Hydrogen sensor and preparation method thereof

A sensor and hydrogen technology, applied in the field of high-sensitivity hydrogen sensors, can solve the problems of inconvenient hydrogen storage and use, non-continuous measurement, and limited electrode life, and achieve wide selectivity, scalability, strong resistance to electromagnetic interference, and measurement small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

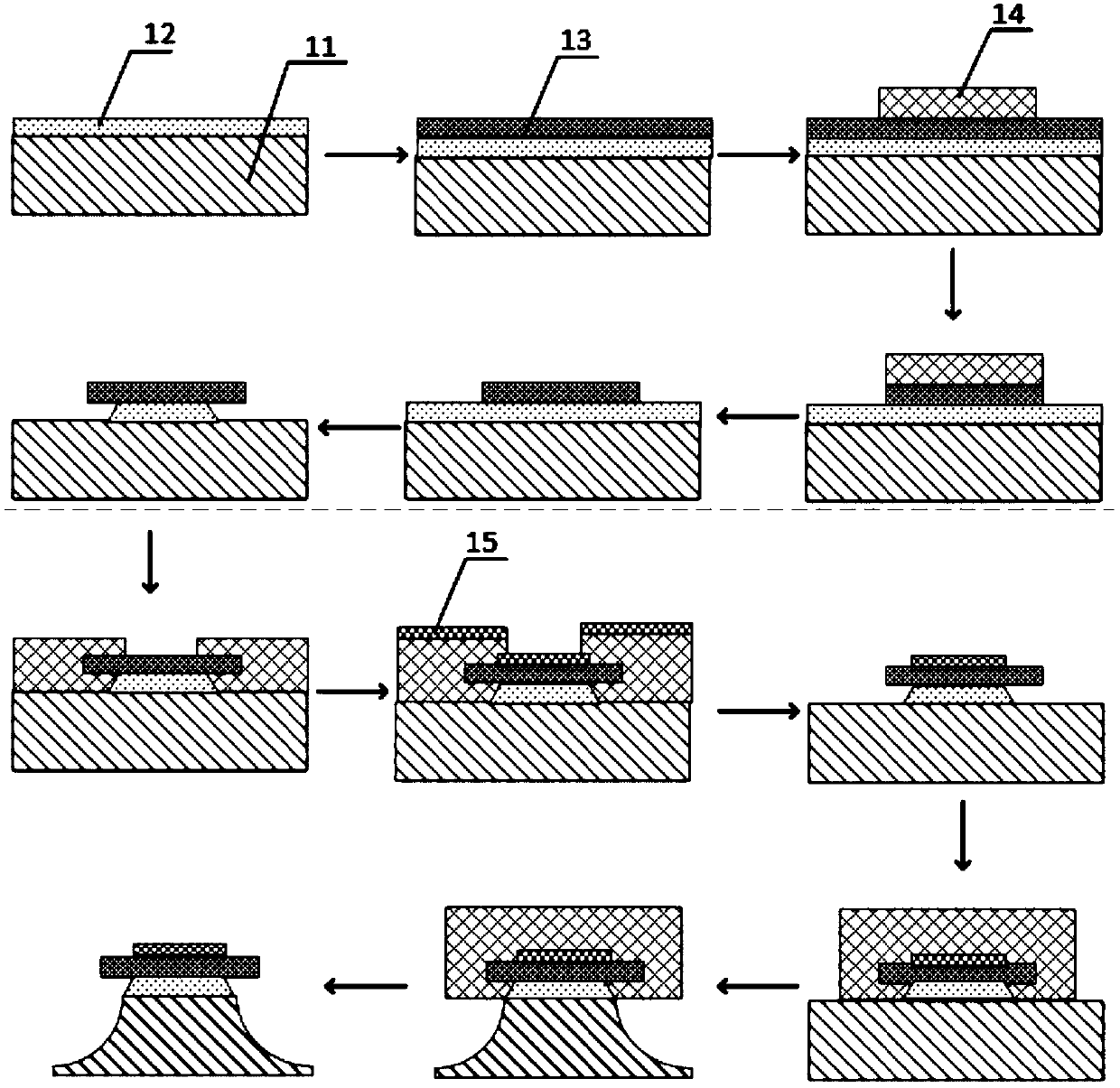

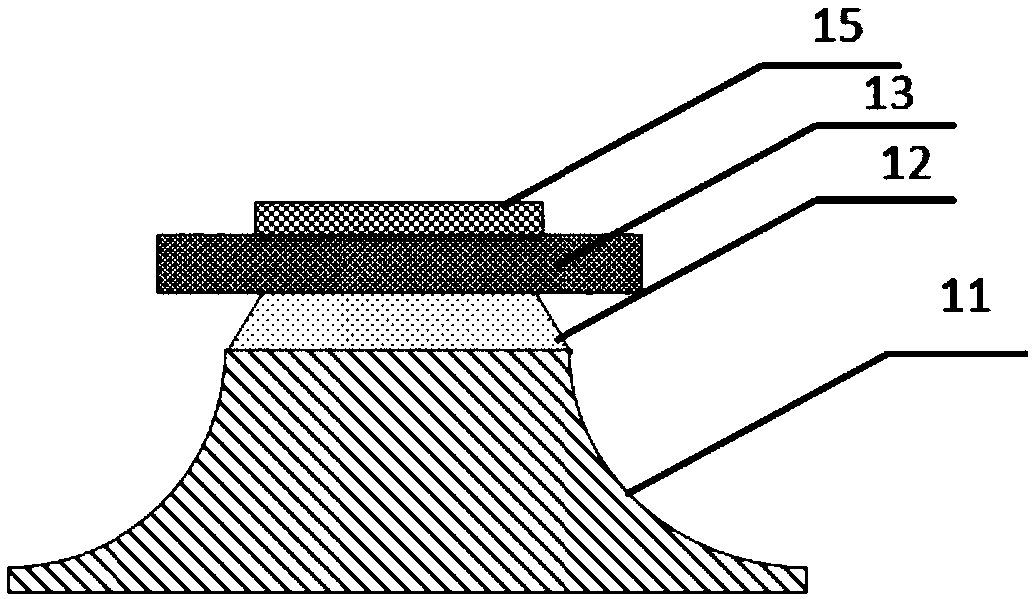

[0041] Such as figure 2 As shown, a hydrogen sensor based on a chalcogenide soft glass optical microdisk cavity, including a microdisk cavity substrate and a 1 μm thick SiO2 layer prepared sequentially on the substrate from bottom to top 2 Protective layer, 1.36μm thick Ge 11.5 As 24 Se 64.5 Thin-film microdisk cavity, 250nm-thick metal palladium thin-film hydrogen absorption layer.

[0042] Ge 11.5 As 24 Se 64.5 The cavity of the film microdisk is uniform and flat, and has strong adhesion. The metallic palladium thin film is selectively deposited on the chalcogenide thin film to weaken the impact on light wave transmission when fully covered.

[0043]The substrate is a structure with a narrow top and a wide bottom, and the side wall is an inwardly concave curved surface, so as to maximize the suspended length of the chalcogenide soft glass microdisk cavity, so that the hydrogen absorption layer can be transferred to the corresponding shape on the chalcogenide glass. ...

Embodiment 2

[0055] Such as figure 2 As shown, a hydrogen sensor based on a chalcogenide soft glass optical microdisk cavity, including a microdisk cavity substrate and a 1 μm thick SiO 2 Thermal oxide protective layer, 1μm thick As 2 S 3 Thin-film microdisk cavity, 150nm-thick metal palladium thin-film hydrogen absorption layer.

