Device and method for improving bonding performance of polyimide substrate actuator by using low-temperature plasma

A low-temperature plasma and polyimide-based technology, applied in the field of plasma, can solve the problems of poor adhesion of barrier discharge plasma actuators, etc., and achieve the effect of enhanced adhesion characteristics, simple process, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments. Embodiments are carried out on the premise of the technical solutions of the present invention, and detailed implementation methods and specific operation processes are provided, but the protection scope of this patent is not limited to the following embodiments.

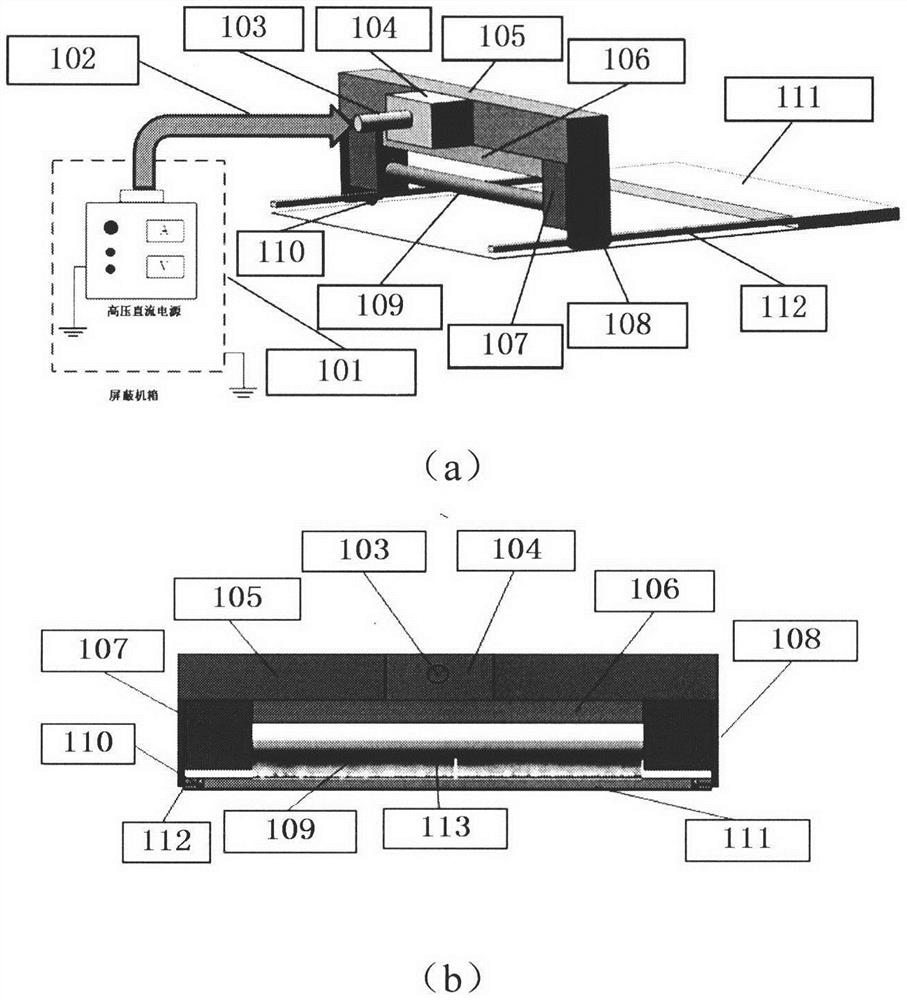

[0036] Such as figure 1 As shown, the surface layer modifying device for plasma actuator bonding performance includes a high-voltage DC power supply 101, a DC voltage power supply output terminal 102, an insulating handle 103, a first insulator 104, a second insulator 105, a third insulator 106, and a fourth insulator 107, the fifth insulator 108, discharge anode 109, pulley 110, cathode metal plate 111, slideway 112 and plasma discharge region 113 ( figure 1 shown in b). Wherein, the DC voltage power output terminal 102 of the high-voltage DC power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com