Lubricating grease composition

A technology of lubricating grease composition and solid lubricant, applied in the directions of lubricating composition, thickener, base material, etc., can solve the problems of not considering low temperature torque characteristics, high temperature shear stability and high temperature oil separation characteristics, etc. The effect of excellent low temperature torque characteristics and high static friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

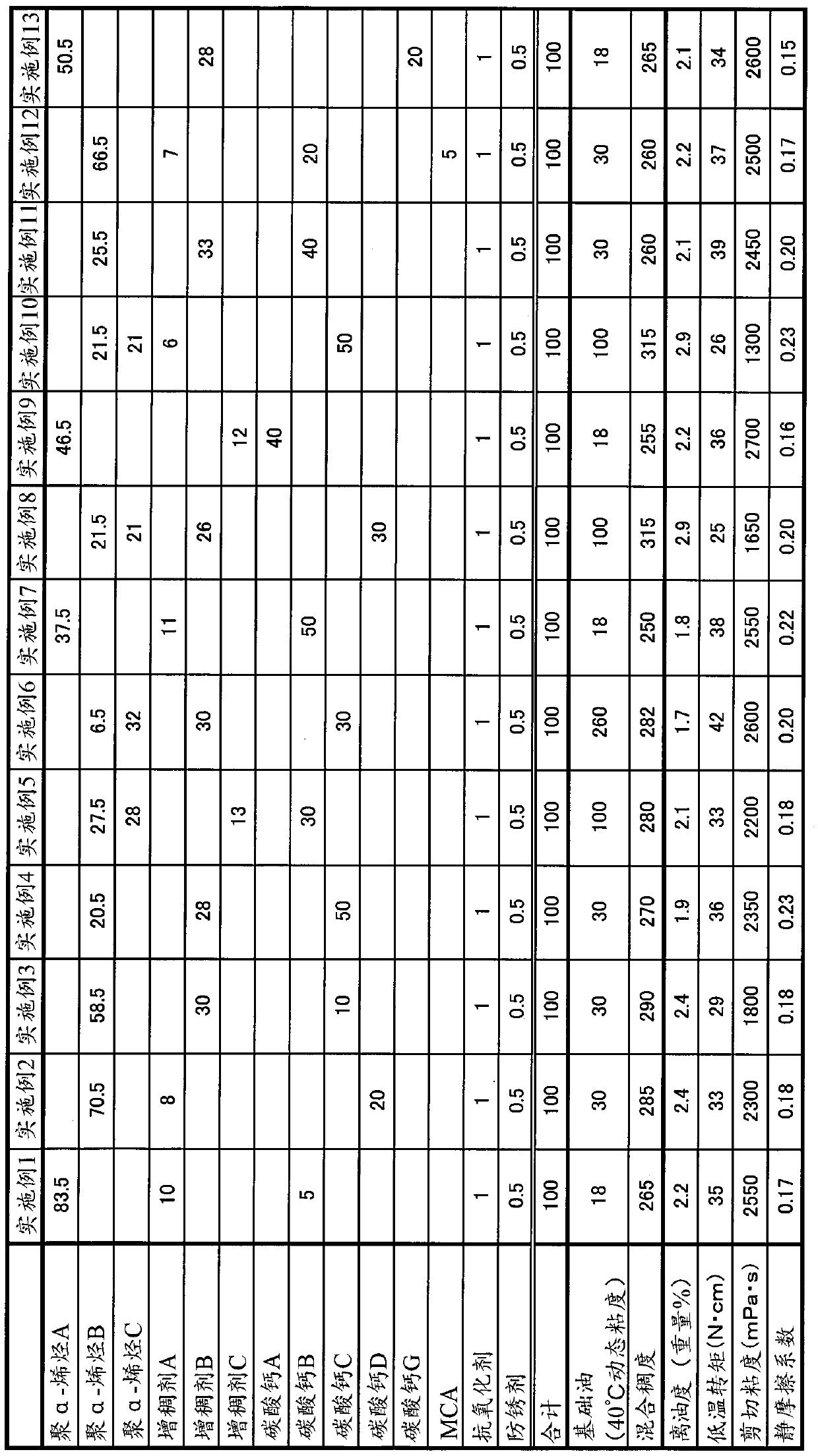

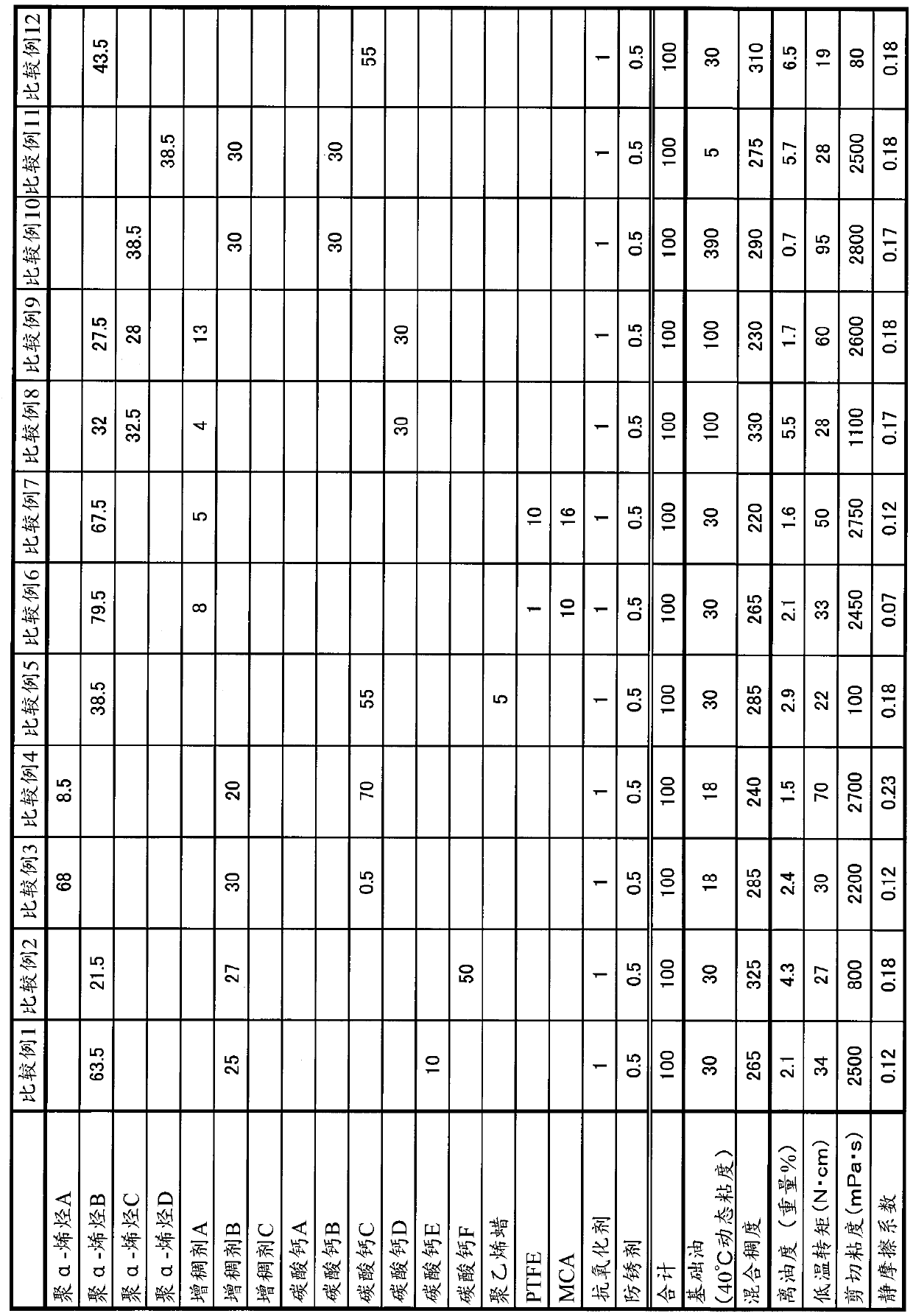

[0031] Preferred embodiments of the present invention will be specifically described below based on Examples and Comparative Examples, but the present invention is not limited to these Examples.

[0032] (1) Preparation method of grease composition

[0033] A grease composition (sample oil) was prepared, and the following components were adjusted to the compounding quantities (% by weight) shown in Table 1 and Table 2.

[0034]

[0035] Polyα-olefin A: The product name is "DURASYN164" (manufactured by INEOS OLIGOMERS JAPAN CORPORATION, dynamic viscosity at 40°C is 18mm 2 / s)

[0036] Polyα-olefin B: the product name is "DURASYN166" (manufactured by INEOS OLIGOMERS JAPAN CORPORATION, dynamic viscosity at 40°C is 30mm 2 / s)

[0037] Polyα-olefin C: the product name is "DURASYN174" (manufactured by INEOS OLIGOMERS JAPAN CORPORATION, dynamic viscosity at 40°C is 390mm 2 / s)

[0038] Polyα-olefin D: The product name is "DURASYN162" (manufactured by INEOS OLIGOMERS JAPAN CORP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com