[0056] As 2 S 3 The cavity of the film microdisk is uniform and flat, and has strong adhesion. The metallic palladium thin film is selectively deposited on the chalcogenide thin film to weaken the impact on light wave transmission when fully covered.

[0057] The substrate is a structure with a narrow top and a wide bottom, and the side wall is an inwardly concave curved surface, so as to maximize the suspended length of the chalcogenide soft glass microdisk cavity, so that the hydrogen absorption layer can be transferred to the corresponding shape on the chalcogenide glass. The more pronounced the variable, the higher the corresponding sensitivity.

[0...

Embodiment 3

[0068] Such as figure 2 As shown, a hydrogen sensor based on a chalcogenide soft glass optical microdisk cavity, including a microdisk cavity substrate and a 1 μm thick SiO2 layer prepared sequentially on the substrate from bottom to top 2 Thermal oxide protective layer, 1μm thick Ge 11.5 As 24 Se 64.5 Thin-film microdisk cavity, 180nm-thick metal palladium thin-film hydrogen absorption layer.

[0069] Ge 11.5 As 24 Se 64.5 The cavity of the film microdisk is uniform and flat, and has strong adhesion. The metallic palladium thin film is selectively deposited on the chalcogenide thin film to weaken the impact on light wave transmission when fully covered.

[0070] The substrate is a structure with a narrow top and a wide bottom, and the side wall is an inwardly concave curved surface, so as to maximize the suspended length of the chalcogenide soft glass microdisk cavity, so that the hydrogen absorbing layer can be transferred to the corresponding shape on the chalcogeni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com