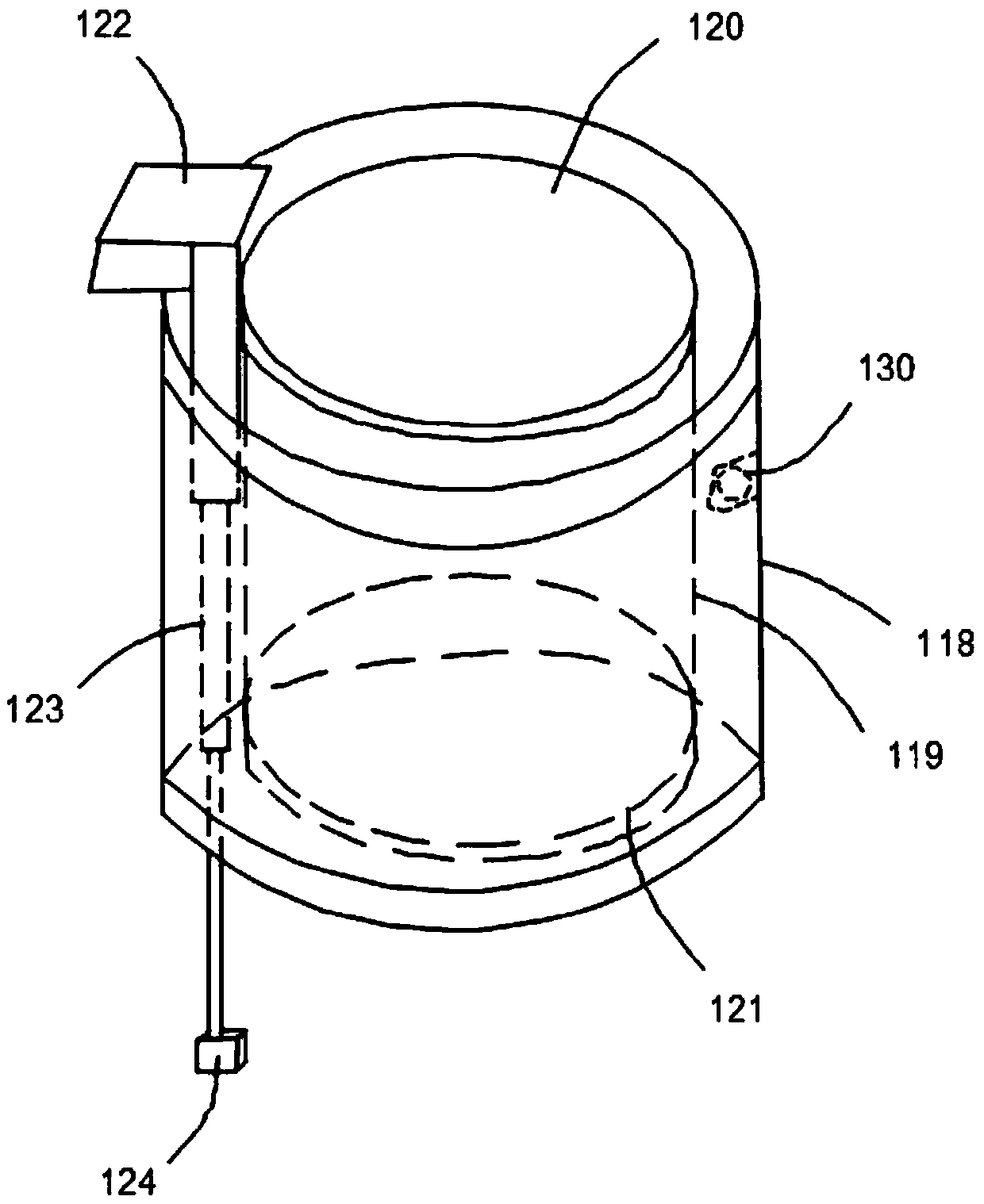

[0050] In this example, if figure 2 As shown, the composite mirror assembly includes an outer shell 118 , an inner shell 119 , a mirror assembly, a lift assembly, and a recorder 116 . Wherein, the viewing mirror assembly includes a plurality of highly transparent ceramic lenses, preferably, there are tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com