Sealing bearing for ship underwater device

An underwater device and sealed bearing technology, applied in the field of sealed bearings, can solve the problems of inability to withstand radial force, low pressure resistance, and easy aging of rubber sealing rings, and achieve compact and flexible structure, strong pressure resistance, and bearing capacity. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

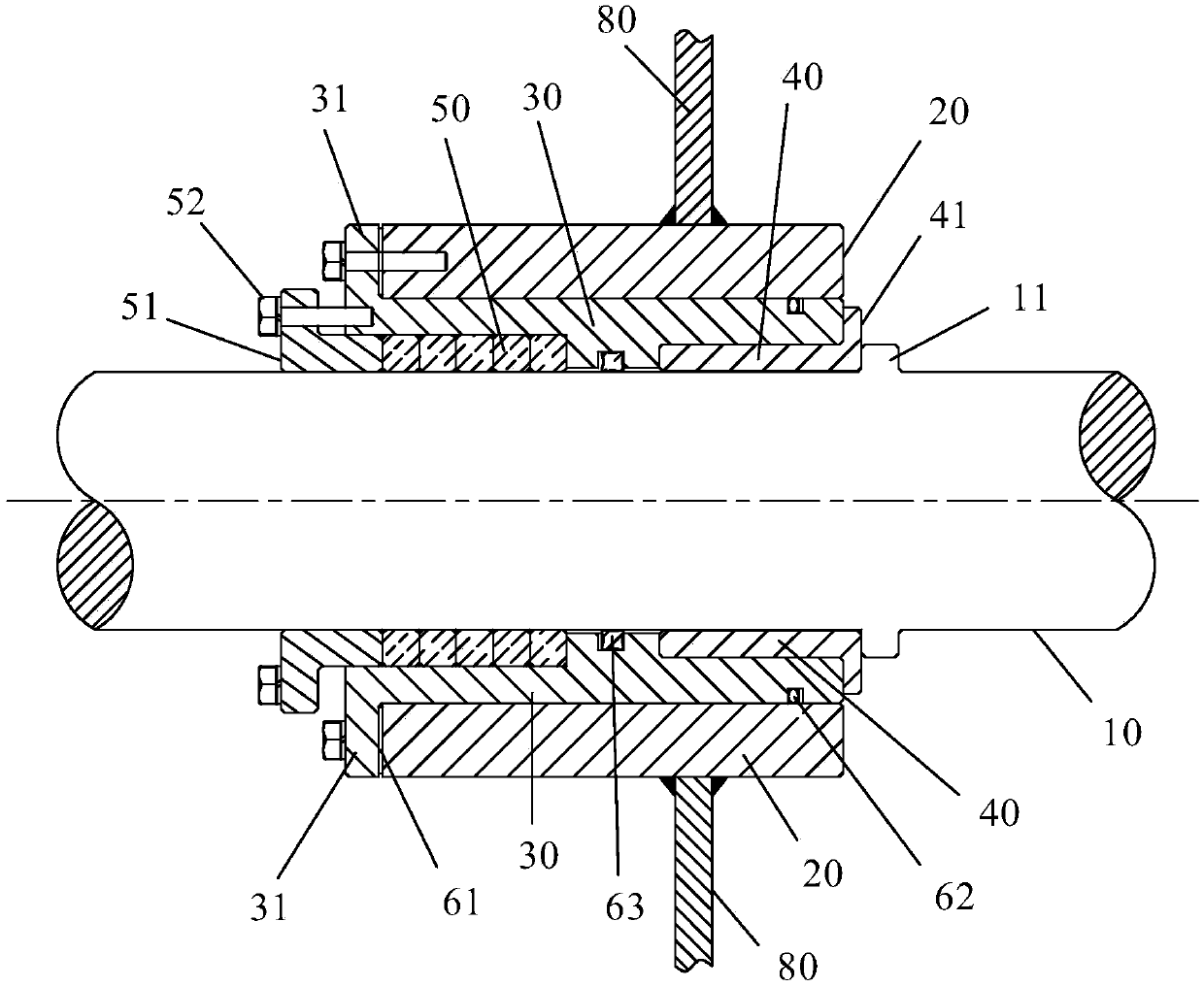

[0021] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

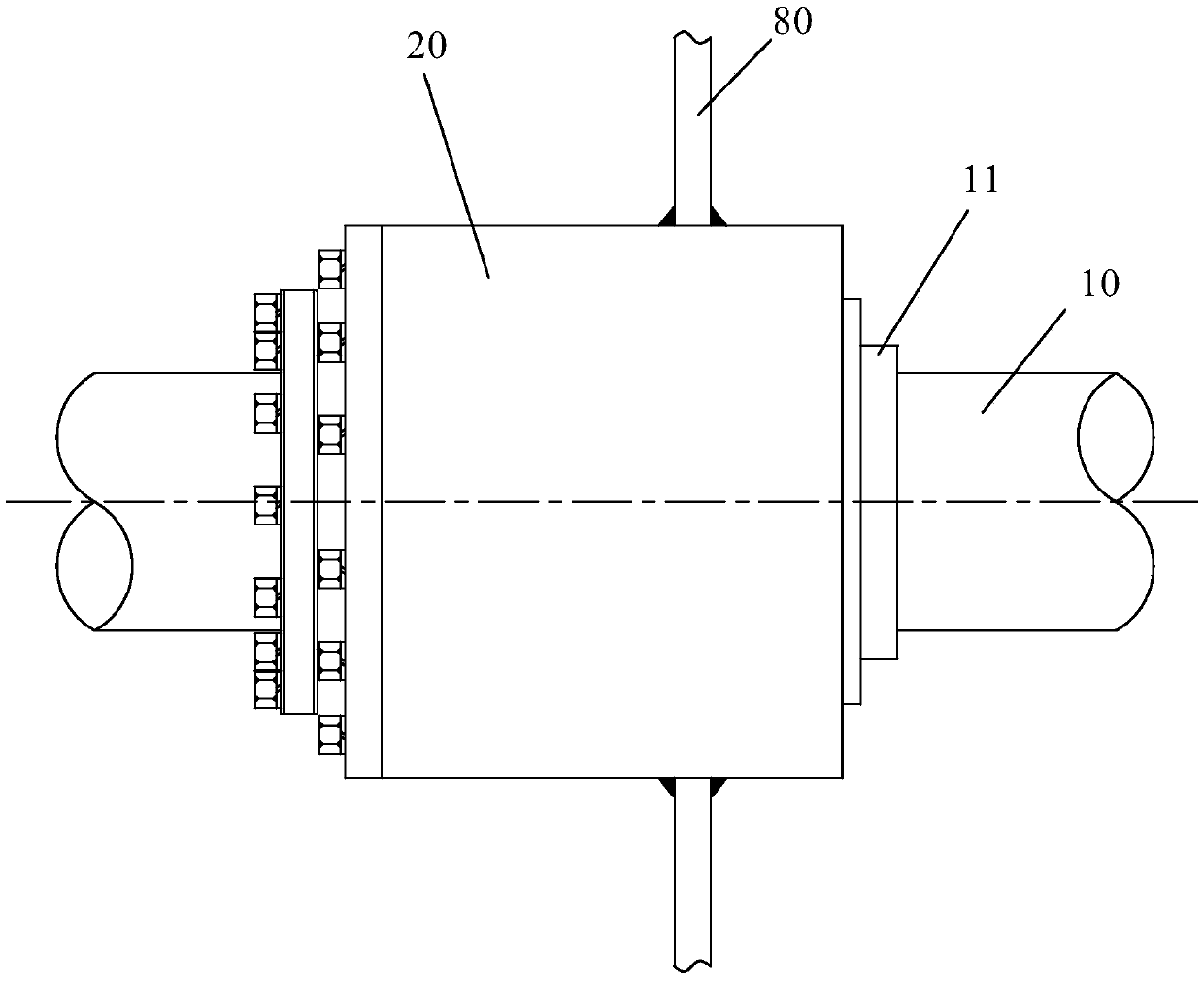

[0022] like figure 1 and figure 2 As shown, a sealed bearing for marine underwater devices includes an outer bearing 20 sheathed on a transmission shaft 10 , and an inner bearing 30 is provided on the inner wall of the outer bearing 20 . Both the outer bearing and the inner bearing are tubular.

[0023] The left end of the inner seat 30 has a connecting portion 31 , the connecting portion 31 extends toward the outer side of the outer seat, and the connecting portion 31 is fixedly connected to the left end of the outer seat 20 . In this embodiment, the connection part and the outer bearing are connected by bolts.

[0024] A first seal 61 is provided between the connecting portion 31 and the outer seat 20 . The first seal 61 is a rubber gasket. The first seal can achieve a seal between the inner and oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com