Improved current-doubling rectifying circuit

A current doubler rectification and improved technology, which is applied in the direction of converting AC power input to DC power output, electrical components, irreversible AC power input to DC power output, etc. Problems such as hindering the development of current doubler rectifier circuit, to achieve the effect of reducing volume and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

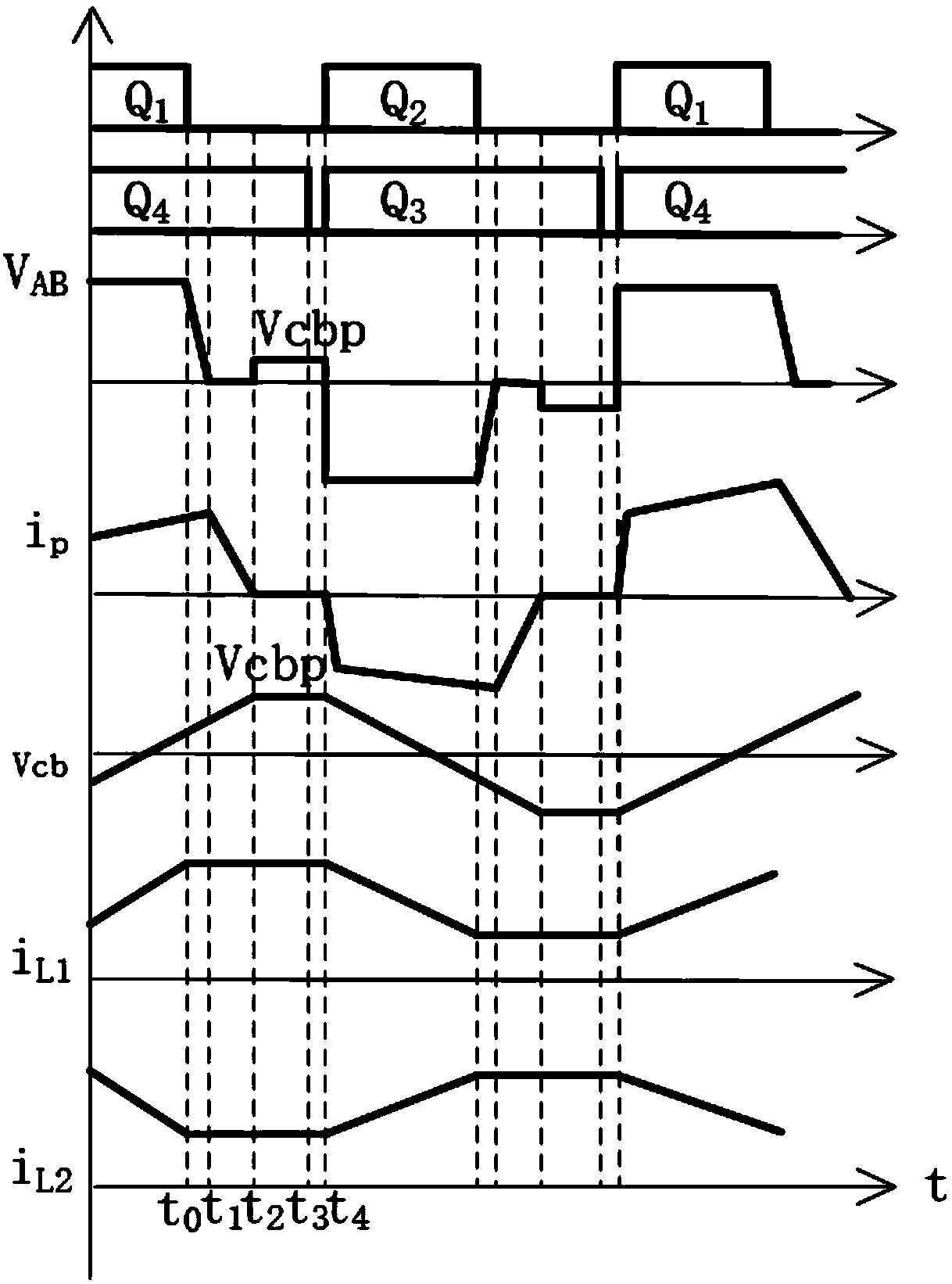

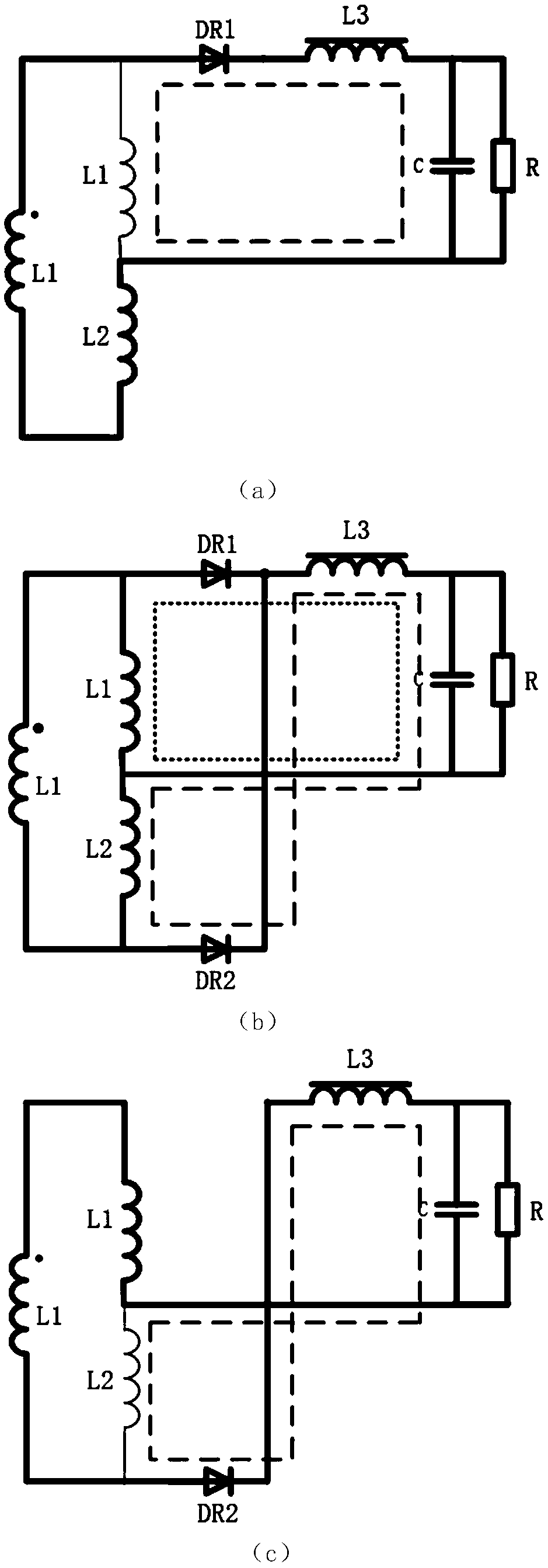

[0012] The specific implementation of this circuit is as follows:

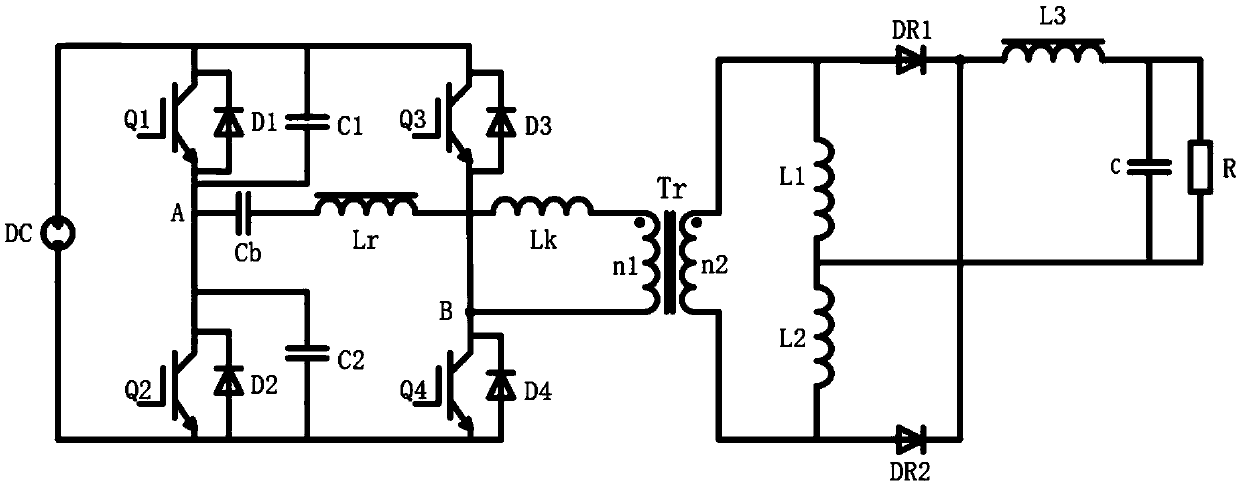

[0013] Such as figure 1 As shown, the present invention uses a full-bridge inverter circuit and a current doubler rectification improved circuit topology to build, mainly including: a direct current power supply DC, a first switching tube Q1, a second switching tube Q2, a third switching tube Q3, and a fourth switching tube Tube Q4, first switching tube parallel capacitor C1, second switching tube parallel capacitor C2, first switching tube parallel diode D1, second switching tube parallel diode D2, third switching tube parallel diode D3, fourth switching tube parallel diode D4 , DC blocking capacitor Cb, saturated inductance Lr, transformer leakage inductance Lk, transformer Tr, transformer primary winding n1, transformer secondary winding n2, first inductance L1, second inductance L2, third inductance L3, first diode DR1, a second diode DR2, a filter capacitor C, and a load R.

[0014] The full-bridge inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com